With its ERT series, SCHUNK offers rotary units that are characterized by a particularly flat design while also enabling precise, flexible, and highly dynamic rotational movements. The unit can be used as a rotary table for components, assembly groups and tools, and can also be used as a rotary module in gantry solutions, as a rotary indexing table or a high-precision positioning module. The direct drive by a permanently excited torque motor ensures precise, highly dynamic movements. An absolute encoder that eliminates the need for a reference run ensures a repeat accuracy of 0.01°. Short response times and high torques are additional advantages offered by the ERT series. A large-dimensioned center bore allows the feeding through of cables and hoses, and even enables the use of a camera. Even when using an optional electric brake, which is controlled directly via the controller, the low overall height (up to 40% flatter than comparable units) remains unchanged. This makes the rotary units of the ERT series the top choice for compact assembly and handling applications.

The new ERT 100 size with a nominal torque of 16.7 Nm closes the gap between the established ERT models, which were previously available in the sizes 12, 50 and 300 with nominal torques of 1.5 Nm, 7.8 Nm and 32 Nm. At the same time, SCHUNK has further increased the variety of measuring system interfaces so that the modules can be combined even more flexibly with different drive controllers. With the HIPERFACE® and DRIVE-CLiQ interfaces, connection is made via two standardized plug connectors, separately for motor and encoder cable. One new feature is the HIPERFACE DSL® encoder interface, which combines all the advantages of a digital real-time interface. As a compact single-cable technology, it saves costs and is easy to implement – an enormous increase in efficiency and an important basis for Industry 4.0 applications. The path measuring system of the ERT rotary module works as a motor-feedback system for absolute measurement, single-turn version, with the HIPERFACE®, HIPERFACE DSL® and DRIVE-CLiQ interfaces.

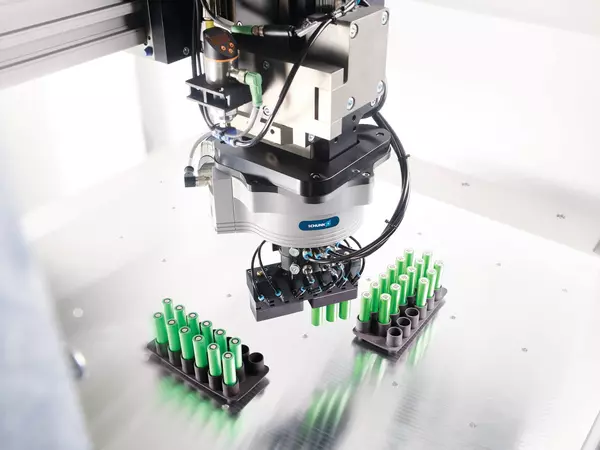

In addition to the electrical holding brake, SCHUNK makes available on request the optional higher IP54 protection class and UL certification according to US and Canadian regulations. The range of possible applications is immense. It extends from battery cell assembly and handling hairpins to stationary use as a rotary indexing table. Additional applications can be found in electronics, medical and laboratory technology, the pharmaceutical, cosmetics and solar industries, as well as in installation-space-optimized applications in mechanical engineering, in laser processing or packaging processes. Last but not least, SCHUNK provides its customers with the digital sizing assistant ERT via download for precise calculation and design of the swiveling times, once again proving itself to be an automation expert that provides comprehensive solution.