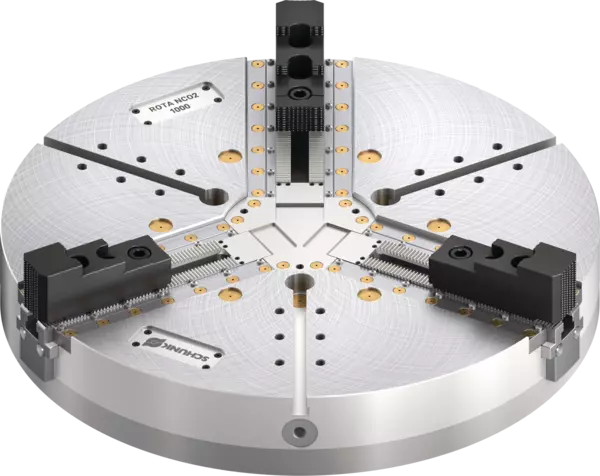

ROTA NCO2

3-jaw power chuck without through-hole

Large, weight-optimized 3-jaw power chuck with improved sealing and large jaw stroke

Description

Advantages – Your benefits

- Precision wedge-hook power lathe chuck for highest quality requirements

Allows excellent machining processes - High efficiency of the wedge hook system

Process-reliable clamping due to high clamping forces - Optimum jaw support for O.D. and I.D. clamping due to a very long base jaw guidance

Allows high clamping forces at a long service life - Optimized lubrication system

Consistently high clamping forces are ensured - Largest jaw stroke at high jaw clamping force

Reliable and variable clamping of workpieces over interfering contours - Low height

Maximum use of the machine room and maximum rigidity of the system - Weight-optimized cast body

Reduced energy consumption and higher workpiece weights possible - Modul 2 serration

For simple setup and cleaning - Optionally available with centrifugal force compensation

Less clamping force loss at high RPM - Optionally available with individual jaw adjustment

Workpieces can be optionally aligned to the rotation center

Options and special information

- Large 3-jaw power lathe chucks for vertical lathes

The ROTA NCO2 combines highest clamping forces with a large jaw stroke. This makes it possible to securely clamp large and heavy workpieces even in case of an interfering contour. A sophisticated lubrication system and a seal on the base jaw ensure reduced maintenance costs and a longer chuck life. - In addition to the standard variant, the chuck is also available as a variant with centrifugal force compensation or with individual jaw adjustment. This allows the chuck to cover an even wider range of tasks and to be optimally selected for the individual clamping task. The ROTA NCO2 is ideal for vertical turning applications.