SRM 25-H-180-3-4P-6E-SI

Ident.-Nr. 1347283

- Angle of rotation: 180 °

- End position adjustability: 3 °

- End position damping: hydr. damper

- Torque: 4 Nm

- No. of fluid feed-throughs: 4

- Number of connectors for feeding through: 6

Technische Details

| Amortissement de la position finale | Amortisseur hydraulique |

|---|---|

| Angle de rotation [°] | 180 |

| Couple [Nm] | 4.0 |

| Nombre de positions intermédiaires | aucune |

| Indice de protection IP | 65 |

| Poids [kg] | 3.42 |

| Consommation de fluide (2x angle nominal) [cm³] | 84.0 |

| Pression d'utilisation nominale [bar] | 6.0 |

| Pression d'utilisation min. [bar] | 4.0 |

| Pression d'utilisation maximale [bar] | 6.5 |

| Diamètre de flexible à utiliser | 6 x 3.9 x 1.05 |

| Température ambiante mini. [°C] | 5.0 |

| Température ambiant maxi. [°C] | 60.0 |

| Catégorie salle blanche ISO 14644-1:2015 | 5 |

| Répétabilité [°] | 0.07 |

| Diamètre du passage au centre [mm] | 17.1 |

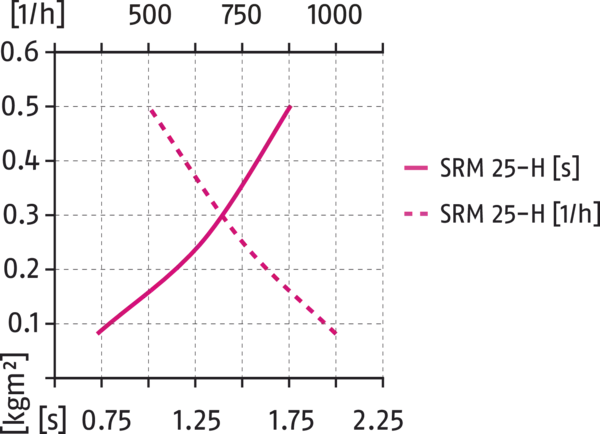

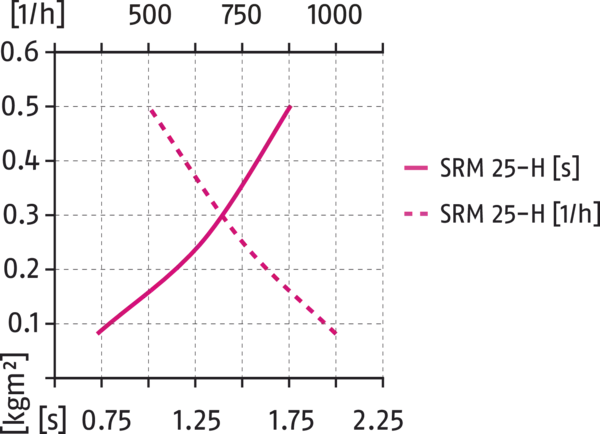

| moment d'inertie de masse maximum admissible [kgm²] | 0.5 |

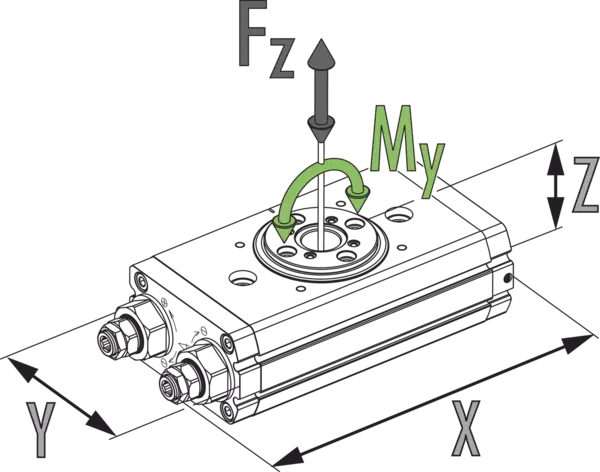

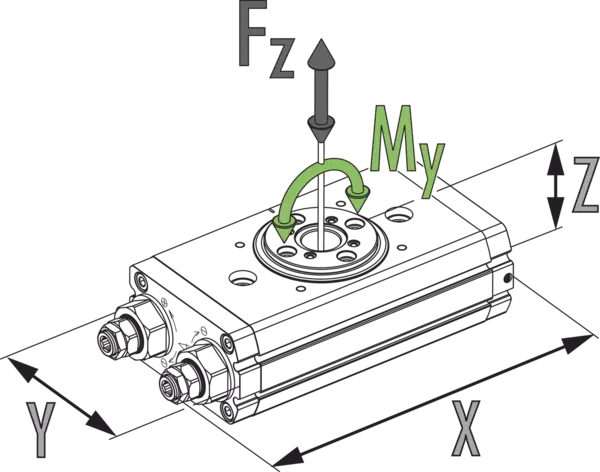

| Moment My max. [Nm] | 64.0 |

| Force axiale max. Fz max. [N] | 2250.0 |

| Nombre de passages de fluide | 4.0 |

| Pression min. dans le joint tournant [bar] | -0.8 |

| Pression max. passage pneumatique [bar] | 8.0 |

| Débit max. du passage pneumatique (à 6 bars) [l/min] | 140.0 |

| Nombre de connexion pour joints tournants | 6.0 |

| Taille des connecteurs (sortie) | 4xM8/3-polig2xM8/4-polig |

| Taille des connecteurs (entrée) | 6xM12/4-polig |

| Nombre de signaux | 20.0 |

| Tension max. [V] | 48.0 |

| Courant max. par contact [A] | 1.0 |

| Option pour détecteurs inductifs | Oui |

| La détection de position est réglable. | Oui |

| Version avec passages électriques | Oui |

| Version avec passage des fluides | Oui |

| Version pour détecteurs inductifs, réglable | Oui |

Dimensions et charges max.

Moment d'inertie admissible max. J*

Dimensions et charges max.

Les moments et les forces indiqués correspondent à des valeurs statiques, valables pour l'unité de base, et pouvant se produire simultanément. Le réglage de la vitesse par les limiteurs de débit doit être effectué pour s'assurer que le mouvement de rotation est réalisé sans impact ni rebond. Dans le cas contraire, la durée de vie peut être réduite.

Moment d'inertie admissible max. J*

- X-Achse:

- Temps de rotation

- Y-Achse:

- Moment d'inertie de masse

- X-Achse oben:

- Cycles par heure

General notes about the series

Repeat accuracy

is defined as a distribution of the end position for 100 consecutive cycles.

Pinion position

is always shown in the left end position. The pinion rotates from here to the right in clockwise direction. The arrow makes the direction of rotation clear.

Pinion screw connection diagram

When setting a swivel angle smaller than 90°, the left end stop must be completely turned in. This means that the left end position has a screw connection diagram on the pinion which is clockwise turned by 90° compared to the main view, which shows a swivel angle of 180°.

Customized angle of rotation

More swivel angles are available on request.

Torque in the end positions

Please note that the final angular degrees (approx. 2°) before the end position can only be approached using the force of a single drive piston. For this reason, double actuated modules only have about half the rated torque available in this area.

Travel to the pneumatic middle position

is carried out using only half of the nominal torque.

Swiveling time

is the rotation time of pinion/flange around the nominal rotation angle. Valve switching times, hose filling times, or PLC reaction times are not included and are to be considered when cycle times are calculated.

Standard conditions

The technical data shown refers to an environment of 20 °C and atmospheric pressure.

Housing material

Aluminum (extruded profile)

Actuation

pneumatic, with filtered compressed air as per ISO 8573-1:2010 [7:4:4].

Operating principle

Double piston rack and pinion principle

Scope of delivery

Swivel unit in the ordered variant, accessory kit (centering sleeves, O-rings for direction connection/detailed contents see operating manual) and safety information. Product-specific instructions can be downloaded at schunk.com/downloads-manuals.

Warranty

24 months

Service life characteristics

on request