Prozesssicher. Flexibel. Intelligent.

Der intelligente Kleinteilegreifer EGK überzeugt mit seiner Prozesssicherheit. Sein Stirnradgetriebe mit Ritzel-Zahnstangenprinzip gewährleistet eine konstante Greifkraft über die gesamte Fingerlänge und ermöglicht dauerhaftes Nachgreifen. Die integrierte Greifkrafterhaltung verhindert Werkstückverluste und hält die Fingerposition auch bei Not-Aus zuverlässig. Der SoftGrip-Modus ermöglicht zudem das sichere Greifen fragiler Werkstücke ohne Impulskräfte. Damit eignet er sich perfekt für anspruchsvolle Aufgaben in der Laborindustrie und Elektronikfertigung. Der EGK bietet eine große Schnittstellenvielfalt, darunter PROFINET, EtherNet/IP, EtherCAT, IO-Link und Modbus RTU. Die Softwareintegration ist dank mitgelieferter SPS-Funktionsbausteine und Plugins führender Roboterhersteller einfach und erfordert keine zusätzlichen Gateways oder Programmieraufwand.

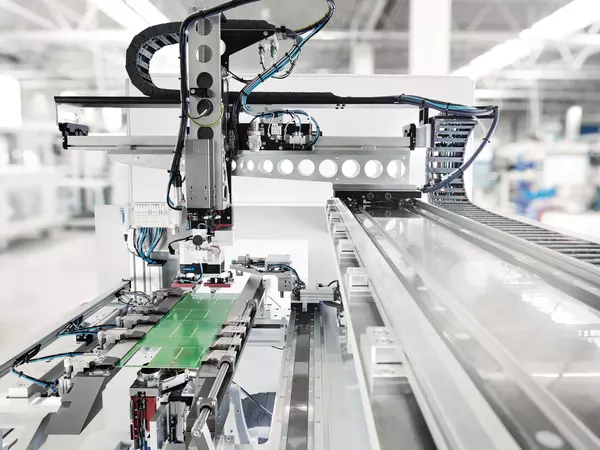

EGK im Einsatz

Mechatronische Greifer

Flexibel und intelligent

Die beiden Greifer EGU und EGK vereinen alle Vorteile des mechatronischen Greifens und bieten durch ihren großen und frei programmierbaren Backenhub bei stufenloser Greifkrafteinstellung eine flexible Werkstückhandhabung.

Vorteile – Ihr Nutzen

- Vielseitig und produktiv

durch den großen und frei programmierbaren Backenhub bei stufenloser Greifkrafteinstellung für eine flexible Werkstückhandhabung - Zuverlässig und feinfühlig

besonders geeignet für die Anforderungen der Laborautomation und Elektronikfertigung durch die abgedichtete Bauweise und leichtgängige Profilschienenführung - Maximal prozesssicher

durch Vermeidung eines Werkstückverlustes dank integrierter Greifkrafterhaltung mit Verlusterkennung - Immer referenziert

sowohl bei Not-Aus als auch bei Stromausfall dank integriertem Absolutwertgeber - 100 % Greifkraft ohne Anfahrweg

bei konstanter Greifkraft über die gesamte Fingerlänge dank integriertem Stirnradgetriebe - Minimaler Integrationsaufwand

durch ein vielfältiges Angebot an Kommunikationsschnittstellen, sowie SPS-Funktionsbausteinen und Roboter Plugins kompatibel mit den führenden Herstellern am Markt

Optionen und spezielle Informationen

- Greifmodi

Es stehen die Greifmodi BasicGrip und SoftGrip zur Verfügung. Mit BasicGrip und SoftGrip ist ein Dauerbetrieb des Motors und damit permanentes Nachgreifen des Werkstücks möglich. Die Greifgeschwindigkeit wird mit BasicGrip automatisch zur Greifkrafteinstellung optimiert. Mit SoftGrip können bruchempfindliche Werkstücke besonders schonend gegriffen werden, indem die Impulskräfte beim Auftreffen auf das Werkstück auf ein Minimum reduziert werden. - Greifkrafterhaltung

Durch eine Kombination aus elektrischer Haltebremse und der Vorspannung eines elastischen Elements kann bei einer Not-Aus-Situation oder einem Spannungsabfall eine Greifkraft von über 75 % der ursprünglich aufgebrachten Greifkraft zuverlässig erhalten werden. Wird die Greifkraft- und Positionserhaltung präventiv aktiviert, so können 90 % der ursprünglich aufgebrachten Greifkraft erhalten werden. Der Nachlaufweg der Greiferfinger beim Entfernen des Werkstücks beträgt wenige Millimeter und ist abhängig von der erzeugten Greifkraft. Optional sind auch Varianten ohne Greifkrafterhaltung verfügbar. - Abdichtung

Der Greifer verfügt standardmäßig über einen erhöhten Schutz gegen das Eindringen von Stäuben oder Flüssigkeiten. Der IP-Schutz der Elektronik ist nur dann gegeben, wenn die Steckverbinder ordnungsgemäß montiert wurden. Das Getriebe des Greifers ist zusätzlich durch eine Abdichtung an der Hauptwelle geschützt. - Schnittstelle der Grundbacken

Bei Verwendung der Zwischenbacke entspricht die Schnittstelle der Grundbacken der des Universalgreifers PGN-plus-P. Somit kann das umfangreiche Fingerzubehör des PGN-plus-P unter Berücksichtigung der Störkonturen und der geltenden Einsatzgrenzen für diesen Greifer genutzt werden. - Standardmäßig mit lebensmittelkonformer Schmierung

als Einstiegslösung in MedTech, Lab Automation, Pharma und der Lebensmittelindustrie. Die Anforderungen der EN 1672-2:2020 werden nicht vollumfänglich erfüllt.