The days when fitness enthusiasts would disappear for hours into stuffy weight rooms to heave and press tons of iron plates are over. Modern “iron paradises“ look very different today. Sleek, smart circuit-training machines set the tone and have fundamentally transformed individual workout routines. Much has changed at Steinhart as well, ever since fitness has become a defining part of the business. “Our company once started with grave decorations and candle holders,“ says Patrick Genkinger, Manufacturing and Project Manager at Steinhart. His grandfather founded the company about seventy years ago in a garage and positioned it as a contract manufacturer for sheet and tube fabrication and wire bending. Today, Patrick Genkinger is co-shareholder and on track to join the management team as part of the third generation. “About twelve years ago, three students approached us with an idea: they wanted to make circuit-training fitness equipment,” Genkinger recounts. However, the three young men had only vague design ideas and just a modest investment budget. “But we did it!“ Steinhart promptly designed and manufactured six different machines within a few months. “The guys took the machines to the fitness trade show in Cologne and immediately sold 300 units.“ Since then, Hettingen-based Steinhart has been on a steep upward trajectory,” Patrick Genkinger confirms.

A new era had also begun for the Munich-based company EGYM, which the three students and originators eventually founded. Rising revenues, a rush on fitness clubs, home workout equipment – the industry was booming. This is how EGYM has become a global provider of intelligent, technology-supported workout solutions for fitness and health facilities and Steinhart manufactures these computer-controlled strength machines. They provide a holistic workout in 20 different versions. “These are high-tech training machines that automatically adapt to the user and offer various programs for different goals,” says Manuel Beck, Head of the Milling Department and Deputy Project Manager at Steinhart. He uses the machines himself and benefits from the fact that the automatic adjustments and various training methods result in an efficient, time-saving workout. “With rising production volumes, efficiency is also a primary goal in our manufacturing – one that we achieve through the right production components. That’s why we chose the SCHUNK modular system for automated machine loading,” affirms the Head of the Milling Department. “To clamp parts of different types, shapes, and sizes, we need workpiece clamping that is both flexible and efficient, Beck explains.

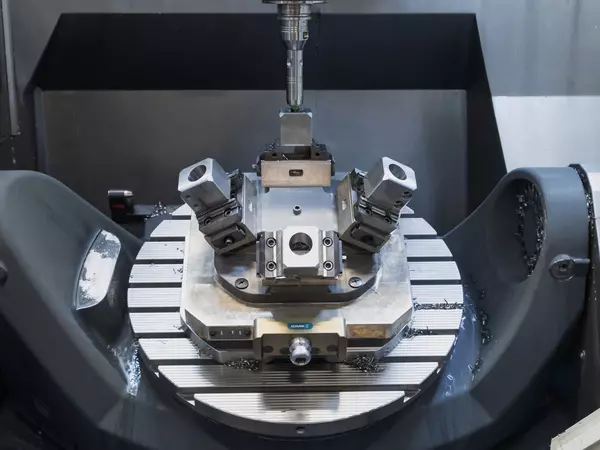

Steinhart opted for the modern DMU 75 monoBLOCK 5-axis milling center with a PH Cell 300 pallet automation system. Here, the VERO-S quick-change pallet system forms the basis for automated pallet changes. This flexible and precise machine table interface enables fast setup of all clamping components. At Steinhart, for example, SCHUNK KSM2 clamping rails with a jaw quick-change system are used. They allow clamping of large components up to multi-clamping of small parts. Moreover, Steinhart uses the KSC3 80 universal small parts clamping vise with stepped grip jaws. On the clamping pyramid, they deliver impressive component accessibility in combination with the TENDO Platinum toolholder and the TENDO SVL hydraulic clamping extension. “This modular clamping system is a practical solution,“ Manuel Beck confirms, “because, thanks to its versatility, it includes all the standard components we require for our tasks.” You won’t find that anywhere else.”

The pallet automation system is equipped with 24 storage positions. This modular, space-saving automation concept enables handling of various pallet sizes with a single, unified system. The separate setup station is used for ergonomic, main-time parallel setup of the pallets. Operators appreciate the convenient, easy control of the automation directly via the machine control panel. “This is the ideal solution for pallet handling in small batch sizes or single-part production,“ confirms Manuel Beck. For efficient machining, Steinhart also uses KSC-C2 5-axis vises with an adjustable clamping center and a jaw quick-change system. “We also highly value the magnetic clamping technology,“ the milling expert assures. “The MAGNOS magnetic chuck MFRS is a highlight for us because it requires only a brief electrical pulse for magnetization and demagnetization. No continuous power supply is necessary, which means optimal energy efficiency,“ says Beck.

“From day one, this pallet automation ran smoothly,“ summarizes Patrick Genkinger of working with the modular clamping system. “We installed VERO-S on the very first machine and have had no issues with SCHUNK products since, because they are very reliable," Genkinger assures. The optimization of machine uptime and the minimization of setup times have convinced the head of manufacturing. “We manufacture cost-effectively and at a high level of quality – both crucial aspects for high-priced, demanding end products,” says Genkinger. In addition to SCHUNK’s innovative products for automation solutions, he also highlights their competent, partnership-based consulting. Last but not least, he cites regionality and the proximity to the SCHUNK plant as a plus in collaboration. “Our manufacturing is absolutely fit with this clamping technology and delivers top performance,“ assures the future managing director. “We have grown with this modular system and will continue to grow in the future.“