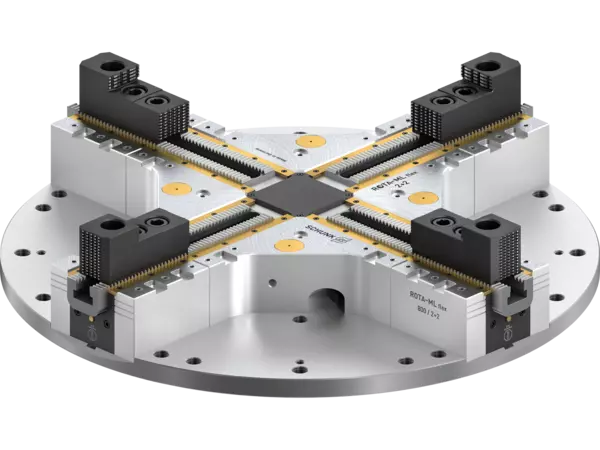

With the centrically compensating ROTA-ML flex 2+2, SCHUNK has had a low-maintenance manual lathe chuck in its portfolio since 2020. It allows almost all workpiece geometries – whether round, cubic or geometrically unshaped – to be precisely and efficiently clamped on mill/turn centers. Its patented drive concept has a particularly large compensation stroke with 12 mm per jaw. With the revision, SCHUNK has now significantly improved the manual lathe chuck.

With a structural facelift starting from the size 500 millimeter in diameter, the toolholding and workholding expert reduced the chuck height by up to 30 percent. This also reduces the chuck weight by up to 40 percent. The lower mass allows higher table rotation speeds, but also process-reliable machining of even larger and heavier workpieces. This increases the variety of applications with only one chuck as well as the efficiency in machining processes.

The revised base plate of the chuck also provides more flexibility. The lathe chucks can be set up quickly and easily on almost any machine table.

The lathe chuck continues to feature the special seals on the guiding rails. They prevent grease from being washed out and reduce the gradual loss of the clamping force. This ensures precise functioning of the lathe chuck, even if low clamping forces are applied. A patented sealing concept protects the drive kinematics against dust and chips thereby enhancing process reliability and extending maintenance intervals. Moreover, an indicator pin at each jaw signals the optimal clamping range for secure workpiece clamping.

SCHUNK offers the flexible manual lathe chuck in eight sizes ranging from a diameter of 260 to 1,200 mm.