EGK

Process-reliable. Flexible. Intelligent.

The intelligent EGK gripper for small components has impressive process reliability. Its spur gear with pinion/rack principle guarantees a constant gripping force over the entire finger length and allows permanent re-gripping. The integrated gripping force maintenance prevents workpiece losses and holds the finger position even in the event of an emergency stop. The SoftGrip mode also enables fragile workpieces to be gripped securely without impulse forces. This makes it perfect for demanding tasks in the laboratory industry and in the production of electronics. The EGK offers a wide range of interfaces, including PROFINET, EtherNet/IP, EtherCAT, IO-Link and Modbus RTU. Software integration is simple due to the supplied PLC function modules and plug-ins for leading robot manufacturers and does not require any additional gateways or programming workload.

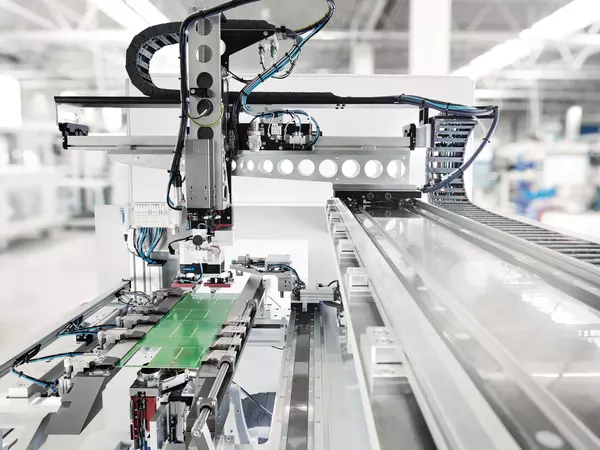

EGK in use

Mechatronic grippers

Flexible and intelligent

The two grippers EGU and EGK combine all the advantages of mechatronic gripping and offer flexible workpiece handling due to their long and freely programmable jaw stroke with infinitely variable gripping force adjustment.

Advantages – Your benefits

- Versatile and productive

due to the long and freely programmable jaw stroke with continuous gripping force adjustment for flexible workpiece handling - Reliable and sensitive

particularly suitable for the requirements of laboratory automation and electronics production due to the sealed design and smooth-running profiled rail guide - Maximum process reliability

by avoiding workpiece loss due to integrated gripping force maintenance with loss detection - Always referenced

both in the event of an emergency stop and a power failure due to integrated absolute encoder - 100% gripping force without start-up distance

with constant gripping force over the entire finger length due to integrated spur gear - Minimal integration effort

compatible with the leading manufacturers on the market due to a wide range of communication interfaces, as well as PLC function blocks and robot plug-ins

Options and special information

- Gripping modes

The BasicGrip and SoftGrip gripping modes are available. With BasicGrip and SoftGrip, continuous operation of the motor and thus permanent re-gripping of the workpiece is possible. The gripping speed is automatically optimized to the gripping force setting with BasicGrip. With SoftGrip, fracture-sensitive workpieces can be gripped particularly gently by reducing the impulse forces to a minimum when they hit the workpiece. - Maintenance of gripping force

In the event of an emergency stop or a voltage drop, more than 75% of the originally applied gripping force can be reliably maintained due to a combination of an electric holding brake and the initial tension of the elastic element. If the gripping force and position maintenance is activated preventatively, 90% of the originally applied gripping force can be maintained. Overrun of the gripper fingers when removing the workpiece is a few millimeters and depends on the gripping force generated. Variants without gripping force maintenance are also available as an option. - Seal

The gripper has increased protection against the ingress of dust or liquids by default. The IP protection of the electronics is only given if the plug connectors have been mounted properly. The gearbox of the gripper is additionally protected by a seal on the main shaft. - Interface of the base jaws

When using the intermediate jaw, the interface of the base jaws corresponds to that of the universal gripper PGN-plus-P. This means that the extensive range of finger accessories for the PGN-plus-P can also be used for this gripper, taking into account the interfering contours, and the application limits that apply. - With food-compliant lubrication as standard

as an easy solution for entry into medical technology, lab automation, the pharmaceutical and food industry. The requirements of EN 1672-2:2020 are not fully met.