The recycling of materials – whether plastic, metal, wood, paper or biomass – has never been as important as it is today, and it continues to grow in importance. After all, transforming from a linear to a circular economy in all areas will form the basis for sustainable living and economic activity that focuses on saving resources. With shredding and briquetting machines as well as dewatering presses, WEIMA Maschinenbau makes a significant contribution to enabling companies of all sizes and from all industries to process and recycle material waste. "Shredding is the basis for making material recycling and the circular economy feasible in the first place," explains Marcus Weller, Team Leader and Production Manager Components at WEIMA Maschinenbau in Abstatt. "We build robust machines for all businesses, from small carpentry workshops to large industrial operations. These are, for example, briquetting machines that compact sawing or milling waste from parts processing and make it transportable. The portfolio also includes dewatering presses to recover coolants and lubricants from processing residues, as well as liquid residues from various types of packaging. WEIMA also supplies shredders for paper, documents, and used banknotes," says Weller. "Each machine is tailored to the customer's specific needs. That is why we produce with a very high level of vertical integration. The demanding machining of parts requires the use of the highest quality components."

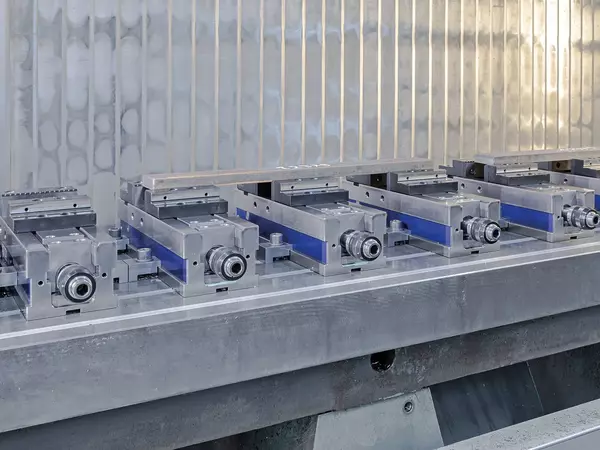

At its mechanical production facility in Abstatt, WEIMA mills, turns, and grinds parts for a wide variety of shredders, granulators, and presses. SCHUNK modules are used at various machining stations, including clamping systems and toolholders. "After all, SCHUNK comes from the region," says Marcus Weller, "and it is important for us to have regional partners. However, we not only appreciate the short distances, but above all the quality and reliability of the products and the service that SCHUNK offers us," explains the production manager. Thanks to the close cooperation, SCHUNK has provided the machine manufacturer with the new Adapt-R adapter jaws for the "Deckel Maho DMF 220 Linear" vertical milling center – and a whole series at that. Eight machine vises are installed in a row on the table for processing medium-sized and long workpieces. The SCHUNK adapter jaws now enable the use of application-specific top jaws on third-party vises. With 32 variants from SCHUNK, users can realize an optimal, application-specific clamping solution; until Adapt-R adapter jaws became available, it was not possible to use this broad portfolio with a competitor's vise.

The top jaws that now ensure production optimization and a productivity boost at WEIMA are the "Carbide-Grip" attachment jaws from SCHUNK, which securely clamp hardened workpieces up to 58 HRC (Rockwell hardness). The special feature of these Carbide-Grip jaws are the patented 92 HRC carbide pins, which grip the workpiece with their "claws" during clamping. The positive locking results in stable and reliable workpiece clamping. "This offers advantages if you need to clamp tightly," explains Marcus Weller. "The holding force is now greater and the clamping of the workpiece is much more secure. We can therefore increase the speed of machining and shorten throughput times." The top jaws with the tungsten carbide-coated carbide pins offer even more advantages: Lower clamping forces are required thanks to the form-fit connection with the clamped workpiece, preventing deformation in sensitive workpieces with small wall thickness values. "Without the pin top jaw, we used to have to clamp the blank more deeply and we needed more raw material," says Marcus Weller. "Overall, we can now machine faster and save time. This is reflected in reduced production and unit costs."

The concave shape of the carbide pins creates a large-area connection between the workpiece and the profile. This results in a vibration-resistant set-up, which is particularly relevant for long workpieces. "But even with small workpieces that are only fixed to the table with a vise, the advantages of the Carbide-Grip jaws are clearly noticeable, because we save time and material," confirms Weller. "The fact that we can use the adapter jaws to access SCHUNK's broad portfolio of top jaws without having to change our previous solution on the machine table gives us flexibility. We can use the adapter jaws universally and design the clamping solutions for different machining operations with a perfect fit," says Weller, drawing on knowledge from his everyday work.

The costs of the initial investment in Adapt-R adapter jaws are quickly amortized, since the top jaws from SCHUNK are cheaper than comparable competitors' products. Another advantage is the reduction in set-up time and process optimization – on the one hand thanks to the specific use of the precisely fitting attachment jaw, as WEIMA has done, and on the other hand thanks to the quick-change function on some variants. In any case, customers can continue to use their existing vises, resulting in sustainability and greater cost-effectiveness. Logistics and process planning also become easier – further advantages for users, because thanks to the adapter jaws, the same top jaws can be used on different vises. Replacement is quick thanks to simple handling, so that the new clamping solution is immediately ready for use.