The aerospace industry is one of the most complex sectors, as it integrates aspects of information technology, robotics, measurement and control technology, and other areas. Materials, components, and systems must be able to withstand extreme stresses. A quality assurance system ensures that all measures are taken to prevent errors. Despite the above-average level of innovation, the time factor also plays a decisive role. SCHUNK is your reliable partner in aerospace. We support both aircraft construction projects and research and development activities for space travel.

With SCHUNK Engineering as your partner, specific aerospace requirements are jointly translated into solutions: customized gripping, clamping, and handling technology as well as simulation that ensure reproducible quality, component protection, and high process reliability across all processing stages.

In the extreme conditions of the aerospace industry, structural components must meet the highest standards. These components form the backbone of aircraft and spacecraft and not only contribute to stability, but must also combine low weight and high strength. Continuous innovation in materials science enables the development of lightweight yet extremely durable structural components. These evolutionary advances are crucial for the efficiency, performance and safety of aircraft and spacecraft.

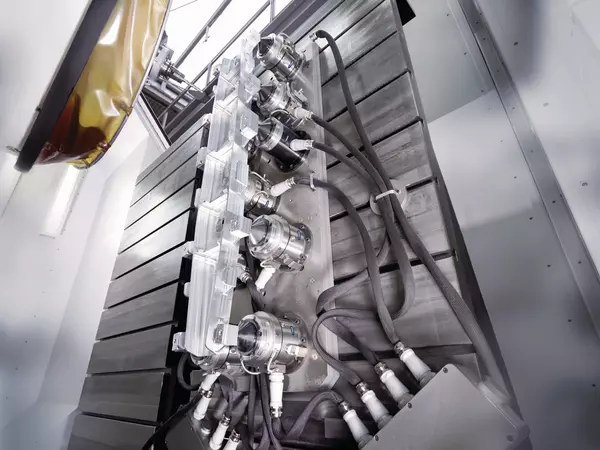

Structural components make high demands on set-up, which requires costly and time-consuming adjustments. With controlled flexibility, the VERO-S Aviation drastically reduces the need of set-ups by enabling effective unclamping of the components.

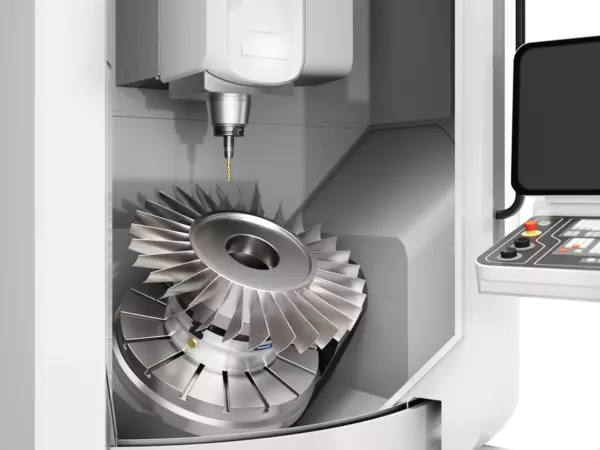

Driving mechanism parts play a key role in the aerospace industry by influencing the performance and efficiency of aircraft. From turbine blades to high-temperature alloys, these components have to withstand the highest of loads. Advances in materials technology and precision manufacturing enable the development of engine parts that are not only lighter, but can also withstand extreme temperatures and pressures. Continuous innovation in this area is crucial to improving fuel efficiency, reducing emissions and increasing the overall performance of aerospace engines.

For clamping sensitive components such as housing and turbine parts, we rely on deformation-low set-up. This is how we ensure integrity during the machining process and meet the highest precision requirements, even for rotationally symmetrical components.

Landing gear components are of central importance in the aerospace industry, as they are essential for the safe landing and take-off of airplanes. These highly specialized components have to withstand extreme loads, from landing shock absorbers to brake systems. Thanks to continuous innovation in materials science and engineering, chassis parts are becoming lighter, more durable and more efficient. Precision in design and production is crucial in order to meet the requirements for safety, weight reduction and performance and thus make a significant contribution to the development of modern aerospace technologies.

When clamping the aircraft rims, we attach great importance to minimizing the risk of deformation. Here we are using the 6-jaw chuck that enables deformation-free clamping. This is how we ensure precise machining and compliance with quality standards.

In CoLab, the SCHUNK Application Center, we work with you to test your planned application. We support you with feasibility studies, process analyses and demonstrations of your process. This way you can minimize your risk and save time during commissioning. Get in touch now with your SCHUNK consultant on site so we can discuss and develop your application.