ERD 04-40-D-D-2-H1G

ID 1488528

- Krouticí moment: 0.4 Nm

- Jmenovitý proud: 0.43 A

- Napájení: 530 V

- Třída ochrany IP: 40

Technical details

| Max. operating pressure [bar] | 6.0 |

|---|---|

| Nominal current [A] | 0.43 |

| SIL certification | 2 |

| Peak torque [Nm] | 1.2 |

| Max. permissible mass moment of inertia [kgm²] | 0.008 |

| Intermediate circuit voltage [V] | 530.0 |

| Output signal | DRIVE-CLiQ |

| Number of pneumatic feed-throughs | 2.0 |

| Weight [kg] | 1.2 |

| Max. voltage (DC) [V] | 60.0 |

| IP protection class | 40 |

| Min. ambient temperature [°C] | 10.0 |

| Max. ambient temperature [°C] | 40.0 |

| Repeat accuracy [°] | 0.01 |

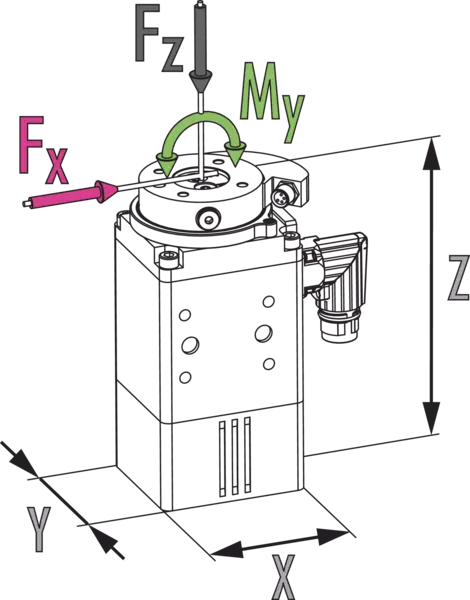

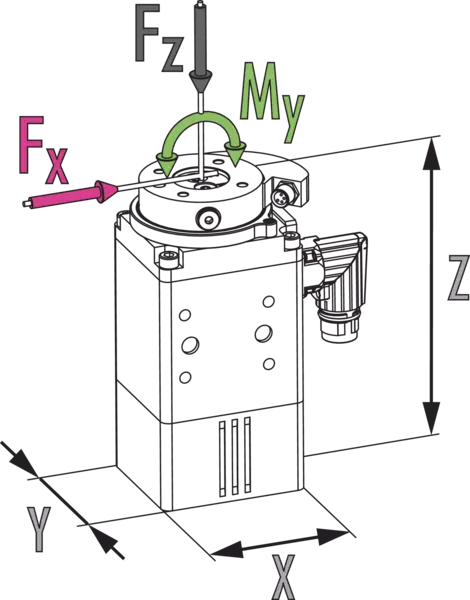

| Moment My max. [Nm] | 2.5 |

| Force Fx max. [N] | 150.0 |

| Force Fz max. [N] | 150.0 |

| Max. current [A] | 1.29 |

| Max. current [A] | 1.0 |

| Max. rotational speed [1/min] | 600.0 |

| Height Z [mm] | 139.0 |

| Width Y [mm] | 60.0 |

| Length X [mm] | 68.0 |

| Number of electrical feed-throughs | 4.0 |

| Nominal torque [Nm] | 0.4 |

| Encoder system | Encoder (absolute) |

| Angle of rotation [°] | > 360 |

| Cleanroom class ISO 14644-1:2015 | 2 |

| H1 grease version | yes |

Dimensions and maximum loads

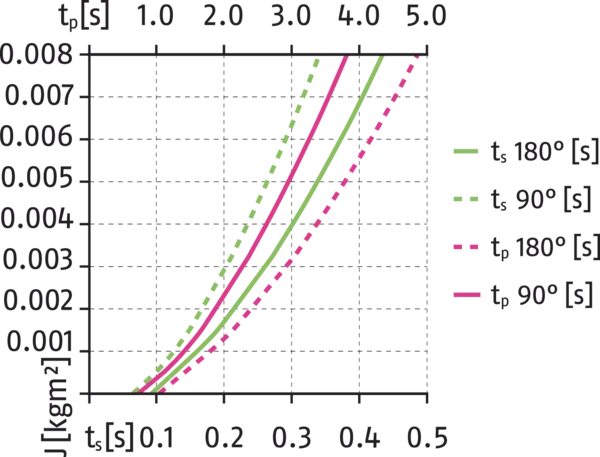

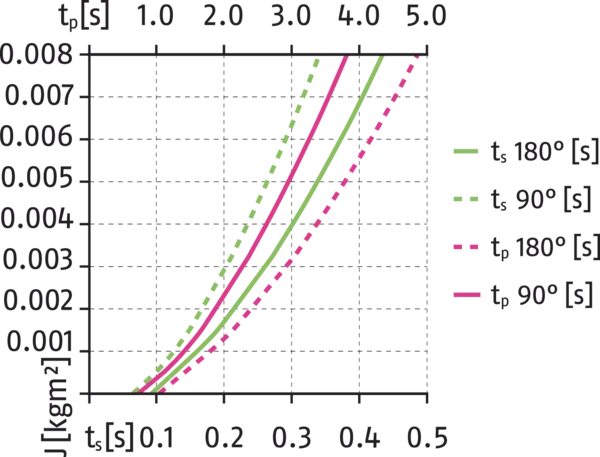

Swivel time diagram

Dimensions and maximum loads

Moments and forces may occur simultaneously.

Swivel time diagram

- X-axis:

- Swiveling time

- Y-axis:

- Mass moment of inertia

- X-axis top:

- Cycles per hour

General notes about the series

Swiveling times

The swiveling times are purely the times when the module moves from rest position to rest position. Delays caused by the PLC or the drive controller are not included and to be taken into consideration when determining cycle times. Load-dependent rest periods may have to be included in the cycle time.

Layout or control calculation

Verifying the sizing of the selected unit is necessary, since otherwise overloading can result. Please contact us for assistance.

Repeat accuracy

The repeat accuracy is defined as the spread of the target position after 100 consecutive positioning cycles.

Ambient conditions

The modules are primarily designed for the use in clean to slightly contaminated environments. Please note that the life time of the modules can shorten if they are used in harsh ambient conditions, and that SCHUNK cannot assume liability in such cases.

Safety notes

Caution: Magnetic field! This particularly applies for persons with implanted medical devices, such as pacemakers, hearing aids, etc.

Nominal currents

The rated currents can be permanently actuated. With regard to all the currents which are ranging above the nominal current up to the maximum current, the notes of the individual product documentation has to be respected.

Cleanroom class ISO 14644-1:2015

Housing material

Aluminum alloy, coated

Drive

Torque motor, 3-phase

Stroke measuring system

Motor feedback system for absolute measurement, multiturn version (up to 4,096 RPM), with HIPERFACE and DRIVE-CLiQ interfaces

Drive controller

Bosch Rexroth IndraDrive Cs control unit is supported as standard; matching parameters supplied on DVD, other manufacturers available on request.

Scope of delivery

Enclosed accessory pack containing centering sleeve, assembly and operating manual, commissioning DVD for SCHUNK motors

Warranty

24 months

Service life characteristics

on request