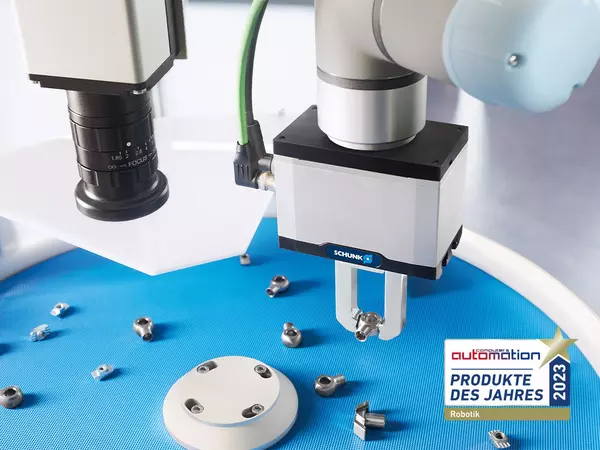

SCHUNK the automation specialist takes the first place with the 2D grasping kit of the competition "Product of the Year 2023" of the German trade magazine Computer & Automation. The innovative solution for handling individual objects that are randomly arranged on one plane, convinced the readers in the category robotics. The kit combines intelligent object recognition and flexible gripping with intuitive handling, and is adaptable to specific customer requirements. At the core of the intelligent system is the AI software developed by SCHUNK that is pre-installed on the SCHUNK-own industrial PC (SVC). This fully coordinated package of hardware, software and service stems from one source and can be used for all robots.

Removal of individual and randomly arranged parts from a feeding belt, tray or supply table is a common process in countless production processes. In many industries, various parts are separated, further processed, or fed to a machine. This can be done manually or automated – automated handling is done by using robot, gripper and vision system. However, it is demanding and requires experience in the filed of image processing, illumination and process technology. With the 2D grasping kit a complete solution is available now, which facilitates the entry into automated object handling much easier. Users can easily integrate the plug-and-play-capable, vision-based system and implement automation directly. This supports companies that are still at the beginning of automating their manufacturing processes. Expert knowledge in programming or image processing is not required. Users benefit from the easy integration and full compatibility of all components. The system allows you to achieve greater efficiency, productivity and process reliability while significantly simplifying part handling.