Increasing variability, ever-smaller batch sizes, fluctuating demand, and growing global competitive pressure, along with issues such as the shortage of skilled workers due to demographic change, as well as the ongoing process optimization using current technologies, are just a few of the reasons why companies must increasingly consider automated loading and unloading of machine tools. We support you from the very beginning, ensuring that you understand and can make optimal use of the automated machine tending 101. What options are available? Which solution fits your manufacturing process? And what are the benefits of each approach? Together, we will find the right automation solution for you.

The automotive industry is facing a major upheaval – transitioning from the traditional combustion engine to E-Mobility. SCHUNK is your partner for E-Mobility and offers optimal concepts and solutions for the production, handling, and assembly of battery technologies and electric drive systems. With innovative handling technologies for hairpin stators, shafts and rotors as well as advanced methods for final assembly, SCHUNK makes a significant contribution to complete automation of the electric drive. These technologies and methods enable a smooth transition to e-mobility, and actively promote the dynamics of innovation.

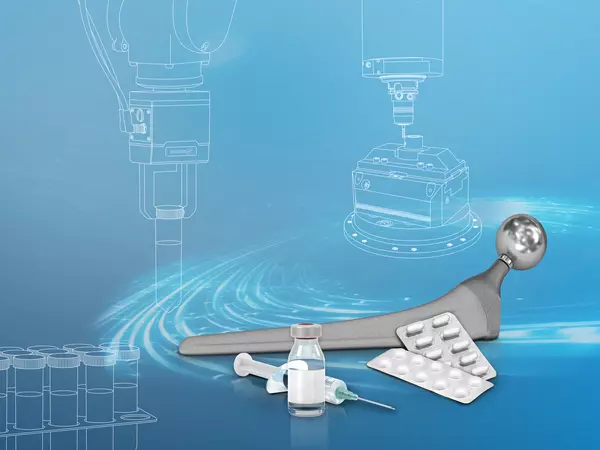

Standard and customized solutions are available for all your life science applications. The requirements of the life science sector cannot be compared with any other industry, and SCHUNK supports you in implementing your life science application. Residue-free, highly sensitive gripping, corrosion resistance and cleanroom suitability are just some of the many standard features that are required, and for good reasons. In addition to flexibility and precision, absolute process reliability is required in all types of life science applications.

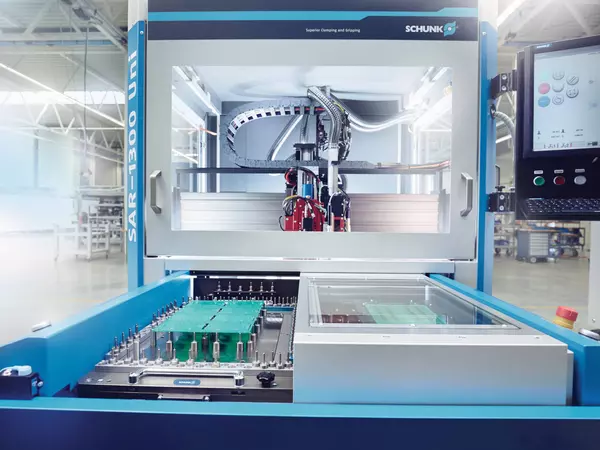

With advanced processes in electronic assembly group production, you will see systems and devices that meet the most demanding requirements resulting from increasing miniaturization, the use of highly sensitive components, and the rising quality demands for printed circuit boards.

Visit the SCHUNK booth to see first hand how fast, reliable, low-stress depaneling technology with maximum productivity could elevate your production.

Manufacturers constantly seek to optimize their processes through robotics, but for those new to automation, the first deployment can feel daunting. While the initial robot deployment is often the most challenging, true success comes from planning for future expansions. Automation, much like the machine tools it serves, should be seen as a long-term, flexible investment.

This presentation covers key considerations for automating machine tending and participants will explore practical strategies to boost productivity and reduce manual labor, with real-world examples ranging from simple cost-effective solutions to advanced complex applications.

Robots in machine tool operations often have idle time between cycles. Instead of letting them sit dormant, utilizing this downtime for secondary tasks—such as material removal—can significantly boost efficiency. This session dives into the world of automated material removal, covering what it is, why it's essential, and how to implement it effectively.

Attendees will gain insights into the benefits and challenges of robotic material removal and discover how different methods can be used to address workpiece defects. Real-world examples will highlight how automation can be successfully integrated and deployed to increase productivity and reduce human error, making material removal a more streamlined and effective process.