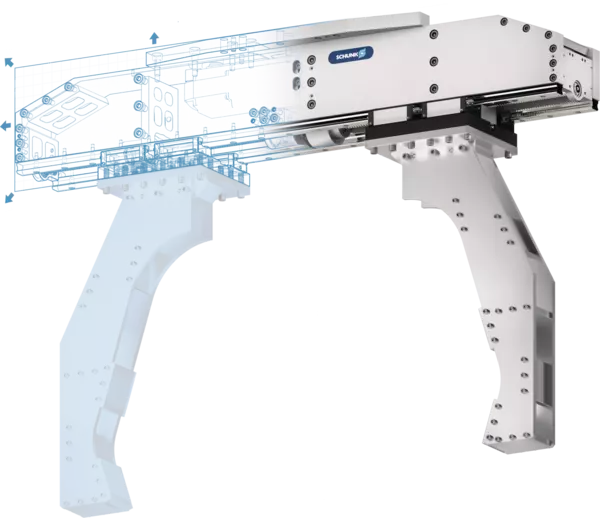

ELG

Customized and configurable long-stroke gripper

Electrical 2-finger parallel gripper with long jaw stroke, high gripping force and profiled rail guide for the use of long gripper fingers

With a gripping force of up to 12,000 N

The SCHUNK ELG is the latest highlight among the configurable grippers. It is used for handling large, heavy parts in the packaging, automotive, white goods and logistics industries, among others, and is actuated by an electric drive with a freely adaptable servomotor. The gripper can be finely adjusted and continuously positioned over the entire stroke from 100 to 400 mm. It has a unique force-stroke ratio and offers an instantly available and controllable gripping force of up to 3,000 N in size 30 to 12,000 N in size 120.

Advantages:

- High degree of flexibility due to the large jaw stroke and high gripping force

- Adaptable drive motor for flexible actuation and easy integration into existing control concepts

- Position- and torque-controlled movement of the gripper for the highly flexible gripping of a wide range of geometries and types of parts

- Food-grade lubrication

The product contains food-compliant lubricants as standard. The requirements of standard EN 1672-2:2020 are not fully met. The corresponding. NSF certificates can be accessed at https://info.nsf.org/USDA/Listings.asp can be called up with the help of the lubricant information in the operating manual. Components such as rolling bearings, linear guides, or shock absorbers are not provided with food-compliant lubricants.