Measuring instruments for pressure, temperature, level, flow and force are required in a wide range of different industrial and non-industrial fields. They are used in general engineering and automation technology as well as in the food and pharmaceutical industries, medical technology, power engineering, and chemical and process engineering processes. Last but not least, measuring instruments are also installed in the basements of many private households, for example on heating and air conditioning systems. Anyone who uses them, in any field, must be sure that they work properly. After all, the devices provide precisely the information that is essential for the application in question. For production, WIKA in Klingenberg am Main, Bavaria, uses manufacturing components of the highest quality – including components from SCHUNK.

"WE have traditionally used SCHUNK products in all our plants for years, both grippers, and toolholding and workholding technology," explains Michael Balles, Head of Machining and Prefabrication at WIKA. "We manufacture measuring instruments with the highest accuracy, durability, reliability and quality. That's why we use top components in production to meet the high demands." A new machine tool for five-sided machining, a Hermle C400, was added to the modern manufacturing environment at WIKA in 2022. "We have large and small parts to machine with many different workpiece geometries," Balles explains further. "We have to set up frequently and quickly. It comes down to the highest quality and repeat accuracy every time. And, of course, economy and efficiency. That is why we decided to use the SCHUNK toolholding and workholding modular system. With it, our new machine is perfectly equipped. Flexibility and throughput have increased," assures the machining manager. "With the modular system, we have exactly what we need."

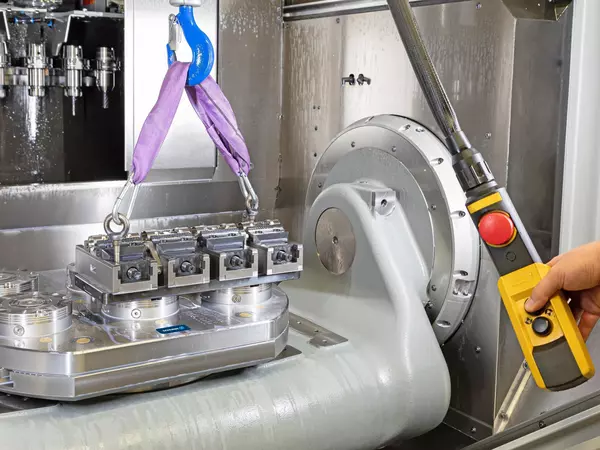

The modular VERO-S quick-change pallet system is the basis and precision interface to the machine table. With it, WIKA realizes universal and precise clamping of a wide range of workpiece geometries. Above all, the VERO-S guarantees efficient, fast set-up. The machining department thus achieves full machine utilization. The extensive VERO-S modular system allows more than 1000 combinations of standard clamping devices for general milling applications and heavy machining on different machines. At WIKA, the clamping station contains six stainless and sealed quick-change pallet modules of the new NSE3 generation; they are equipped with a spring-operated cone lock that automatically locks the change interface of the modules as soon as the clamping pin is lifted out. This prevents chips or dirt from getting into the interface. This ensures a reliable process in the machining sequences as well as the durability of the clamping station. The NSE3 modules are dimensionally stable and can absorb high tilting moments and lateral forces. This results in extremely rigid clamping without vibrations. In addition, the pneumatic NSE3 modules achieve a high pull-down force that is fully maintained even in the event of a pressure drop, and ensures optimal utilization of the machine output.

Different clamping modules of the modular system are used on the VERO-S clamping station. They are ready for any application on the practical SCHUNK set-up trolley. The sturdy welded steel construction with four drawers offers plenty of storage space for any lathe chucks and clamping blocks. Prefabricated plastic clamping bolt holders ensure secure mounting of the toolholding and workholding components. For example, when small, intricately shaped stainless steel components need to be machined, WIKA turns to the KSC 80 small part clamps from SCHUNK. With several modules mounted en bloc, the user can produce several series parts in one set-up – throughput increases. The tool has optimal access to the workpiece from all five sides.

If the production process requires it and precise six – sided machining is on the WIKA agenda, the operator has quickly converted his machine, for example to the slim five – axis clamp KONTEC KSX – C2. The set-up time in conjunction with the VERO-S takes only seconds. SCHUNK has set a new milestone with this fully enclosed and robust clamping block – it offers even more flexibility, even less set-up time and a secure hold in any case. The KSX-C2 jaws can be changed quickly without tools. With a basic clamping stroke of 130 millimeters and reversible jaws for increasing the clamping range, the clamp can be quickly converted to a new range of parts. Many different quick-change jaws are available. Thanks to the active pull-down system, precise six-sided machining is possible on the five-axis machine. Excellent machining results are achieved in terms of plane parallelism and squareness. The outside contour of the KSX-C2, which tapers towards the top, allows good accessibility with standard tools. The operator can continuously adjust the clamping forces via a torque wrench, for example for metered forces for clamping sensitive parts.

For clamping round, cubic or geometrically unshaped workpieces, WIKA uses the flexible ROTA-M flex 2+2 clamping system. The four-jaw manual chuck combines the functions of two-jaw, three-jaw and four-jaw chucks on lathes as well as vises on milling lathes. Due to the coupled jaw pairs, the workpieces are clamped in a centrically compensating manner. A special seal prevents chips and coolant from penetrating into the chuck. In this way, the internal mechanism remains protected, even when cast or forged parts are machined. Thanks to the compensation mechanism, the user can also clamp thin-walled workpieces without deformation – such as sensitive housing parts of WIKA measuring instruments. SCHUNK provides the ROTA-M flex 2+2 in various sizes. A permanent grease supply via a central reservoir ensures constant clamping forces; in this way, the four-jaw manual chuck scores points not only for flexibility and fast set-up, but also for process reliability. Operating safety is not neglected either: an indicator pin marks when the chuck mechanism is about to reach the stroke end position and signals when the workpiece is not properly clamped.

The ROTA-S plus 2.0 manual chuck is also part of WIKA's modular toolholding and workholding. SCHUNK has designed the lathe chuck for a wide variety of clamping tasks as a two-jaw and three-jaw chuck, especially for clamping round workpieces. WIKA uses it, for example, for the series production of measuring cells; mounted as a pair on the VERO-S quick-change pallet system, the set-up effort is minimized and machine performance is improved. WIKA benefits from machining efficiency. The high degree of efficiency of the wedge bar system and the optimized lubrication system provide for clamping in a reliable process with consistently high clamping forces. The developers have pulled out further stops in the design of the ROTA-S plus 2.0: large chuck bore, user-friendly jaw quick-change system, high jaw change repeat accuracy, functional parts hardened and ground on all sides, and visual safety features for maximum operating safety.

A look into the workspace of the C400 makes it clear: WIKA makes optimal use of the possibilities of the SCHUNK modular system. In addition to various clamping systems and lathe chucks for workpiece clamping, toolholders from the international technology leader in toolholding and workholding, gripping technology and automation technology are also used. For example, the TENDO E compact hydraulic expansion toolholder is convincing for milling, drilling, reaming and threading. It scores points with its compact design, permanently strong holding forces and high torque transmission. Run-out accuracy, radial rigidity and vibration damping prevent micro-blowouts and ensure precision machining – the measuring instrument manufacturer WIKA achieves the best workpiece surfaces. The TENDO E compact also scores with its fast set-up – mold changes are performed with micrometer precision in seconds without peripheral equipment.

"We were convinced right from the start that this modular solution from SCHUNK was the right one for us," sums up Michael Balles. Many different workpieces, various clamping systems, several machining centers – WIKA has gained flexibility and can produce with a high vertical range of manufacture. "In order to be able to set up quickly, you need a reliable and robust clamping system in the modular system that can be implemented quickly and easily," states Dr. Alexander Nachtwey, Preproduction Division Manager at WIKA. "Such a system gives us a high level of process reliability in the demanding machining of our high-precision parts. The extensive SCHUNK modular system allows us to make efficient use of all the possibilities and, on top of that, we have created the foundation for future robot-based machine loading."