ORG 85

ID 304120

- Max. ambient temperature: 90 °C

Technical details

| Number of fingers | 6.0 |

|---|---|

| Triple jaws A: working principle | double-acting |

| Triple jaws A: stroke per finger [mm] | 21.0 |

| Triple jaws A: closing force [N] | 45.0 |

| Triple jaws A: opening force [N] | 55.0 |

| Triple jaws A: retraction stroke [mm] | 5.0 |

| Triple jaws A: retraction force [N] | 20.0 |

| Triple jaws A: cylinder volume per double stroke [cm³] | 11.0 |

| Triple jaws A: cylinder volume per double stroke [cm³] | 6.0 |

| Triple jaws B: working principle | one-way acting |

| Triple jaws B: stroke per finger [mm] | 15.0 |

| Triple jaws B: opening force [N] | 125.0 |

| Triple jaws B: fluid consumption per opening stroke [cm³] | 9.0 |

| Closing time [s] | 0.1 |

| Opening time [s] | 0.12 |

| Weight [kg] | 1.35 |

| Nominal operating pressure [bar] | 6.0 |

| Min. operating pressure [bar] | 4.0 |

| Max. operating pressure [bar] | 8.0 |

| Max. permissible finger length [mm] | 80.0 |

| IP protection class | 40 |

| Min. ambient temperature [°C] | 5.0 |

| Max. ambient temperature [°C] | 90.0 |

| Repeat accuracy [mm] | 0.02 |

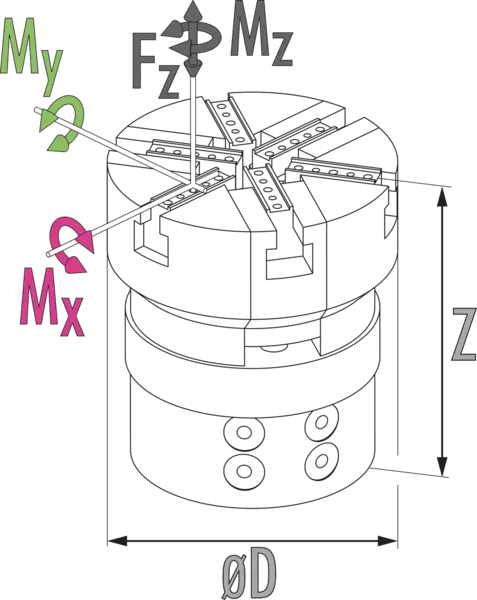

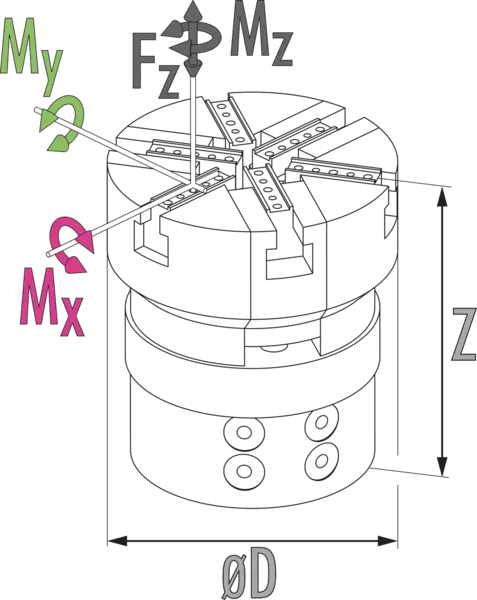

| Diameter D [mm] | 85.0 |

| Height Z [mm] | 98.0 |

| Moment Mx max. [Nm] | 10.0 |

| Moment My max. [Nm] | 8.0 |

| Moment Mz max. [Nm] | 6.0 |

| Max. axial force Fz max. [N] | 40.0 |

Triple jaws A and B can both be adjusted with regard to their opening stroke – the closed position remains unaffected.

Please contact SCHUNK to ensure ultimate installation compatibility.

Dimensions and maximum loads

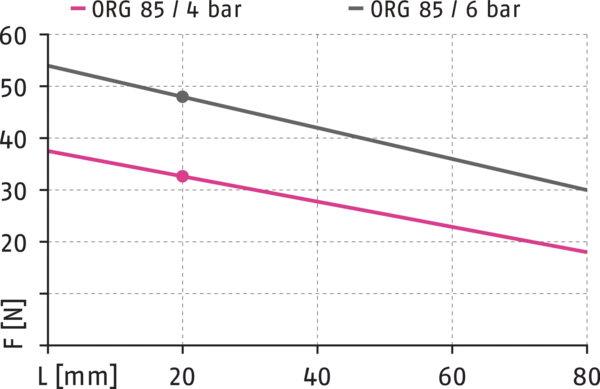

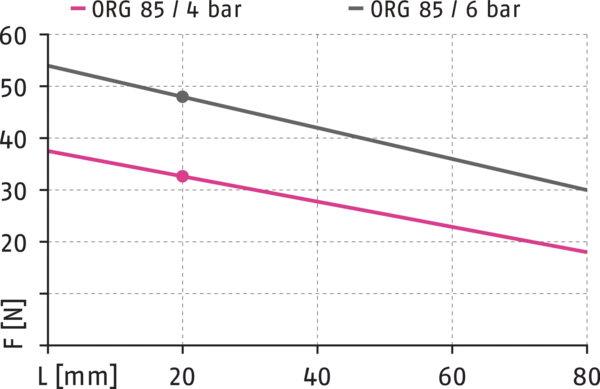

Triple jaws A outside gripping force

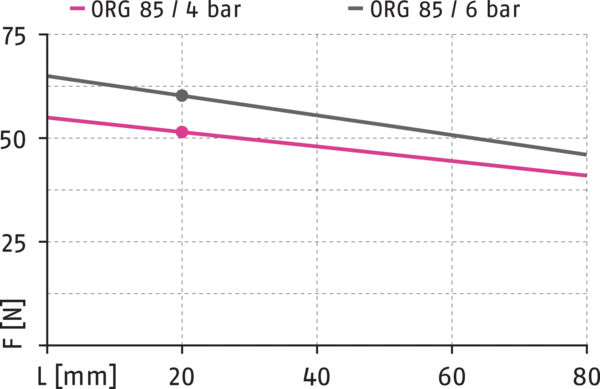

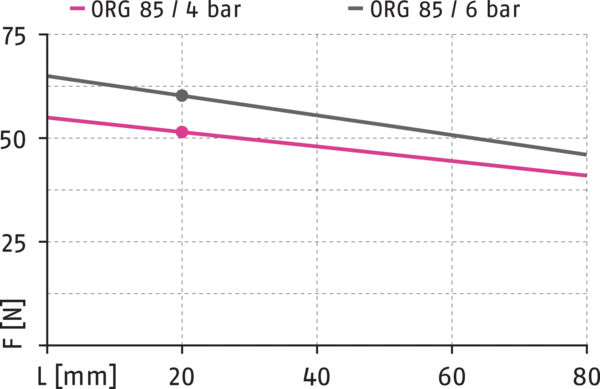

Triple jaws A inside gripping force

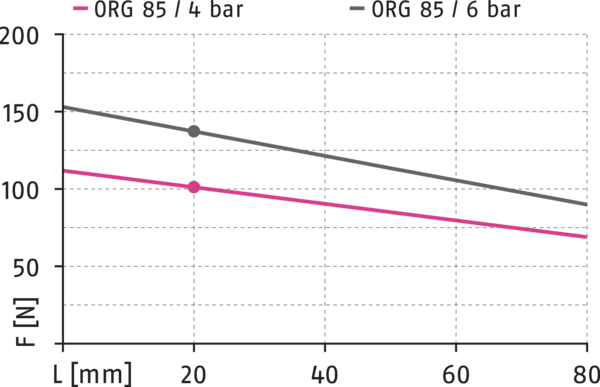

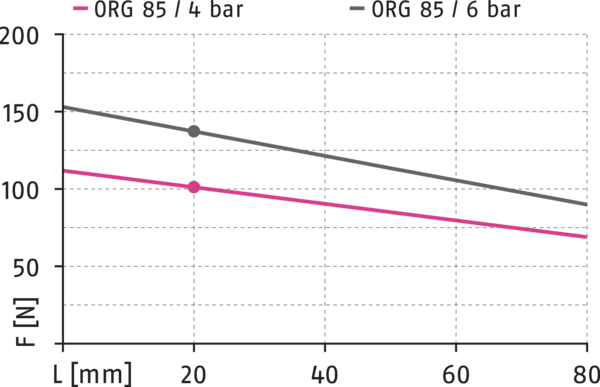

Triple jaws B inside gripping force

Dimensions and maximum loads

The indicated moments and forces are statical values, apply for each base jaw and may appear simultaneously. Loads may additionally occur to the moment produced by the gripping force itself.

Triple jaws A outside gripping force

- X-axis:

- Finger length

- Y-axis:

- Gripping force

Triple jaws A inside gripping force

- X-axis:

- Finger length

- Y-axis:

- Gripping force

Triple jaws B inside gripping force

- X-axis:

- Finger length

- Y-axis:

- Gripping force

General notes about the series

Gripping force

is the arithmetic sum of the individual force applied to each jaw at distance P (see illustration).

Finger length

is measured from the reference surface as the distance P in direction to the main axis. The maximum permissible finger length applies until the nominal operating pressure is achieved. With higher pressures, the finger length must be reduced proportionally to the nominal operating pressure.

Repeat accuracy

is defined as a distribution of the end Position for 100 consecutive strokes.

Workpiece weight

is calculated for force-fit gripping with a coefficient of static friction of 0.1 and a safety factor of 2 against workpiece slippage at acceleration due to gravity g. For form-fit or capture gripping, there are significantly higher permissible workpiece weights.

Closing and opening times

are movement times of the base jaws only, without application-specific gripper fingers. Valve switching times, hose fill times, or PLC reaction times are not included, and are to be considered when cycle times are calculated.

Operating principle

Two independent triple-finger combinations deform the O-ring in order to then install it.

Housing material

Aluminum

Base jaw material

Steel

Actuation

pneumatic, with filtered compressed air as per ISO 8573-1:2010 [7:4:4].

Warranty

24 months

Service life characteristics

on request

Scope of delivery

Centering sleeves, safety information (product-specific instructions available online)