In an increasingly electrified world, power electronics play a major role. The aim is to make electric drive systems as efficient as possible in order to use energy sparingly and sustainably. This is where Semikron Danfoss technologies are important. The company manufactures power modules, semiconductor components, switches, stacks and systems for automotive engineering, transportation systems, industrial plants and renewable energy applications. "Our aim is to offer high-performance electronic modules so that users can reduce their CO2 emissions," explains Hanno Bruss, Test Engineer at Semikron Danfoss Elektronik in Nuremberg. "State-of-the-art electronic components are the basic prerequisite for this in order to ensure that the electrical systems function perfectly and work efficiently. For us in production, the focus is therefore on zero-defect production, compact power electronics designs and high output power."

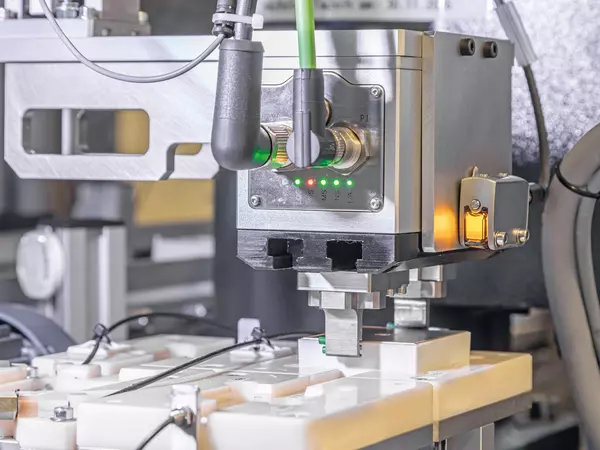

Measuring and testing technology therefore plays a central role at Semikron Danfoss. "Every single module that is produced here undergoes a comprehensive functional check. Of course, only one hundred percent iO parts leave the company." Gripping technology from SCHUNK plays a key role in this quality assurance. In a closed automation cell upstream of a measurement line, the mechatronic parallel gripper EGU handles electronic components on a Scararobot. They arrive in tray stacks and reach the inside of the cell via a destacking unit. Here, the gripper on the robot removes the components individually from the blister tray and places them on a narrow conveyor belt to feed them to the measurement line. It meticulously scrutinizes the parts by carrying out comprehensive final measurements of the static, optical, tactile, dynamic and electronic parameters. The results of each individual module are documented and stored. At the end of the quality control in the approximately six-meter-long measurement line, the products removed are marked by laser and stacked back into trays to be packaged as finished goods.

The throughput depends on the parts and the number of parameters to be measured. The measurement line currently operates in three shifts from Monday to Friday. "The key element of this system is continuous and reliable feeding of the components from the robot cell," says Hanno Bruss. "That means the gripper is particularly important." The system at the Nuremberg plant has been working with an electric gripper from the automation specialist SCHUNK for several years now. "We have been working with SCHUNK for a long time," confirms Bruss. "We use SCHUNK grippers in many other places, too. A model was installed on this cell that has been discontinued. And that's how the EGU came into the equation, which impressed us right from the start," recalls Bruss. The first inspection of the new electric parallel gripper took place at the SPS in 2022. "I was given a product to try out straight away and was able to test it in practical use," says the experienced test engineer. "From the very start, the gripper was the perfect fit and fully met all of our requirements."

Semikron Danfoss has very specific requirements for the gripper. "Firstly, we are limited in terms of weight due to the robot application. The EGU complies with this weight limit," explains Bruss. "Secondly, we need a large gripper stroke from very small to large, from around 30 to 110 millimeters. I had a good hard look around the market and tested out a variety of products myself. The flexibility of the SCHUNK gripper was a decisive factor in our choice." Hanno Bruss also pointed out that there are always different parts to be handled and that the flexibility of the gripper also affects the workpiece variance. "That's why a servo-electric gripper is the right choice here."

The test engineer emphasized that the mechatronic EGU is also preferable to a pneumatic variant in terms of component handling safety. "The EGU offers us process reliability, which is very important for operating the measuring cell." Another important advantage of using the EGU: "It works perfectly even with a short distance for the approach," says Bruss. "Because we have to drive into a pretty tight space here. Other grippers on the market required at least three to four millimeters of travel, which was too much for us. With the EGU, the short approach distance works very well and meets our requirements." The fact that the gripping force can be specially adjusted also spoke in favor of the EGU. "Maintaining the gripping force in the event of a voltage drop or loss was another selling point for us," says Bruss enthusiastically. "We have found the right gripper in the EGU. It does exactly what it is supposed to do, and it fully exploits the advantages of servo-electric gripping technology in this application."

Semikron Danfoss uses the size 50 EGU in the robot cell. This model is suitable for the "MiniSKiiP" cuboid electronic modules as well as for other component variants. The EGU is easy to integrate, flexibly adaptable and can be monitored at all times. In the event of a power failure or emergency stop, at least 90 percent of the gripping force is reliably retained. The position of the gripper fingers is known at all times by the absolute encoder on the output side so the process can continue after switch-on without re-referencing. The EGU is impressive in no small part due to its variety of interfaces and software integration. Hanno Bruss has already reordered five more EGU models and praised the effective information exchange with SCHUNK when it comes to process improvements. "For us, partnership-based cooperation is a given," emphasizes Andreas Fiederling, Technical Consultant for Gripping Technology and Automation Technology at SCHUNK. "The EGU is part of a pioneering gripper concept that SCHUNK has launched. Together with our customers, we want to make the most of every bit of potential in terms of flexibility, adaptability, future viability – and ultimately sustainability. This is best achieved at eye level."