PRH 060-030-PB-65

ID 306882

- Relação de engrenagens: 30:1

- Torque: 1.8 Nm

- Corrente nominal: 3.7 A

- Fonte de energia: 24 V

- Classe de proteção IP: 65

Technical details

| Pico de torque [Nm] | 4.5 |

|---|---|

| Torque nominal [Nm] | 1.8 |

| Velocidade nominal [1/min] | 117.0 |

| Velocidade de rotação máx. [1/min] | 200.0 |

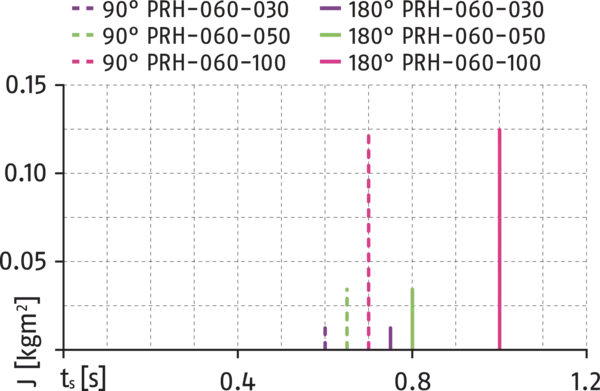

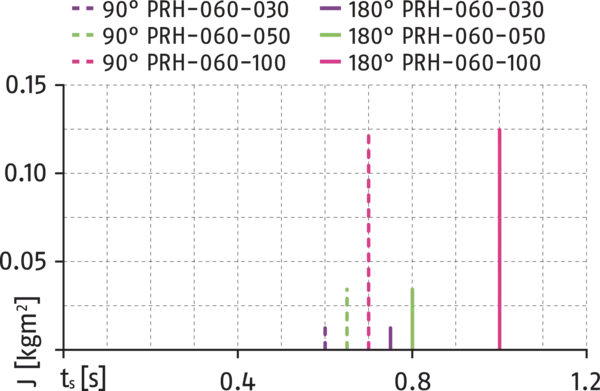

| Momento de inércia de massa máx. admissível [kgm²] | 0.012 |

| Precisão de repetição [°] | 0.004 |

| Desvio axial [mm] | 0.01 |

| Precisão de concentricidade [mm] | 0.01 |

| Transmissão | 30:1 |

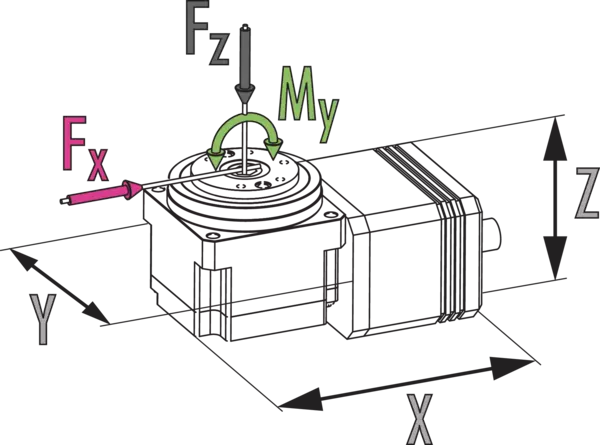

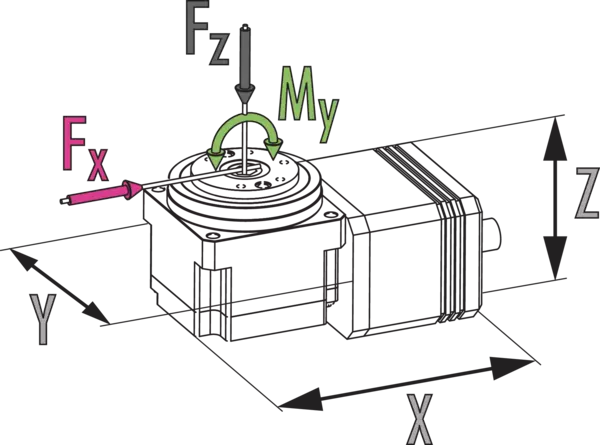

| Momento My máx. [Nm] | 40.0 |

| Força Fx máx. [N] | 300.0 |

| Força Fz máx. [N] | 300.0 |

| Peso [kg] | 0.97 |

| Min. temperatura ambiente [°C] | 0.0 |

| Máx. temperatura ambiente [°C] | 40.0 |

| Classe de proteção IP | 65 |

| Comprimento X [mm] | 127.5 |

| Largura Y [mm] | 67.0 |

| Altura Z [mm] | 64.5 |

| Voltagem nominal [V] | 24.0 |

| Corrente nominal [A] | 3.7 |

| Máx. atual [A] | 7.8 |

| Eletrônica de controle | integrado |

| Fonte de energia [V] | 24.0 |

| Sistema codificador | Codificador (incremental) |

| Interface | PROFIBUS, USB (parametrização) |

| Interface PROFIBUS [Mbit/s] | 12.0 |

| Interface USB | Dispositivo |

| Número de entradas digitais | 4.0 |

| Número de saídas digitais | 0.0 |

Dimensions and maximum loads

Diagrama de tempo de giro

Dimensions and maximum loads

Moments and forces may occur simultaneously.

Diagrama de tempo de giro

- X-axis:

- Swiveling time

- Y-axis:

- Inertia

- X-axis top:

- Cycles per hour

General notes about the series

Swiveling times

are purely the times of the module to rotate from rest position to rest position. Relay switching times or PLC reaction times are not included in the above times and must be taken into consideration when determining cycle times. Load-dependent rest periods may have to be included in the cycle time.

Repeat accuracy

Is defined as the spread of the target position after 100 consecutive positioning cycles.

Nominal currents

can be permanently actuated. With regard to all the currents which are ranging above the nominal current up to the maximum current, the notes of the individual product documentation has to be respected.

Peak torque

The peak torques serve as short-term drive reserves when accelerating and delaying.

Housing material

Aluminum alloy

Actuation

servo-electric, via brushless DC servomotor

Operating principle

Harmonic drive® gear driven directly via brushless DC servomotor

Scope of delivery

QR slip for downloading the commissioning software, safety information (product-specific instructions available online), functional module for control via Siemens S7.

Warranty

24 months

Service life characteristics

on request