At its Austrian location, SVI, a globally operating EMS provider, employs 350 people who work on a production area of 5,300 square meters to actively shape the future of automotive electronics production. With the goal of further expanding its expertise and specialization in this field, SVI Austria aims to set new standards as a strong partner for its customers.

Before working with SCHUNK Electronic Solutions, SVI Austria relied on stand-alone solutions and manual work at the end of the line. However, the demands on the processes increased – both in terms of volumes, and regarding to quality and process reliability. The existing structure reached its limits. A fully automated seamless solution became necessary. “We wanted a solution that could handle our growing production volumes while ensuring the quality of our products,” Walfred Krienzer, Project Manager at SVI Austria. “Above all, it was important to us to minimize manual intervention and remain flexible.“

SCHUNK Electronic Solutions, together with strong partners such as Achat5 Engineering GmbH – an expert for board handling solutions, Schnaidt GmbH – a specialist for equipment for electronics manufacturing, and Dr. Eschke Elektronik GmbH – a recognized expert in test systems, developed a highly automated production line that covers all process steps.

The process started with a 4-position magazine loader capable of handling up to 23 stacks of panels. These panels are then gradually transferred into the ILR-2800 via an intelligent board handling system – synchronized with a processing cycle. In this context, SCHUNK and Achat5 have further intensified their partnership: in the future, SCHUNK will offer Achat5’s board handling systems as part of its own portfolio – providing even more integration from a single source.

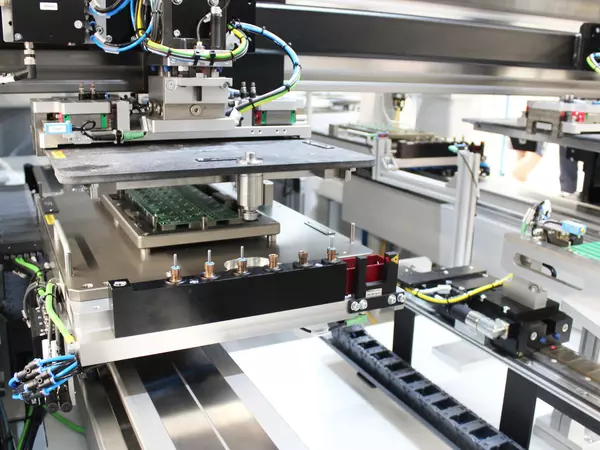

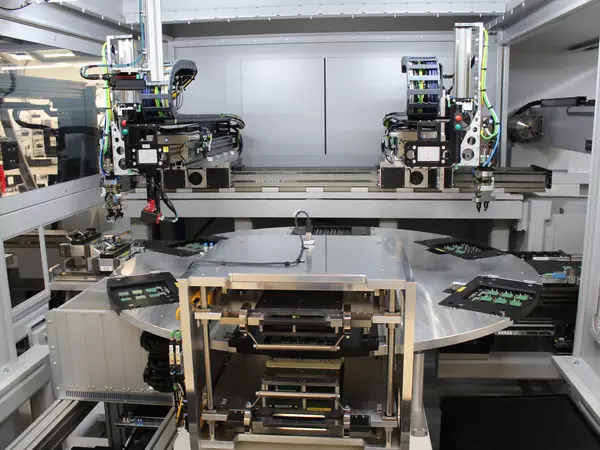

The ILR-2800 is the heart of the line, impressing with maximum precision at top speed. Two specially developed SCHUNK linear axes, extending across the entire machine, enable particularly efficient cycle times. On these axes are four positions for the workpiece carrier shuttles, which operate perfectly in sync with a time offset. This ensures continuous processing with virtually no waiting times and maximizes productivity. The workpiece carrier, developed and manufactured in cooperation with Schnaidt, as well as the complete lid station, are equipped with SCHUNK’s VERO-S quick-change pallet system – providing secure fixation and fast, precise changeovers. This is a decisive advantage for process reliability.

The sophisticated design of the ILR-2800 enables virtually uninterrupted processing. The combination of synchronized workflows and seamlessly integrated process steps – from milling to lid placement to disposal – ensures maximum machine utilization with the highest process stability.

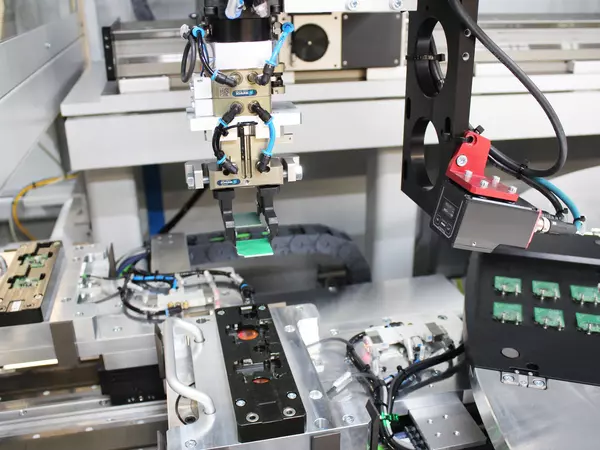

The rotary indexing cell was developed together with Schnaidt GmbH and Dr. Eschke Elektronik GmbH. It performs the in-circuit test (ICT) and ensures consistently secured product quality. “The ICT test is a central part of our production process,“ Walfred Krienzer. With the specially developed C-adapter and precisely manufactured test nests, the printed circuit boards are securely fixed during the test and checked for electrical functionality. “The seamless integration of the test saves time and reduces sources of error,” Krienzer continues.

After the testing process, the SCHUNK palletizing system PAL-1500 takes over the inspected printed circuit boards. Functions such as tray centering, ejection station, and empty tray control ensure a smooth and secure transfer to the next production stage. A separate reject parts conveyor provides safe handling of faulty components without interrupting the production flow.

Thanks to its modular design, the PAL-1500 can be flexibly adapted to different tray formats and offers maximum process reliability – particularly important for series production in automotive industry.

The production line is fully MES-capable, enabling central control and end-to-end traceability. SMEMA interfaces facilitate seamless data exchange between the machines, while scanner and set-up controls further enhance process reliability. “To meet the requirements of the automotive industry, this seamless communication is indispensable,“ emphasizes Krienzer.

Conclusion: future-proof production thanks to automation

The production line implemented at SVI Austria exemplifies successful partnership and intelligent automation. With a planned annual output of up to 4 million products, the system sets new standards in efficiency and quality. “The system operates exactly as planned, and the effort required for operation and set-up was significantly lowered than expected – this makes the entire process even more efficient,” summarizes Krienzer. Stefan Lorenz, Sales Representative at SCHUNK Electronic Solutions, adds: “The system’s flexibility allows additional processes such as laser marking or hot staking to be seamlessly integrated – perfectly tailored to the requirements of our customers.”

The automotive industry is facing challenges, but also great opportunities. Highly automated production processes are increasingly essential for securing long-term quality, scalability, and competitiveness.