In many industrial manufacturing operations, randomly arranged and non-positioned parts are picked from a inlet belt conveyor, tray or preparation table.

They are then further processed, separated or fed to a machine.

Automated handling using robots, grippers and vision systems is demanding and requires experience in image processing, lighting and process technology. With its 2D Grasping Kit, SCHUNK is now offering a complete solution that makes it much easier to get started with automated object handling.

Our experts will be happy to advise you mechatronics@de.schunk.com

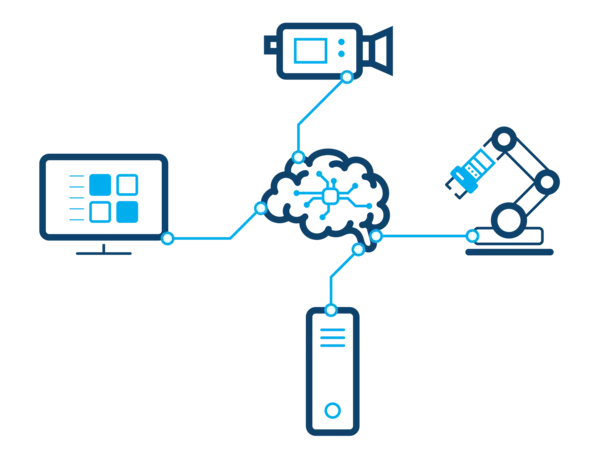

The perfectly matched application kit for gripping and placing non-position-oriented workpieces consists of a camera system and lens, an application-specific gripping system, SCHUNK's own industrial PC (SVC) as well as a plug-in for easy integration into the robot control system. The core of the system is the AI software developed by SCHUNK, which ensures reliably recognition, even under changing light conditions. All components in the kit are precisely matched to each other and are process reliable.

Without prior knowledge of image processing system programming possible

The software can determine gripping points independently

Easy commissioning without prior knowledge thanks to guided software

Automated calculation of interfering contours of fingers and workpiece

The software adapts itself to not optimal lighting conditions and changing backgrounds

Risk reduction and easier commissioning due to application validation in the CoLab

With the 2D Grasping Kit, users from many industries realize pick & place applications of randomly arranged parts on a single level - for example from a vibrating table, assembly line or load carrier. The metalworking industry, the automotive sector, companies in production engineering and logistics as well as from the life-science sector gain reliability, process precision and benefit from higher output using the kit.

If you have any questions about your specific application, we will be happy to help you mechatronics@de.schunk.com

In the CoLab, the SCHUNK Application Center, we can test your planned application for camera-based gripping.

We support you with feasibility studies with your workpiece, process analyses and demonstrations of your process. This way you can minimize your risk and save time during commissioning.

Get in touch now with your SCHUNK consultant on site so we can discuss and develop your application.