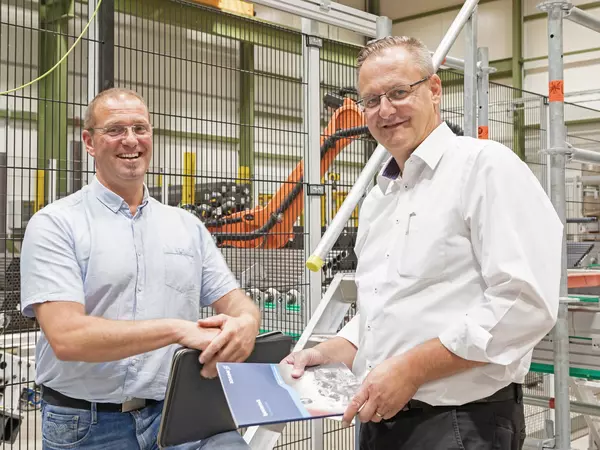

"It's all built in-house," says Jörg Brauhardt, Head of Design at MJ-Gerüst, pointing to the impressive production facility in which scaffolding stanchions are manufactured. In the interlinked production line, which takes up more than half the hall, the input stock is cut to length, deburred, marked, formed, perforated, annealed, and finally removed ready for transportation. The individual processes take place in several processing cells with more than ten robots. Driven prismatic rollers transport the long stock from station to station in the separate cells. "This system processes tubes up to 2,500 millimeters in length, made from 48-3 steel tube," explains Brauhardt. "Our design team had an initial system of a similar type as a model for the concept that was created here at the desk. This first system processes material up to four meters in length, and urgently needed support because it was already operating in three shifts and the volume was continuing to grow. "We had already installed PGN-plus grippers here," says Brauhardt. "We have been familiar with SCHUNK products for years and have never had any problems with them, which is why the new system is also equipped with SCHUNK modules."

Almost 120 PGN-plus-P grippers are in action, as well as around 25 EGM magnetic grippers and several lathe chucks. "We attach great importance to quality, robustness, stability, and durability," states Jörg Brauhardt. "The repeat accuracy of the gripper is also very important because of the long components and the bowing. All components in the system must meet demanding requirements, because we need a reliable overall process," emphasizes Brauhardt. With 27 years of experience in construction, he knows what he is talking about and what is needed to automate the specific task. "This is a rough, tough business, and it's important for safety, so we need high quality here. Everything has to fit, it has to work and it has to last."

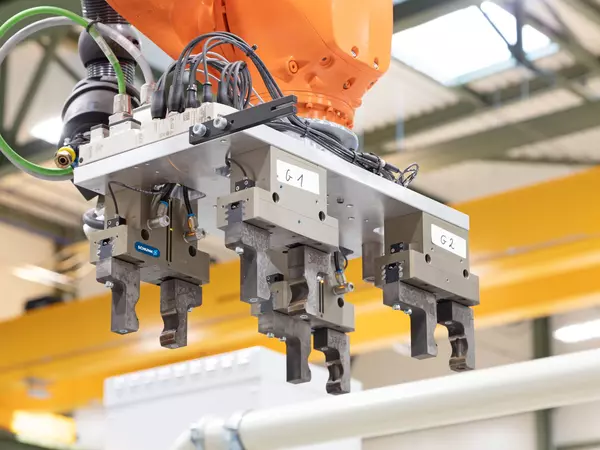

Especially with these harsh sequences in metalworking. A machine failure means the entire production line grinds to a halt, because all stations are interconnected. "We can't allow that to happen," emphasizes Jörg Brauhardt. The input stock arrives in bundles by crane or forklift and is placed in the first station for separation. Each individual tube is first automatically measured for length. It is then transferred by two robots, each with several PGN-plus-P grippers, to a pusher on which a ROTA TP 200 three-jaw chuck from SCHUNK is installed. The pusher moves with the tube into a laser cutting cell; while the laser head positions itself, the tube is held in place and then rotated endlessly until the ends are cut off on the left and right. The laser cell stops rotating when cutting is complete. This is followed by the deburring station, from which several EGM magnetic grippers from SCHUNK pick up the tubes. "After the cutting station, the tubes are deburred, initially picked up in packs of two, transferred and fed on in bundles of three," explains Brauhardt. "The magnetic grippers with an adapted half-shell grip the tubes very tightly and close together. This avoids rattling and clattering at this point and protects the material."

Each tube is separated again for the next station – marking with a serial number and article number using needle scribing. Each individual tube is marked, which is important for the manufacturer during welding and storage. The marking is still visible after galvanizing and ensures the permanent traceability of the components.

Finally, one end of the tube is tapered by cold forming, which thickens the material and results in a highly stable tube connection. The tubes are now measured again in relation to the zero point, so that they can be safely gripped by the robot for the next and final process: six tubes in a bundle are inserted into the final laser cell, where the tubes are perforated.

Six finished tubes leave the line every 60 seconds. SCHUNK components do their job at every processing and handling station – reliably and in large quantities. The PGN-plus-P universal gripper is used in the system in both sizes 100 and 125. The most proven and versatile parallel gripper on the market offers an impressively high load capacity thanks to the improved multi-tooth guidance and maintenance-free, reliable operation thanks to permanent lubrication. "We have adapted the gripper jaws specifically to the tube geometry at each station, depending on the handling situation," explains Jörg Brauhardt. "This ensures that the long stock is are securely gripped at every point. Once this gripper has been installed, you don't need to think about it any longer," says the Head of Design. With its powerful features, the PGN-plus-P is in a class of its own.

The EGM electro-permanent magnetic gripper for the energy-efficient handling of ferromagnetic workpieces performs to its strengths in this system. With its low weight and high dynamics, it handles the long stock reliably. The workpiece accessibility without interfering contours enables handling with close tolerances but without damage. Electricity is only required for magnetization and demagnetization "The ROTA TP 200 power lathe chuck is also just what is called for here," says the Head of Design. The integrated clamping cylinder means that the maximum size of through-hole is possible, making it ideal for machining tubes. The chuck can also be actuated when stationary. Pneumatic power lathe chucks from SCHUNK are an appropriate alternative if the chuck is not to be actuated manually or via hydraulics.

The cycle time-optimized, interlinked system is designed for the future, assures Brauhardt, visibly satisfied with the result. The gripping and clamping modules do what they are supposed to do. "This is top quality, nothing breaks." It proved possible to implement the best solution thanks to close cooperation and intensive discussions between the user and SCHUNK. Once again, the customer benefits from the fact that SCHUNK can provide suitable components for the respective processes thanks to its extensive automation expertise. Reliable and smooth sequences ensure that productivity is increased and waste is avoided. "The combination of clamping technology and automation in this system is certainly unique," summarizes Jörg Brauhardt. "This is a good example of authentic German mechanical engineering."