No matter where or how – fast and secure gripping of workpieces every time. Even if the power happens to fail. Speaking of speed – no one beats our magnetic heroes when it comes to being ready in a hurry. A short pulse of current is all it takes to get the magnetic grippers ready for use.

Uncomplicated, easy to handle and exceptionally strong – it's time to add the invisible force of magnetism to your production!

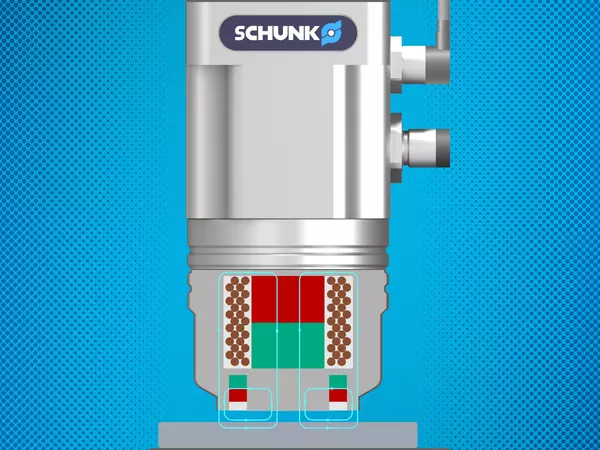

The function of the magnetic gripper is based on the combination of Alnico and neodymium magnets. To activate the system, an electric current pulse is conducted through the coil, which reverses the polarity of the AlNiCo magnet accordingly. The magnetic flux of the AlNiCo magnet passes the neodymium magnet in the deactivated state, and closes the magnetic circuit over the gripper base body made of steel. The workpiece is always held securely – this is ensured by the grippers' mode of operation, which is based on a combination of electric and permanent magnets and reliably maintains the magnetic flux even when deactivated.

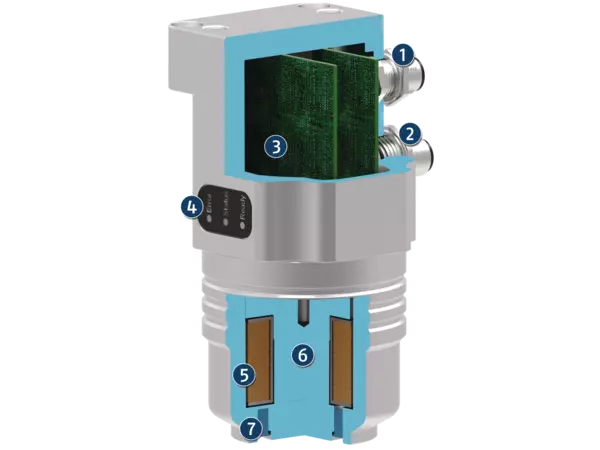

Communication via digital I/O

for power supply

integrated control and power electronics

for pole reversal of the AlNiCo-magnets

surrounded by an electromagnetic coil

lead the magnetic flux via the workpiece

In the SCHUNK Robot Application Center CoLab, we work with you to test your planned application. In this way, we support you in choosing the right magnetic gripper for the job.

Get in touch now with your personal SCHUNK consultant on site so we can discuss and develop your application.