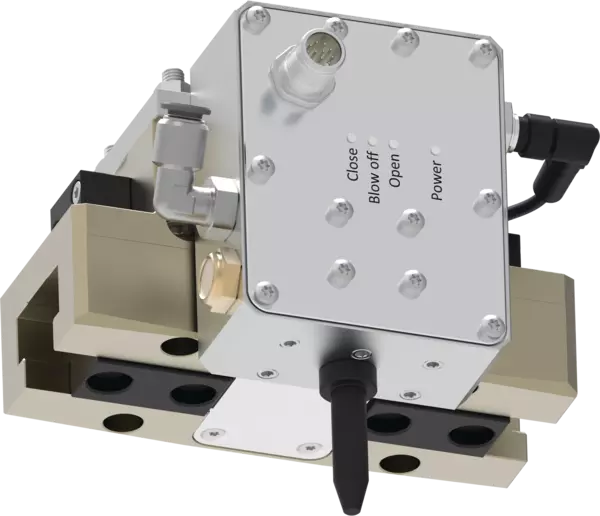

MTB SG-JGP-P 80-1

ID 1490825

- Stroke per jaw: 8 mm

- Closing force: 550 N

- Opening force: 610 N

- Power supply: 24 V DC

- Magnetic circuit: 170 mA

- Max. ambient temperature: 50 °C

Technical details

| Sensor system | pre-assembled, 2-way magnetically adjustable |

|---|---|

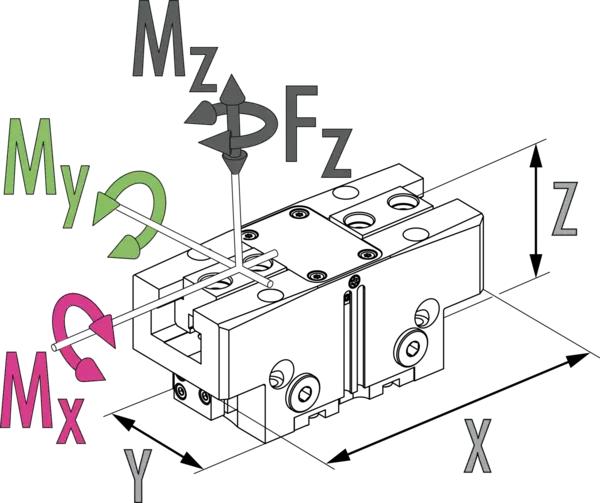

| Length X [mm] | 96.0 |

| Width Y [mm] | 100.0 |

| Height Z [mm] | 116.0 |

| Weight [kg] | 0.99 |

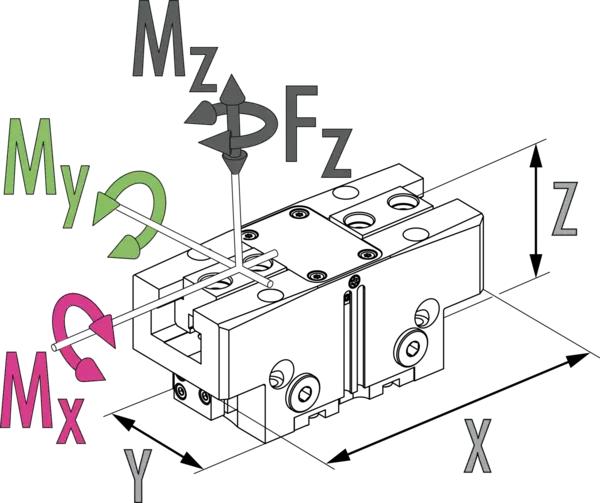

| Moment Mx max. [Nm] | 61.0 |

| Moment My max. [Nm] | 86.0 |

| Moment Mz max. [Nm] | 50.0 |

| Stroke per jaw [mm] | 8.0 |

| Closing force [N] | 550.0 |

| Opening force [N] | 610.0 |

| Recommended workpiece weight [kg] | 2.75 |

| Max. permissible finger length [mm] | 110.0 |

| Max. permissible weight per finger [kg] | 0.6 |

| IP protection class of gripper | 40 |

| IP protection class of valve box | 67 |

| Min. ambient temperature [°C] | 5.0 |

| Max. ambient temperature [°C] | 50.0 |

| Min. operating pressure [bar] | 2.5 |

| Max. operating pressure [bar] | 7.0 |

| Nominal operating pressure [bar] | 6.0 |

| Min. air purge pressure [bar] | 0.5 |

| Max. air purge pressure [bar] | 1.0 |

| Closing time [s] | 0.07 |

| Opening time [s] | 0.07 |

| Cylinder volume per double stroke [cm³] | 29.0 |

| Fluid consumption blow-off nozzle [cm³/s] | 3000.0 |

| Repeat accuracy [mm] | 0.01 |

| Cable connector | M12, A-coded |

| Nominal voltage [V DC] | 24.0 |

| Nominal current [mA] | 170.0 |

| Max. current [mA] | 500.0 |

| Communication interface | digital I/O |

| Number of digital inputs | 4.0 |

| Number of digital outputs | 2.0 |

Dimensions and maximum loads

Maximum permitted finger projection

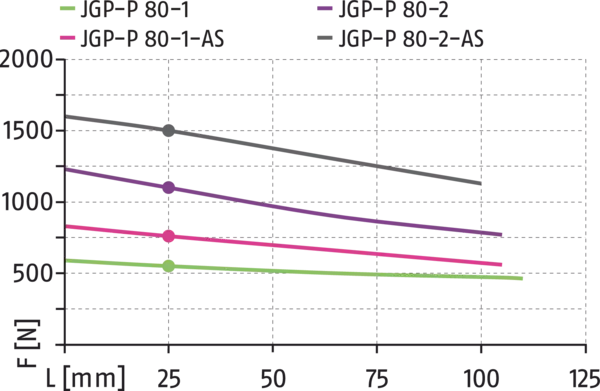

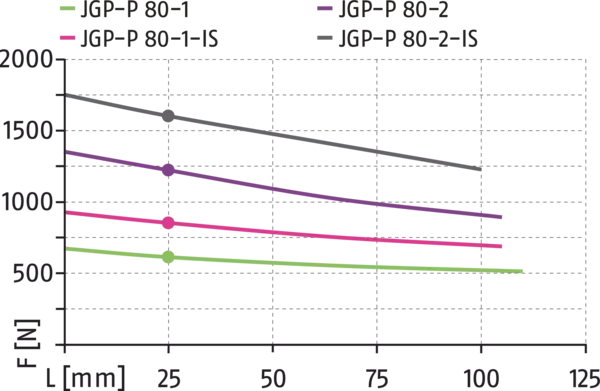

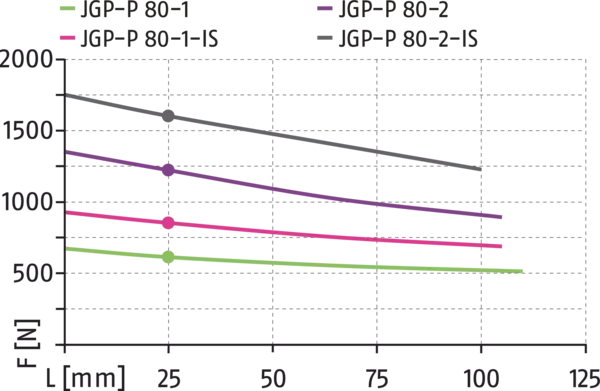

Gripping force O.D. gripping

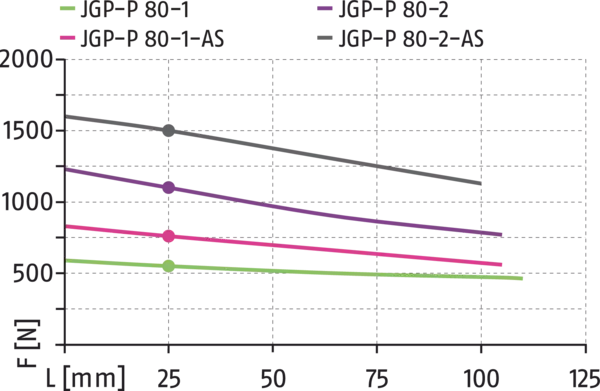

Gripping force I.D. gripping

Maximum permitted finger projection

Dimensions and maximum loads

The indicated moments and forces are statical values, apply for each base jaw and may appear simultaneously. Loads may additionally occur to the moment produced by the gripping force itself.

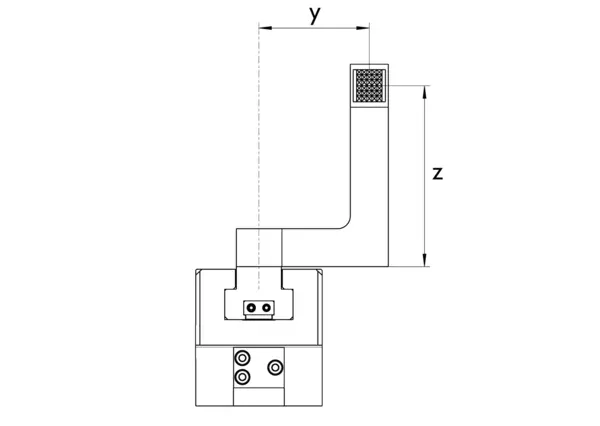

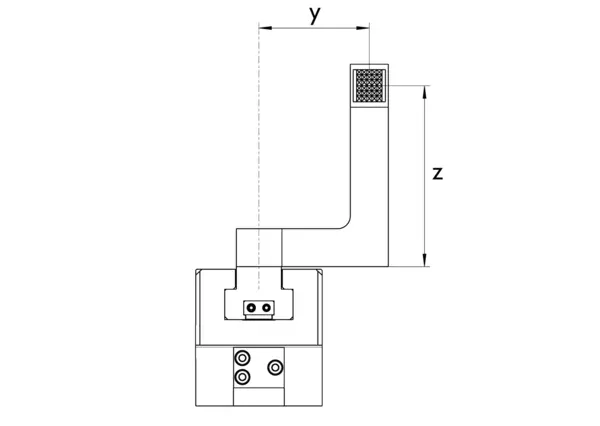

Maximum permitted finger projection

Gripping force O.D. gripping

- X-axis:

- Finger length

- Y-axis:

- Gripping force

Gripping force I.D. gripping

- X-axis:

- Finger length

- Y-axis:

- Gripping force

Maximum permitted finger projection

Lmax is equivalent to the maximum permitted finger length, see the technical data table.

- green

- Permitted range

- grey

- Inadmissible range

General notes about the series

Gripping force

is the arithmetic sum of the individual force applied to each jaw at distance P (see illustration).

Finger length

is measured from the reference surface as the distance P in direction to the main axis. The maximum permissible finger length applies until the nominal operating pressure is achieved. With higher pressures, the finger length must be reduced proportionally to the nominal operating pressure.

Repeat accuracy

is defined as a distribution of the end Position for 100 consecutive strokes.

Workpiece weight

is calculated for force-fit gripping with a coefficient of static friction of 0.1 and a safety factor of 2 against workpiece slippage at acceleration due to gravity g. For form-fit or capture gripping, there are significantly higher permissible workpiece weights.

Closing and opening times

are movement times of the base jaws only, without application-specific gripper fingers, incl. valve switching times. PLC reaction times are not included in the above-mentioned times and must be taken into consideration when determining cycle times.

Housing material

Aluminum

Base jaw material

Steel

Actuation

pneumatic, with filtered compressed air as per ISO 8573-1:2010 [3:4:3]

Warranty

24 months