BSWS-R-PGZN-plus

Funzionamento

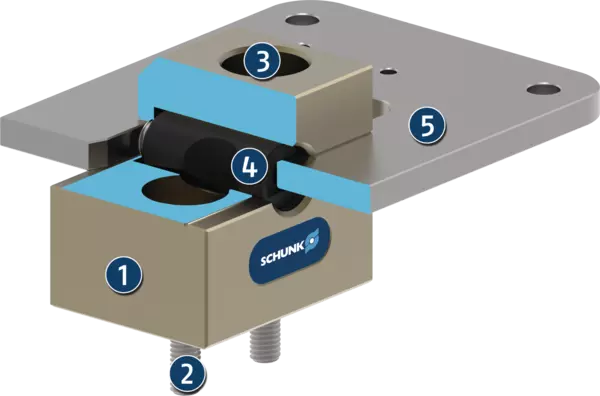

剖视图

剖视图

剖视图

- 1

-

BSWS-BR 基爪快换系统

- 2

-

工件专用机械手手指的固定

- 3

-

连接销 BSWS-AR 用于固定在机械手基爪上

- 4

-

弹簧预装锁销

剖视图

BSWS-R 由一个底座和两个连接销钉组成,前者紧固在要更换的工件专用手指上,后者则固定在机械手的基爪上。适形锁定机构保证快速更换机械手手指。通过收回储存站来更换机械手,从而激活锁定机构。因此,当向上伸出时,机械手手指仍留在储存站中。每个机械手夹爪均需要两个连接销(= 1 套 BSWS-AR)、一个基座 (BSWS-BR) 和一个储存站 (BSWS-SR)。

- 1

-

BSWS-BR 基爪快换系统

- 2

-

工件专用机械手手指的固定

- 3

-

连接销 BSWS-AR 用于固定在机械手基爪上

- 4

-

弹簧预装锁销

- 5

-

储存站 BSWS-SR 用于存放工件专用机械手手指,包括基爪快换系统 BSWS-BR

Automatic jaw quick-change system BSWS-BR/BSWS-AR

BSWS-BR in locked status without adapter pin BSWS-AR

BSWS-BR in unlocked status in the deposit station BSWS-SR without adapter pin BSWS-AR

BSWS-BR in unlocked status in the deposit station BSWS-SR with adapter pin BSWS-AR

BSWS-BR in locked status with adapter pin BSWS-AR

Deposit station BSWS-SR

Gripper finger change in 3 steps

Induktive Abfrage der Anwesenheit des BSWS-R im BSWS-SR

RFID-Datenträger

Automatic jaw quick-change system BSWS-BR/BSWS-AR

With the combination of basic BSWS-BR (firmly screwed onto the workpiece-specific gripper finger) and adapter pin BSWS-AR (firmly screwed onto the base jaws of the gripper), an automatic change of the gripper jaws is possible.

- 1

-

BSWS-AR jaw quick-change adapter

- 2

-

Basic jaw quick-change system BSWS-BR

- 3

-

Workpiece-specific gripper fingers

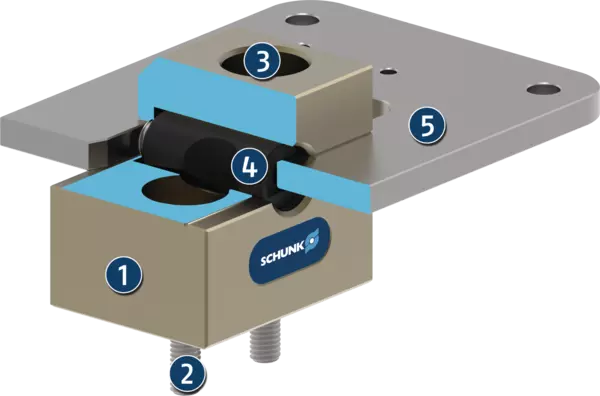

BSWS-BR in locked status without adapter pin BSWS-AR

The locking pin is spring-preloaded and therefore in a locked status as standard. The gripper finger must be retracted into the deposit station BSWS-SR in order to change it.

- 1

-

Basic jaw quick-change system BSWS-BR

- 2

-

Fitting for fastening of the workpiece-specific gripper finger

- 3

-

Mounting bore for jaw quick-change adapter BSWS-AR

- 4

-

Spring preloaded locking pin

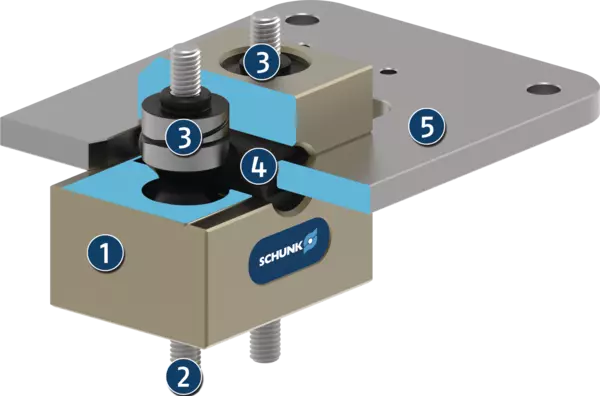

BSWS-BR in unlocked status in the deposit station BSWS-SR without adapter pin BSWS-AR

When the basic BSWS-BR is moved into the storage station BSWS-SR, the locking pin is pressed against a spring and thus unlocked. It is now possible to retract/extend the adapter pin BSWS-AR into the basic BSWS-BR.

- 1

-

Basic jaw quick-change system BSWS-BR

- 2

-

Fitting for fastening of the workpiece-specific gripper finger

- 3

-

Mounting bore for jaw quick-change adapter BSWS-AR

- 4

-

Spring preloaded locking pin

- 5

-

Deposit station BSWS-SR

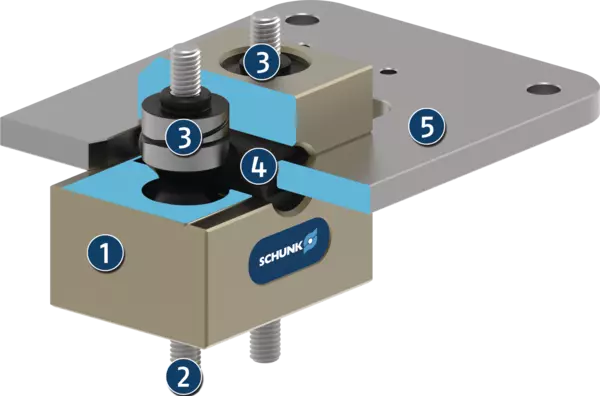

BSWS-BR in unlocked status in the deposit station BSWS-SR with adapter pin BSWS-AR

To lock the adapter pins BSWS-AR in the basic BSWS-BR, it is only necessary to move out of the deposit station BSWS-SR.

- 1

-

Basic jaw quick-change system BSWS-BR

- 2

-

Fitting for fastening of the workpiece-specific gripper finger

- 3

-

BSWS-AR jaw quick-change adapter

- 4

-

Spring preloaded locking pin

- 5

-

Deposit station BSWS-SR

BSWS-BR in locked status with adapter pin BSWS-AR

The spring-preloaded locking pin is pressed back into the locked status by the installed spring, creating a positive fit with the two adapter pins BSWS-AR. The spring force then prevents the gripper fingers from falling out again.

- 1

-

Basic jaw quick-change system BSWS-BR

- 2

-

Fitting for fastening of the workpiece-specific gripper finger

- 3

-

BSWS-AR jaw quick-change adapter

- 4

-

Spring preloaded locking pin

Deposit station BSWS-SR

The deposit stations in sizes 50 - 100 are also suitable for operation with cobots without overloading them thanks to their integrated elastic mounting. From size 125 onwards, the deposit stations are configured without elastic mounting.

- 1

-

Size 50 - 100

- 2

-

Sizes 125 – 300

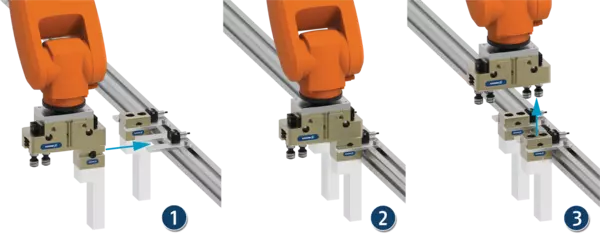

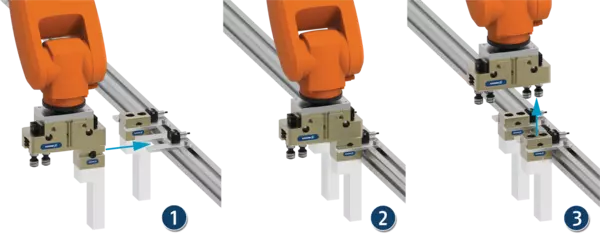

Gripper finger change in 3 steps

After pre-positioning, the actual change takes place by moving into the deposit station. During retraction, the locking mechanism is actuated. As a result, the gripper finger remains in the deposit station when it is extended upwards.

- 1

-

Vorpositionieren

- 2

-

Einfahren in Ablagestation und Entriegeln der Backenschnellwechselbasis BSWS-BR

- 3

-

Ausfahren und ablegen des werkstückspezifischen Greiferfingers

Induktive Abfrage der Anwesenheit des BSWS-R im BSWS-SR

Zur Abfrage der Anwesenheit der Basis BSWS-BR in der Ablagestation BSWS-SR, kann diese mit einem induktiven Näherungsschalter versehen werden.

RFID-Datenträger

Die Basis BSWS-BR ist zur Montag eine RFID-Datenträgers vorbereitet. Die Montage eines RFID-Datenträgers nach DIN 69873 ermöglicht die Codierung der werkstückspezifischen Greiferfinger.

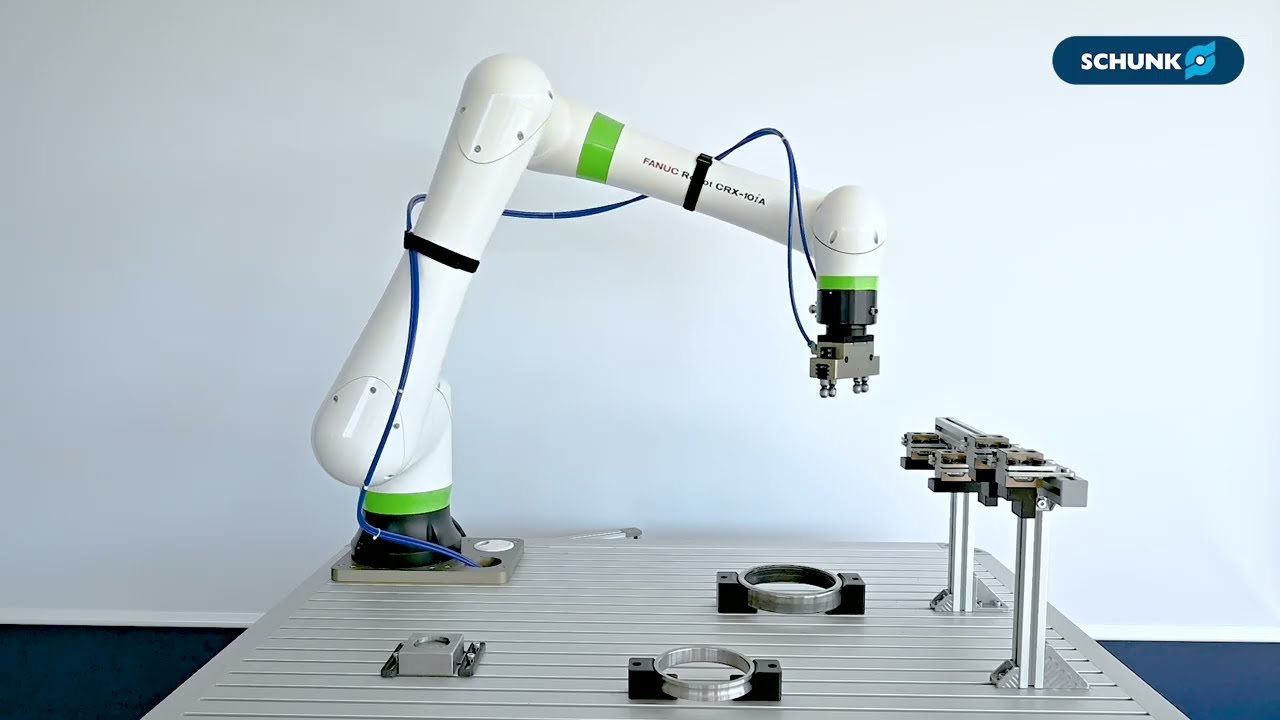

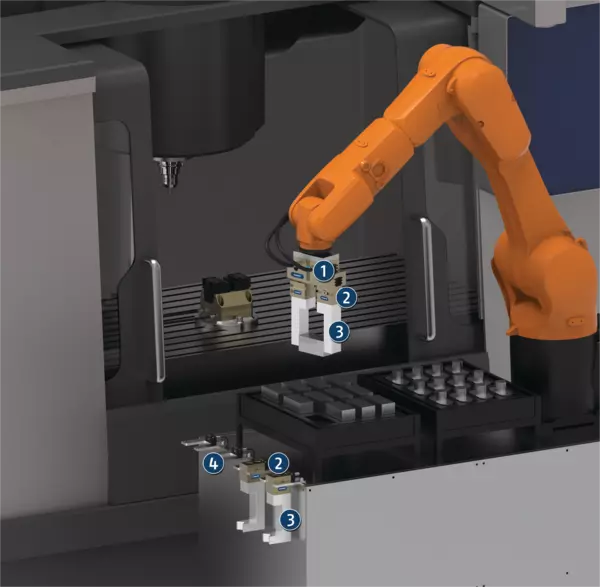

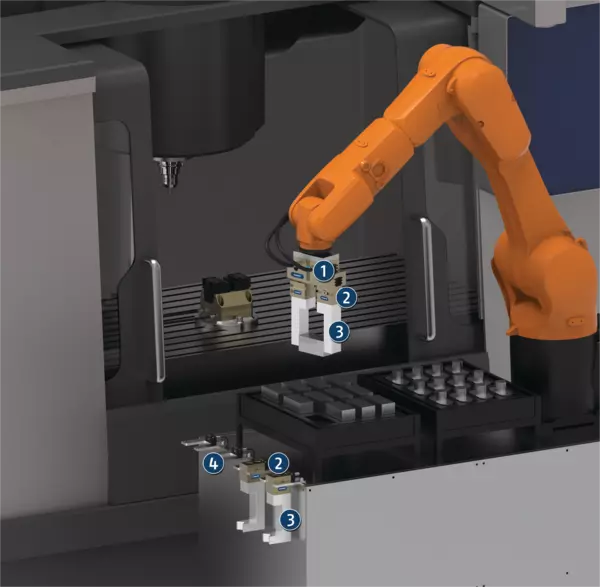

Anwendungsbeispiel

Anwendungsbeispiel

Greifeinheit mit Backenschnellwechselsystem zum automatischen Wechsel der werkstückspezifischen Greiferfinger

- 1

-

2-Finger-Parallelgreifer PGN-plus-P

- 2

-

Jaw quick-change system BSWS-R

- 3

-

Workpiece-specific gripper fingers

- 4

-

Deposit station