When buying a car or designing a room, smart 3D configurators have established themselves as a matter of course. Industrial production often still relies on cost-intensive special solutions for production automation, which are associated with a complex process chain and long delivery times. However, ever smaller quantities and a simultaneous increase in customer expectations require short response times as well as affordable and networked solutions that require less intensive planning. The application expert SCHUNK shows a way to implement quickly available application-specific solutions with new configurable product series. The pneumatic and electric grippers, gripper fingers as well as chuck jaws for clamping devices can be individually adapted to the customer's requirements in a maximum of 4 steps. Even without any design knowledge. The license-free, browser-based web tools are freely available on the SCHUNK website.

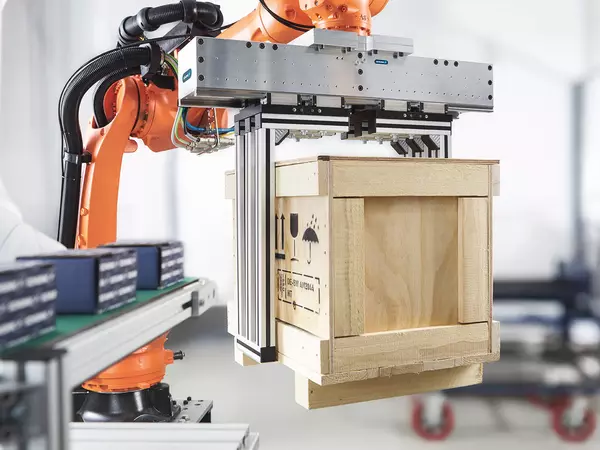

For handling large, heavy parts, SCHUNK offers two new configurable standard grippers the strengths of which lie primarily in the packaging, automotive, white goods or logistics industries. Users can choose either the PLG or the ELG, depending on whether they rely on pneumatics or electrics.

Pneumatic 2-finger parallel gripper PLG can be configured in less than 10 minutes. Its profiled rail guide enables the use of long gripper fingers, so it can effortlessly handle even voluminous workpieces from difficult-to-access transport containers with a gripping force of 2000 N in size 20 to 12,000 N in size 120. It is also suitable for challenging operating conditions such as high robot acceleration. Its large jaw stroke can be adjusted with millimeter precision from 100 mm to 400 mm. Users with high parts variation save here, because the PLG covers them with just one set of gripper fingers. In addition, it offers increased safety through optional integrated process monitoring. Due to an optional pre-mounted pressure maintenance valve, it reliably maintains the gripping position and force even in the event of a pressure failure. The powerful gripper is available in 5 sizes and offers a variety of possible applications owing to the numerous configurable extra features.

The electric long-stroke gripper ELG is the latest highlight among the configurable SCHUNK grippers. It covers a range of applications comparable to that of its pneumatic counterpart, but is actuated by an electric drive with a freely adaptable servomotor. The gripper can be finely adjusted and continuously positioned over the entire stroke from 100 to 400 mm. The cycle time in the handling process can be reduced by pre-positioning the fingers. It has a unique force-stroke ratio and offers an instantly available and controllable gripping force of up to 3,000 N in size 30 to 12,000 N in size 120.

Thanks to SCHUNK, the in-house design and production of workpiece-specific gripper fingers is no longer necessary. The design has become extremely simple due to new finger configurator FGR and not only saves 50% on costs, but also valuable time and resources. Eight standardized basic geometries ensure you find the right shape, which can be individually adapted to the requirements of the workpiece in the second step. The aluminum fingers can be combined with numerous SCHUNK electric and pneumatic grippers. Free customized labeling is available on top.

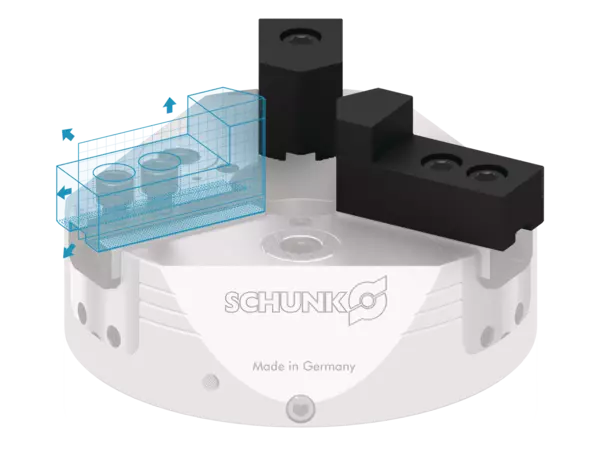

The new jaw configurator easyJAW offers over 500 different standard variants of top jaws. Those who cannot find what they are looking for in the world's largest chuck jaw program consisting of 1,200 jaw types can now effortlessly design their own soft top jaws, full grip jaws or monoblock jaws. The geometry, material, weight, interface and many other parameters can be customized in the online tool. Users thus have access to customized special chuck jaws in 1 to 3 weeks.

With the new planning tools, the application expert offers practical building blocks that take the customized solution path to a new level. After configuration, users have the option of downloading the planned solution directly in any CAD format, requesting an offer or ordering directly – always with transparent pricing and current delivery times. No more time-consuming in-house solutions and weeks of design time – thanks to the new SCHUNK configurators for grippers, gripper fingers and chuck jaws. schunk.com