The laser has established itself as an accurate, clean, and efficient tool in many fields. With the new SAL-1300 laser depaneling system, SCHUNK is taking full advantage of these benefits. For the first time, the innovative speedLAS® technology developed by SCHUNK for the SAL-1300 is making it possible to control the laser using a special scanner in such a way that its movements are able to superimpose those of the axes. speedLAS® technology ensures that the light from the laser is always aligned at a perpendicular angle to the workpiece, regardless of the axis movement. This ensures uniform energy input and therefore also precision cuts right into the edge areas. Compared to previous laser applications, the SAL-1300 also delivers up to an 80% faster processing speed.

The SAL-1300 works independent of the laser source – this means that it is possible to use any wavelength. It also allows the best laser source to be chosen for every material. To this end, SCHUNK relies on comprehensive process support in collaboration with its cooperation partner Dr. Bohrer Lasertech GmbH. The basis for selecting the best possible laser source for each requirement lies in experience and a precise analysis of the materials to be processed using a scanning electron microscope.

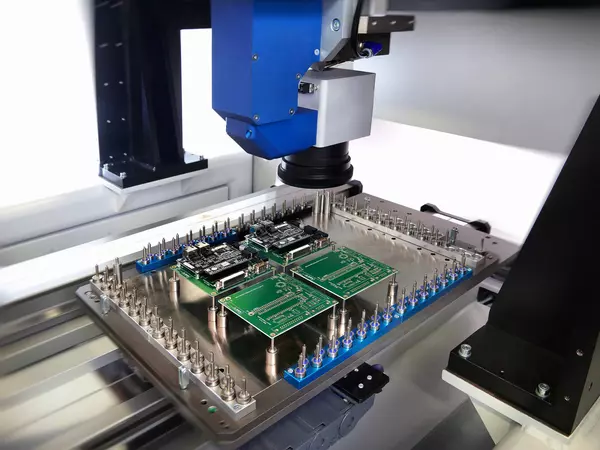

The compact SAL-1300 is similar in size to the well-known SAR series systems. Nothing has changed in the proven operating concept either. Existing workpiece holders from SAR depaneling machines can also be used with the SAL-1300. Completely new machining possibilities have been opened up, however, due to the option of supplementing the system with a milling gantry. By combining laser processing and milling technology on a single machine, workpieces with flex components, for example, can be processed quickly and with maximum precision without any manual intervention. The optional milling gantry can be retrofitted.