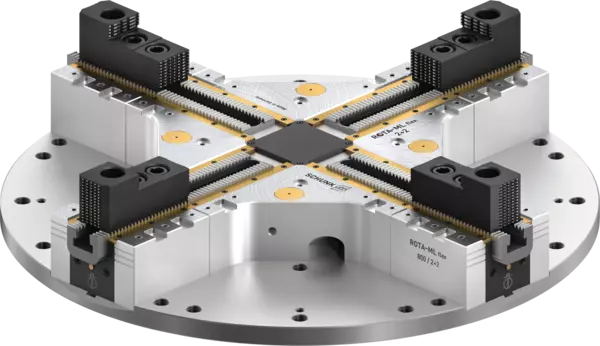

ROTA-ML flex 2+2

Flexible 4-jaw compensation chuck

Centrically compensating 4-jaw chuck with large compensation stroke.

Description

Advantages – Your benefits

- Sealed manual lathe chuck

For significantly longer maintenance intervals - Patented drive concept

Independent installation of the jaw pairs with subsequent centrically compensating workpiece clamping - Flexible clamping system

For clamping round, cubic, or geometrically bulky workpieces - Compensation mechanism

Enables centric clamping of any workpiece geometries - Optimized chuck heights and weights for the new ROTA-ML flex 2+2 versions from Ø 500 mm

For a maximum additional payload of workpiece weight - High efficiency of the wedge bar system

Process-reliable clamping due to high clamping forces - Lubrication system with grease circulation

Ensures permanent grease supply for constant clamping forces - Visual clamping release

As an indicator for the range in which safe clamping can be ensured - All sides of the functional parts are hardened and ground

Ensures a long service life

Options and special information

- Extremely flexible 4-jaw manual lathe chuck

Clamping of round, cubic and geometrically unshaped parts – no problem for the ROTA-ML flex 2+2. Thanks to the patented drive concept with coupled jaw pairs, any workpiece geometry can be clamped centrically and without overdetermination. The chucks are used in particular in storage solutions and on mill/turn machines, but can also be used on lathes. The chuck weights of the large chucks with Ø 500 mm or more have been reduced by up to 40% compared to the previous version, so that an even higher workpiece weight can be loaded.