EGU

Robust. Flexibel. Intelligent.

Der Universalgreifer EGU von SCHUNK ist ideal für flexible Fertigungsabläufe ab Losgröße 1, auch in rauen Umgebungen. Er ist frei vernetzbar und einfach in variantenreiche Fertigungsprozesse integrierbar. Mit integrierter Greifkrafterhaltung und StrongGrip-Modus für erhöhte Greifkraft ist er ein zuverlässiger Allrounder für vielfältige Handhabungsaufgaben. Der EGU bietet eine große Schnittstellenvielfalt, darunter PROFINET, EtherNet/IP, EtherCAT, IO-Link und Modbus RTU. Die Softwareintegration ist dank mitgelieferter SPS-Funktionsbausteine und Plugins führender Roboterhersteller einfach und erfordert keine zusätzlichen Gateways oder Programmieraufwand.

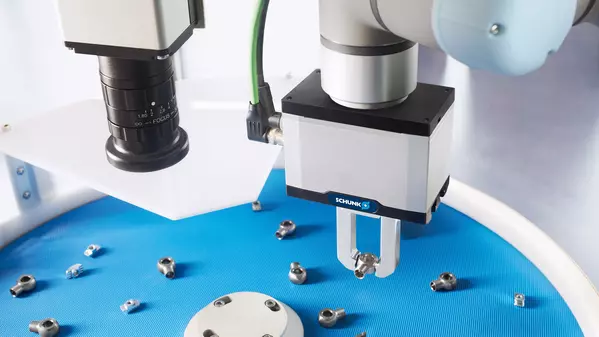

EGU im Einsatz

Mechatronische Greifer

Flexibel und intelligent

Die beiden Greifer EGU und EGK vereinen alle Vorteile des mechatronischen Greifens und bieten durch ihren großen und frei programmierbaren Backenhub bei stufenloser Greifkrafteinstellung eine flexible Werkstückhandhabung.

Vorteile – Ihr Nutzen

- Vielseitig und produktiv

durch den großen und frei programmierbaren Backenhub bei stufenloser Greifkrafteinstellung für eine flexible Werkstückhandhabung - Robust und zuverlässig

mit abgedichteter Bauweise und bewährter Gleitführung besonders geeignet für die rauen Umgebungsbedingungen der Maschinenbeladung - Maximal prozesssicher

durch Vermeidung eines Werkstückverlustes dank integrierter Greifkrafterhaltung mit Verlusterkennung - Immer referenziert

sowohl bei Not-Aus als auch bei Stromausfall dank integriertem Absolutwertgeber - 100 % Greifkraft ohne Anfahrweg

bei nahezu konstanter Greifkraft über die gesamte Fingerlänge dank integriertem Stirnradgetriebe - Minimaler Integrationsaufwand

durch ein vielfältiges Angebot an Kommunikationsschnittstellen, sowie SPS-Funktionsbausteinen und Roboter-Plugins kompatibel mit den führenden Herstellern am Markt

Optionen und spezielle Informationen

- Greifmodi

Es stehen die Greifmodi BasicGrip und StrongGrip zur Verfügung. Mit BasicGrip ist ein Dauerbetrieb des Motors und damit ein permanentes Nachgreifen des Werkstücks möglich. Die Greifgeschwindigkeit wird automatisch zur Greifkrafteinstellung optimiert. Mit StrongGrip wird die maximale Greifkraft erzeugt und anschließend durch die Greifkrafterhaltung gespeichert. Permanentes Nachgreifen ist innerhalb eines einstellbaren Zeitfensters möglich. Zusätzlich müssen im StrongGrip-Modus definierte Pausenzeiten und maximale Umgebungstemperaturen berücksichtigt werden. Weitere Details können der Betriebsanleitung entnommen werden. - Greifkrafterhaltung

Durch eine Kombination aus elektrischer Haltebremse und der Vorspannung eines elastischen Elements kann bei einer Not-Aus-Situation oder einem Spannungsabfall eine Greifkraft von über 80 % der ursprünglich aufgebrachten Greifkraft zuverlässig erhalten werden. Wird die Greifkraft- und Positionserhaltung präventiv aktiviert, so können 100 % der ursprünglich aufgebrachten Greifkraft erhalten werden. Der Nachlaufweg der Greiferfinger beim Entfernen des Werkstücks beträgt wenige Millimeter und ist abhängig von der erzeugten Greifkraft. Optional sind auch Varianten ohne Greifkrafterhaltung verfügbar. - Abdichtung

Der Greifer verfügt standardmäßig über einen erhöhten Schutz gegen das Eindringen von Stäuben oder Flüssigkeiten. Der IP-Schutz der Elektronik ist nur dann gegeben, wenn die Steckverbinder ordnungsgemäß montiert wurden. Das Getriebe des Greifers ist zusätzlich durch eine Abdichtung an der Hauptwelle geschützt. - Schnittstelle der Grundbacken

Bei Verwendung der Zwischenbacke entspricht die Schnittstelle der Grundbacken der des Universalgreifers PGN-plus-P. Somit kann das umfangreiche Fingerzubehör des PGN-plus-P unter Berücksichtigung der Störkonturen und der geltenden Einsatzgrenzen für diesen Greifer genutzt werden.