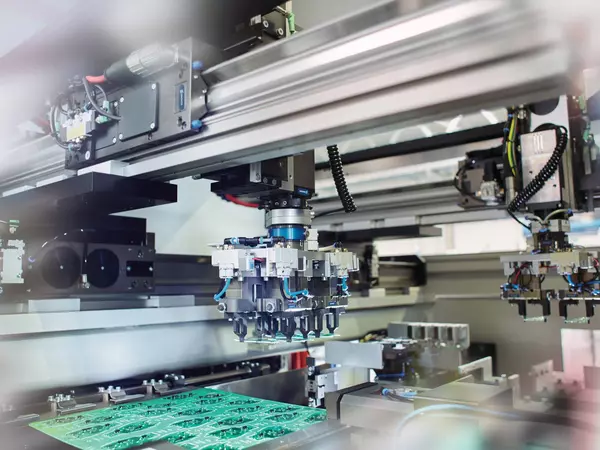

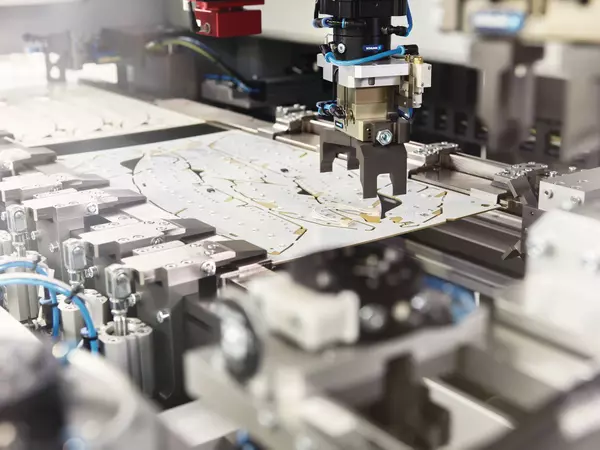

For medium to large batch sizes and low to medium product variance: The SCHUNK inline depaneling machine of the ILR series in combination with a gripper change system ensures maximum flexibility and minimum set-up times. With the specially developed high-speed panel feed and the use of highly dynamic drives with path control for separation and printed circuit board handling, maximum throughput is achieved. The simple and weight-optimized design of the multi panel gripper significantly reduces the tool costs.

The project managers at SCHUNK are specialists in the depaneling process, enabling them to ensure our machines are optimally integrated into customer processes. Individually customer-defined processes can be easily and efficiently integrated into the cells. With reliability, reliable on-time deliveries for all project phases, and transparent communication our team creates the basis for a trustworthy collaboration.

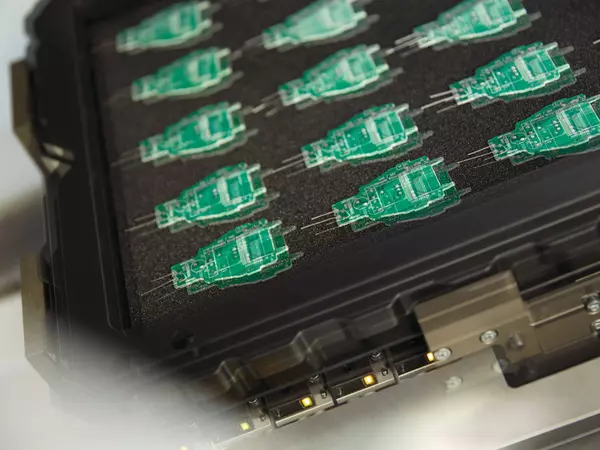

The automatic exchange of gripper fingers allows fast and simple product change without the need for additional costly grippers. Up to 24 gripper fingers can be inserted in the storage rack. Therefore 276 finger combinations are available. The machine is permanently equipped with all products.

Light grippers for printed circuit board handling allow short cycle times and maximum flexibility.

During the visual inspection, the printed circuit board is examined for deviations from the layout. The contours on the surface of the printed circuit board are compared to the CAD data or the tolerance windows provided for even the smallest deviations.