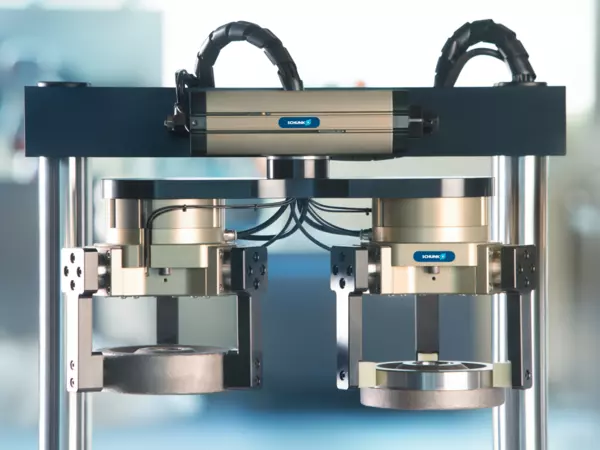

The SRM can be equipped with media feedthroughs and electrical feedthroughs to directly supply both pneumatic and electrical grippers.

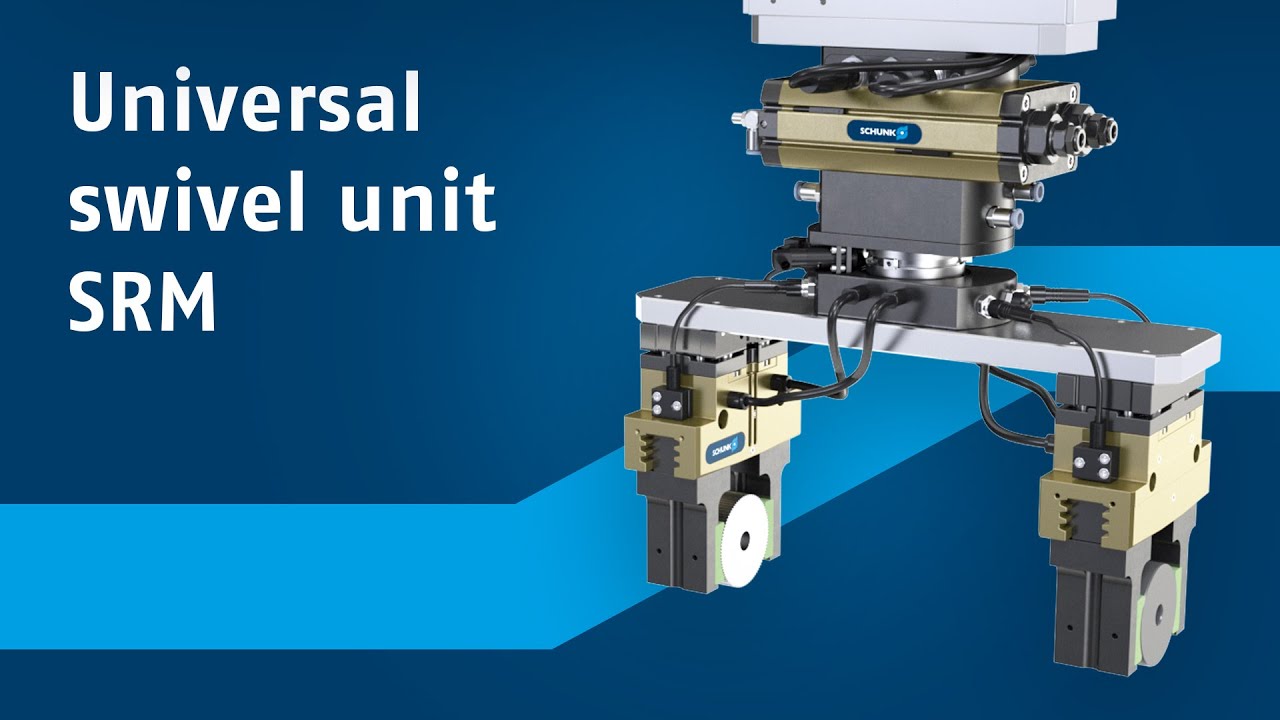

SRM

Universal swivel unit

Universally usable unit for pneumatic swivel and turning movements

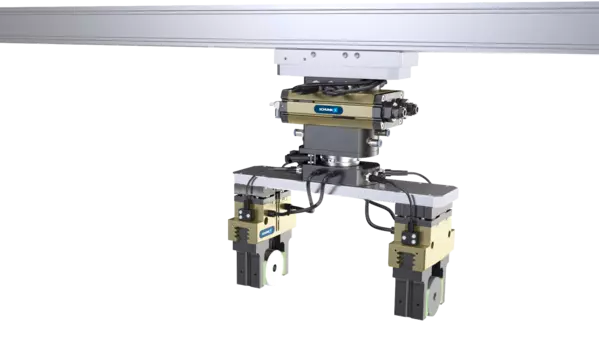

The pneumatic universal swivel unit means more performance and economy in production automation. Specially developed shock absorbers ensure maximum performance in the smallest possible space. The especially large center bore for feed-through of various media and a unique setup enable tailored, highly efficient solutions.

Take advantage of the benefits

- Robust and durable

• Robust and large flange connection diagram

• High load and torque absorption due to the lack of play in the pre-loaded bearing of the pinion

• High-quality FwieKM seals with high resilience and long service life - Maximum performance

• Unique combination of high torque and increased mass moment of inertia for short swivel times

• High power density with compact design - Easy commissioning

• Preset damper stroke, therefore the customer must only adjust the air throttles

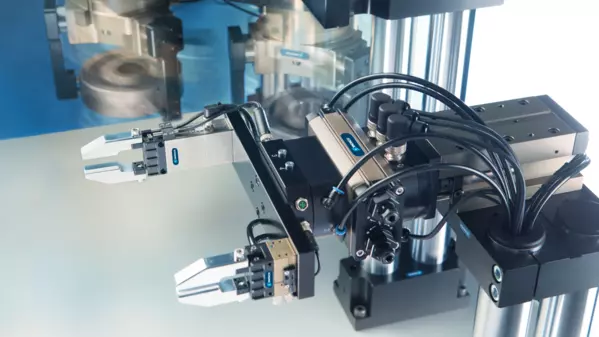

• Large center bore for simple feed-through of pneumatic supply lines and electric standard cables

• For the electrical media feed-through, the sensor cables can be inserted directly. The color-coding of the plug connectors simplifies the signal allocation

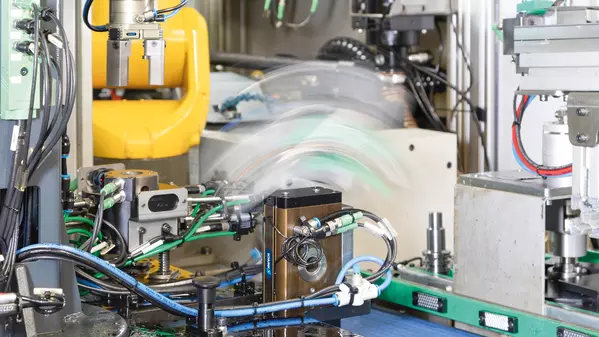

Applications

Product animation

The product animation shows the universal swivel unit SRM. In addition to the product description, it contains sections on commissioning and provides an overview of the available sizes and variants.