SRM 25-H-180-3-SI

ID 1347273

- Ángulo de giro: 180 °

- Posibilidad de ajuste de la posición final: 3 °

- Amortiguación de fin de carrera: amortiguador hidráulico

- Torque: 5.95 Nm

Technical details

| Amortiguación de fin de carrera | amortiguador hidráulico |

|---|---|

| Ángulo de giro [°] | 180 |

| Torque [Nm] | 5.95 |

| Número de posiciones intermedias | Ninguna |

| Clase de protección IP | 65 |

| Peso [kg] | 1.93 |

| Consumo de fluido (2 x ángulo nominal) [cm³] | 84.0 |

| Presión nominal de servicio [bar] | 6.0 |

| Presión de trabajo mín. [bar] | 4.0 |

| Presión de trabajo máx. [bar] | 6.5 |

| Diámetro del tubo de conexión | 6 x 3.9 x 1.05 |

| Temperatura ambiente mín. [°C] | 5.0 |

| Temperatura ambiente máx. [°C] | 60.0 |

| Sala blanca ISO 14644-1:2015 | 5 |

| Precisión de repetición [°] | 0.07 |

| Diámetro del taladro central [mm] | 17.1 |

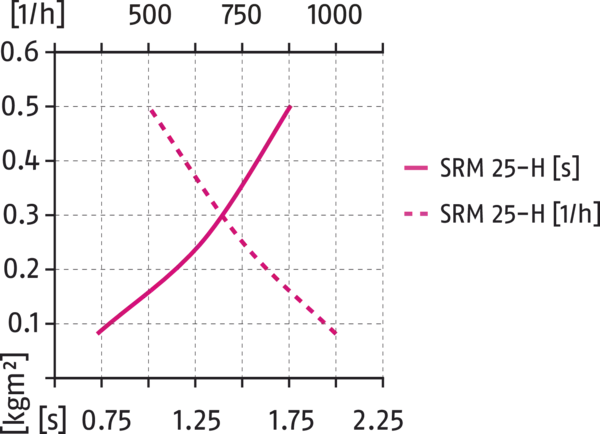

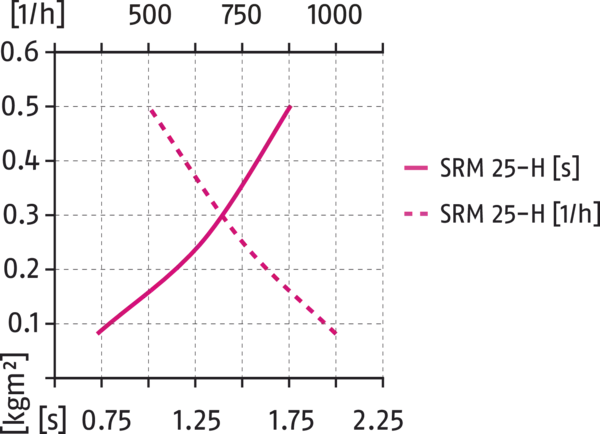

| Momento de inercia máx. admisible de la masa [kgm²] | 0.5 |

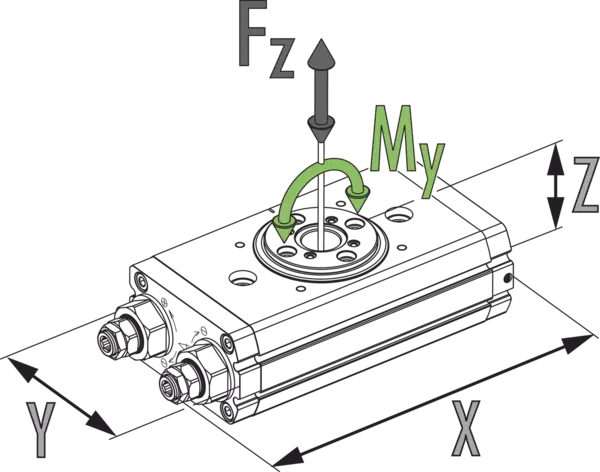

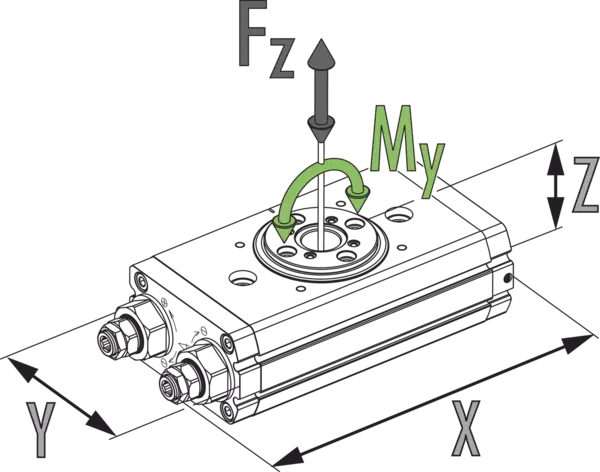

| Momento My máx. [Nm] | 64.0 |

| Máx. fuerza axial Fz máx. [N] | 2250.0 |

| Opción para los sensores de proximidad inductivos | sí |

| La detección de posición se puede ajustar | sí |

| Versión para sensores inductivos, ajustable | sí |

Dimensiones y cargas máximas

Inercia J* máxima admisible

Dimensiones y cargas máximas

Las fuerzas y pares indicados son valores estáticos, válidos para la unidad básica y deben darse simultáneamente. Se debe regular el movimiento de giro para garantizar que no se produzcan impactos ni rebotes. De lo contrario, la vida útil del equipo puede disminuir.

Inercia J* máxima admisible

- X-axis:

- Tiempo de giro

- Y-axis:

- Momento de inercia de la masa

- X-axis top:

- Ciclos por hora

General notes about the series

Repeat accuracy

is defined as a distribution of the end position for 100 consecutive cycles.

Pinion position

is always shown in the left end position. The pinion rotates from here to the right in clockwise direction. The arrow makes the direction of rotation clear.

Pinion screw connection diagram

When setting a swivel angle smaller than 90°, the left end stop must be completely turned in. This means that the left end position has a screw connection diagram on the pinion which is clockwise turned by 90° compared to the main view, which shows a swivel angle of 180°.

Customized angle of rotation

More swivel angles are available on request.

Torque in the end positions

Please note that the final angular degrees (approx. 2°) before the end position can only be approached using the force of a single drive piston. For this reason, double actuated modules only have about half the rated torque available in this area.

Travel to the pneumatic middle position

is carried out using only half of the nominal torque.

Swiveling time

is the rotation time of pinion/flange around the nominal rotation angle. Valve switching times, hose filling times, or PLC reaction times are not included and are to be considered when cycle times are calculated.

Standard conditions

The technical data shown refers to an environment of 20 °C and atmospheric pressure.

Housing material

Aluminum (extruded profile)

Actuation

pneumatic, with filtered compressed air as per ISO 8573-1:2010 [7:4:4].

Operating principle

Double piston rack and pinion principle

Scope of delivery

Swivel unit in the ordered variant, accessory kit (centering sleeves, O-rings for direction connection/detailed contents see operating manual) and safety information. Product-specific instructions can be downloaded at schunk.com/downloads-manuals.

Warranty

24 months

Service life characteristics

on request