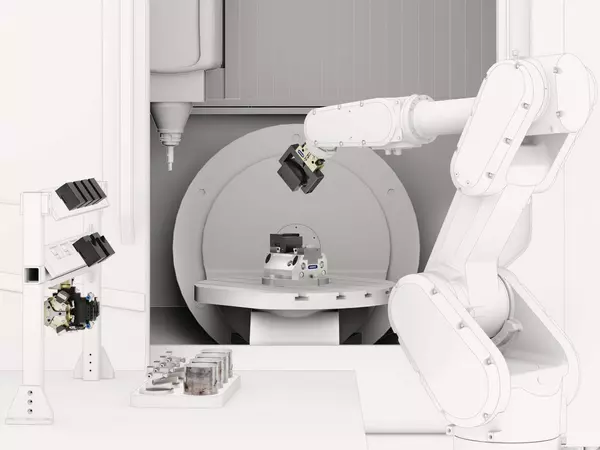

In many industrialized countries, the labor market can no longer meet the demand for skilled workers. Many industries are also facing competitive pressures that demand more productive manufacturing operations. Both trends mean that automated processes are becoming more and more important and that companies will have to open up to them sooner or later. Application specialist SCHUNK has developed a suitable module to expand the possibilities of autonomous machining processes. With the new jaw quick-change system BWA, chuck jaws of the TANDEM clamping force blocks can now be changed manually or fully automatically via a robot. In future, the system will be available as standard for the pneumatic and hydraulic 2- and 3-jaw clamping force blocks in sizes 100, 140, 160 and 250.

Short response times for changing batch sizes

The quick-change jaws included in the clamping devices can be changed automatically in seconds without the use of any tools. As an experienced full-range supplier, SCHUNK also offers the matching PGN-plus-P pneumatic parallel gripper for automated placement for this purpose. The gripper fingers are equipped with special, spring-loaded holding pieces. This allows the top jaws to be automatically unlocked, picked up and reinserted in a positive fit. The application can thus be flexibly adapted to new clamping tasks at any time. The jaw quick-change system TANDEM enables five times faster manual changing compared to conventional jaw changes too.

Monitoring integrated by default

In terms of automation, the monitoring options integrated as standard in the clamping devices are particularly future-compatible. As well as patented dynamic pressure monitoring for the basic jaw positions "open" and "closed", monitoring of compressed air transfer to the chuck jaw already comes as integrated. In this way, a workpiece contact control or cleaning of the clamping surfaces can be done by the customer.

All TANDEM clamping force blocks have one thing in common: They offer consistently high clamping forces with a compact design and optimal accessibility in 5-sided machining, even in confined spaces. Increased competitiveness in all industries through maximum flexibility and short response times In addition to the clamping force block and chuck jaws, the handling components on the robot are also essential for an automated process sequence. With its extensive perfectly matched portfolio of clamping technology, gripping technology and automation components, SCHUNK offers application solutions from one source.