The metal-cutting industry is currently facing difficult challenges. High productivity at low manufacturing costs and high factory quality are essential prerequisites for sustainability, profitability and competitiveness. Digitalization is considered to be the greatest challenge in the manufacturing industry. However, it also offers opportunities for companies in creating processes more precisely, reliably, and faster. With intelligent solutions and components from SCHUNK, we are contributing to maximum process stability and laying the foundation for a digital future in industry.

With the iTENDO², it has been possible to combine the excellent features of TENDO hydraulic expansion technology with the possibilities of digital process monitoring in one toolholder. If one looks into the process starting from the place of metal cutting, the iTENDO² intelligent toolholder is the first non-wear part, "closest-to-the-part," and therefore it is ideal for signal acquisition.

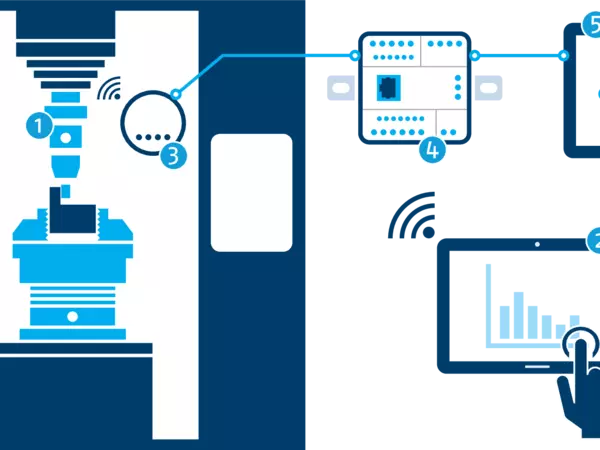

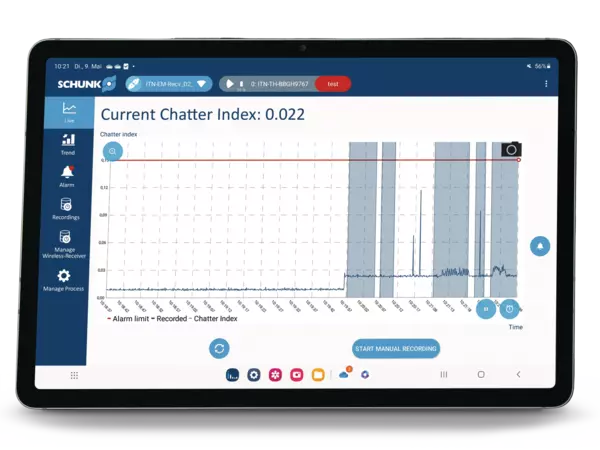

Getting started with transparent data acquisition with the iTENDO² is really easy. Connect the toolholder to the pad with a simple click and the iTENDO² can immediately detect irregularities, and help you to work even more efficiently in various machining processes. On the tablet PC, the process can be followed in real time, recorded and started by setting the exact limits in the parameters for automatic recording.

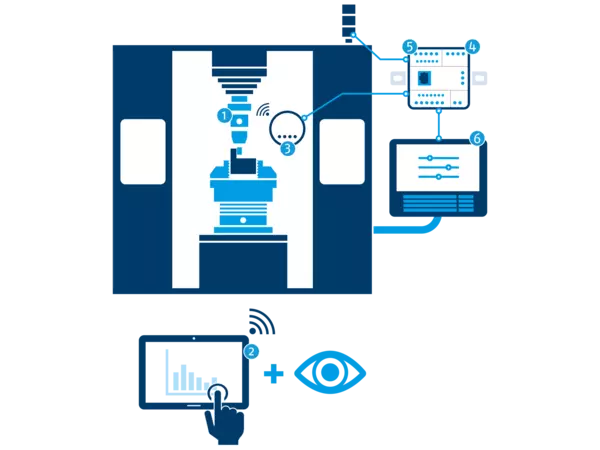

By recording the vibration data on the last non-wearable part, the iTENDO² enables high data quality. This data helps to quickly identify problems in processes and improve processes. The enhancement package iTENDO² easy connect now offers the possibility of an easy connection of the toolholder technology to the machine and the existing process monitoring system.

With the easy connect expansion package, the data of the iTENDO² are received wireless from a receiver in the machine room, transferred to a control cabinet module, and provided to the process monitoring system via an analog output (0 – 10 volts).

The function expansion iTENDO² easy monitor enables machine operators to get easily startet into process monitoring. As with the easy connect package, the data of the iTENDO² is received by a wireless receiver and passed on to a control cabinet module. The package also has software extensions that can be accessed using the supplied iTENDO² pad.

By means of the software upgrade, processes and limits can be defined on up to 64 memory locations. Moreover, easy monitor offers the possibility to configure life and trend alarms, which can be used for reactions such as fault lamps or machine stops. The easy monitor package offers an easy process monitoring with an intuitive and user-friendly interface.

Getting started with transparent data acquisition with the iTENDO² is easier than ever. Connect the toolholder to the tablet PC with a simple click and the iTENDO² can immediately detect irregularities, and help you to work even more efficiently in various machining processes. On the tablet PC, the process can be followed in real time, recorded and started by setting the exact limits in the parameters for automatic recording. In our video, we show how user-friendly and uncomplicated the handling is.