Mechatronic grippers are masterpieces of technology and far more than just simple tools. They symbolize the impressive interplay of mechanics, electronics and integrated software and represent the progress achieved through the synergy of these three disciplines. Mechatronic grippers offer a number of advantages for the requirements of modern processes.

Mechatronic grippers are suitable for both mass production and batch production. Grippers with a short stroke are ideal for efficient mass production, while flexible gripper systems can be dynamically adapted to the varying requirements of batch production. This certainly does not rule out the use of flexible grippers in mass production. Rather, their adaptability can be used to further optimize the manufacturing process.

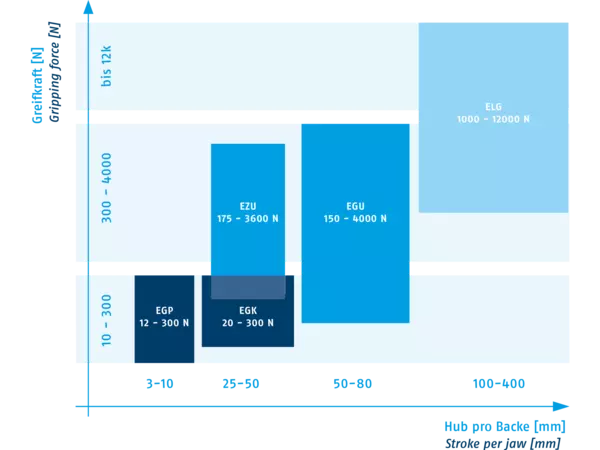

Our range of mechatronic grippers currently comprises five product series that are optimally adapted for use in various application areas in terms of gripping force and stroke.

They are used in a wide range of automated production processes, from machine loading and assembly to precision handling of a wide variety of workpieces.

For easy integration, the two new mechatronic grippers EGU and EGK are equipped with a variety of communication interfaces. This allows them to connect quickly and easily with all relevant robot and controller manufacturers.

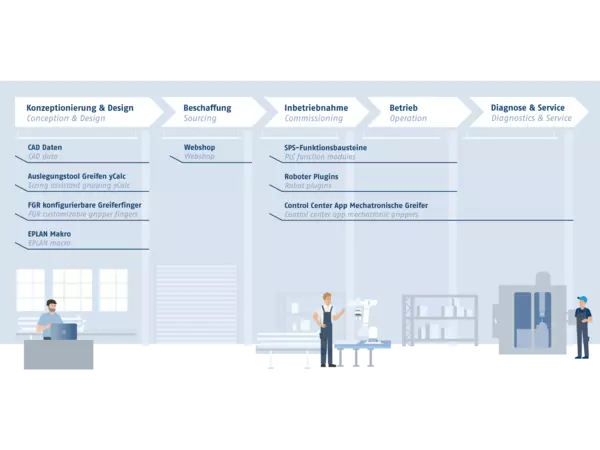

SCHUNK offers a wide range of digital tools and services for mechatronic grippers with the aim of providing the greatest possible support throughout the machine life cycle.