It is easier than ever to implement automated machine tending in your shop. Small and medium size manufacturers are discovering how simple automated processes achieve huge efficiency gains and cost savings.

In the SCHUNK booth at IMTS this year you will learn how automating your processes does not need to be complicated, or costly. If your company is looking to the future and wanting to remain economically successful – exploiting your productivity potential with automated processes is key.

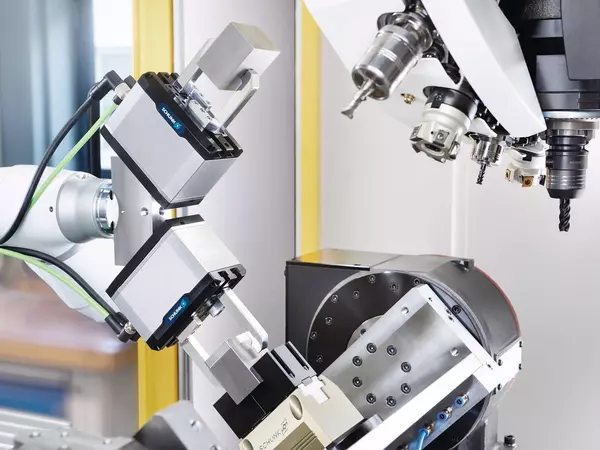

More than ever, efficient production requires the consideration of automated loading and dispatch of machine tools. Increasing variance, decreasing lot sizes, fluctuating demand, the skills shortage and increasing global competitive pressure, are only a few factors effecting the necessity to automate your machine loading. To stay efficient you must always be increasing the productivity of your machine tool and there are a variety of ways to do that – learn how you can optimize your production for maximum efficiency.

High productivity at low manufacturing costs and high factory quality are essential prerequisites for sustainability, profitability and competitiveness in your industry. Digitalization is considered to be the greatest challenge in the manufacturing industry. However, it also offers opportunities for companies to create efficient processes that are more precise and reliable. Find out how you can easily analyze and optimize processes with iTENDO² and what application possibilities the intelligent real-time sensor technology offers. From easy-to-use product configuration in just a few clicks, to analyzing data during the machining process to optimize and increase efficiency.

Almost 80 years of experience and expertise is at your fingertips. It is not always possible to fall back on a standard component. This is where SCHUNK Engineering comes in: From a simple adaptation to complex individual clamping or automation solutions that have to be developed from scratch, everything is possible. Partnering with SCHUNK means you working together with a team of experts with access to a global pool of knowledge and experience in designing the right solution for your unique application. In addition to a personal discussion with our customer service, our digital tools provide support for individual configuration: easyJAW (chuck jaws), easyToolholder (toolholder), FGR (gripper fingers), ELG and PLG as well as the linear module configurator.

The automotive industry is facing a major shift – transitioning from traditional internal combustion engines to electric-powered and hybrid systems. SCHUNK is your partner in e-mobility and offers optimal concepts and solutions for production, handling, and assembly of battery technologies and electric drive systems. With innovative handling technologies for hairpin stators, shafts and rotors as well as advanced methods for final assembly, SCHUNK makes a significant contribution to the full automation of the electric drive. These strategies enable a smooth transition to E-Mobility and actively promote the dynamics of innovation.

Manual machining of workpieces with hand tools is often associated with putting ergonomic strain on employees. In addition, health risks are often incurred due to fine particle emissions such as abrasive dust or chips. By shifting to automating your material removal processes these risks are minimized, and also creates even more values. With SCHUNK material removal tools, a large range of machining steps that used to be manually performed, such as deburring and grinding, can now be automated. The result: Higher productivity, consistent machining results, lower unit costs.