The family-owned company is pushing forward digitalization both with its solutions for customers and at a higher level. For example, SCHUNK has long been involved in the management of the Industry 4.0 platform, the network of German business associations that drives the German government's high-tech strategy. This is one way that the company is helping to shape the digital transformation of the industry and is launching concepts on key digital topics. This demonstrates that SCHUNK is already implementing the central theme of this year's Hannover Messe, "Industrial Transformation – Making the Difference". CEO Henrik A. Schunk is also involved in the Manufacturing-X digitalization initiative. This initiative aims to create a sovereign, federated data space for the digitally connected industry and that makes value chains more sustainable, transparent and resilient. After all, trust and control over their own data is crucial for companies on their way to a successful digital future.

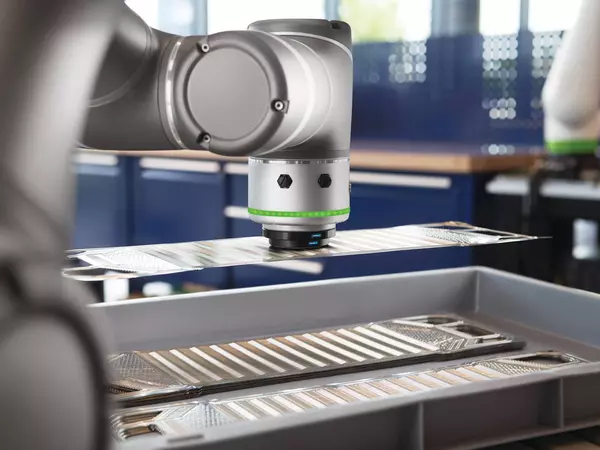

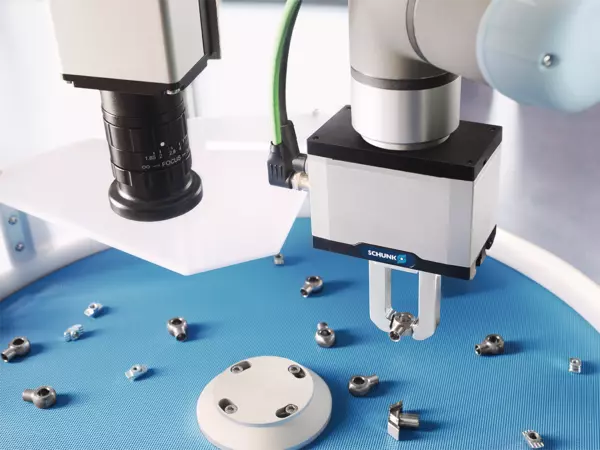

SCHUNK demonstrates on site exactly how digital solutions can lead to more efficiency and lower resource consumption using three innovative examples. The bio-inspired technology ADHESO grips delicate or difficult-to-handle parts gently, without leaving residues and, most importantly, without any energy at all, by using adhesive force. The environmentally friendly technology was awarded the German Innovation Prize for Climate and Environment (IKU) in 2022. The iTENDO² smart toolholder transmits data in real time, thereby safeguarding machining processes where maximum precision is required. The solution, which won the German Innovation Award 2022, provides transparency and traceability and can therefore also reduce rejects. Thanks to an AI developed by SCHUNK, the 2D Grasping Kit makes gripping of individual objects that are randomly arranged on a level, child's play. The complete package of hardware, software and service requires no prior knowledge of programming or image recognition. Join us for exchanging ideas with us on these innovations. We look forward to making the difference: together with you!