RST-D 87-4

ID 315510

- Torque: 7.9 Nm

Technical details

| Angle of rotation [°] | 90.0 |

|---|---|

| Pitch | 4.0 |

| Direction of rotation | on both sides |

| Torque [Nm] | 7.9 |

| Weight [kg] | 2.9 |

| IP protection class | 50 |

| Locking time [s] | 0.1 |

| Unlocking time [s] | 0.1 |

| Min. ambient temperature [°C] | 5.0 |

| Max. ambient temperature [°C] | 60.0 |

| Min. operating pressure [bar] | 4.0 |

| Max. operating pressure [bar] | 8.0 |

| Nominal operating pressure [bar] | 6.0 |

| Cylinder volume per double stroke [cm³] | 53.0 |

| Repeat accuracy [°] | 0.06 |

| Run-out cycle ring [mm] | 0.02 |

| Axial run-out cycle ring [mm] | 0.02 |

| Parallelism cycle ring [mm] | 0.04 |

| Number of hydraulic shock absorber | 2.0 |

| Length X [mm] | 136.0 |

| Width Y [mm] | 100.0 |

| Height Z [mm] | 74.0 |

| Moment My max. [Nm] | 40.0 |

| Moment Mz max. [Nm] | 40.0 |

| Max. axial force Fz max. [N] | 3400.0 |

| Max. radial force Fr max. [N] | 1700.0 |

Dimensions and maximum loads

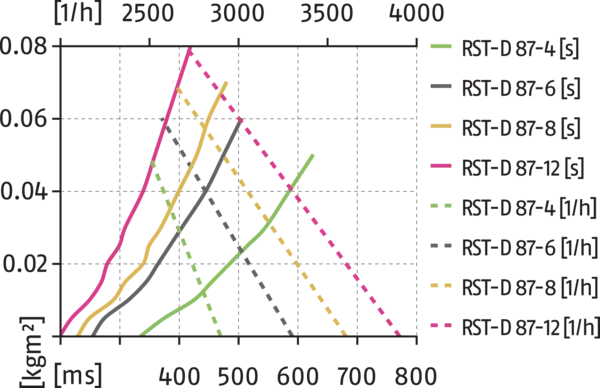

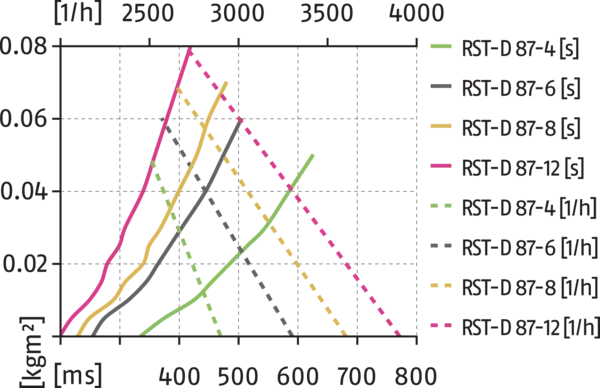

Swiveling time

Dimensions and maximum loads

The indicated moments and forces are statical values and may appear simultaneously. Throttling has to be done for ensuring that the rotary movement takes place without impact or bouncing. Otherwise the service life reduces.

Swiveling time

- X-axis:

- Swiveling time

- Y-axis:

- Mass moment of inertia

- X-axis top:

- Cycles per hour

General notes about the series

Repeat accuracy

is defined as a distribution of the end Position for 100 consecutive strokes.

Drive ring

The position of the drive ring is always drawn in basic position. From here, the ring turns clockwise or anti-clockwise.

Swiveling time

is the rotation time of pinion/flange around the nominal rotation angle. Valve switching times, hose filling times, or PLC reaction times are not included and are to be considered when cycle times are calculated.

Reference sensor

For monitoring the basic position, an inductive sensor can be attached, which will be actuated every 360°. It can be used for reference run or for checking if the control unit has counted correctly.

Swivel time depends on the payload

The shown diagrams are valid for nominal rotation angles, for the use with vertical swivel axis, or for centrical payloads with horizontal swivel axes, and at an operating pressure of 6 bar. The diagrams show the expected swivel time, and allows cycle per hour depending on the mass moments of inertia. The swiveling times need to be adjusted by using throttle valves, otherwise the life time could be reduced. We will be happy to help you designing other applications.

Total cycle time

The total cycle time consists of the swiveling time per cycle together with other required time intervals. See the operating manual for the exact calculation of the total cycle time.

Housing material

Aluminum alloy, anodized

Actuation

pneumatic, with filtered compressed air as per ISO 8573-1:2010 [7:4:4].

Operating principle

Rack and pinion principle with back stroke freewheel

Scope of delivery

Centering elements, safety information (product-specific instructions available online)

Warranty

24 months

Service life characteristics

on request