Your challenges are our drive: How can processes be more efficient, machines more productive, and production more sustainable? Together with you, we find answers and shape a healthy production for people, the environment and the economy.

Our expertise and broad portfolio make us a strong partner - today and tomorrow. But our focus is on the future: We rely on forward-thinking technologies and continuously develop solutions that drive your production.

We look forward to welcoming you personally to our booth and shaping the future together with you!

You will also find us in the Applications Park in Hall 6, Booth D51 focusing on battery cell handling.

We are looking forward to the personal exchange with you!

SCHUNK offers a strong portfolio of mechanical components. By adding sensor systems and electronics, the products become mechatronic systems – and thus smarter: They help make processes more efficient, safer, and sustainable, while providing valuable data for further process optimization.

Those who use automated machine tending have already taken an important step towards increasing their productivity. We support you right from the beginning, and ensure that you understand the Machine Tending 101 and that you can use it in the best possible way. Based on our many years of experience, we work with you to find the right type of automation for your process, increasing the productivity of your machine tool with a view to sustainability and the future. With our electrical and sensory products, we elevate them to a new level of efficiency by making data usable to optimize processes in a targeted way.

Collaboration with partners is important to us at all levels. SCHUNK is also open to technology in the software sector to drive automation forward. We support a variety of software solutions that function independently of specific platforms, operating systems or technologies, offering you maximum flexibility.

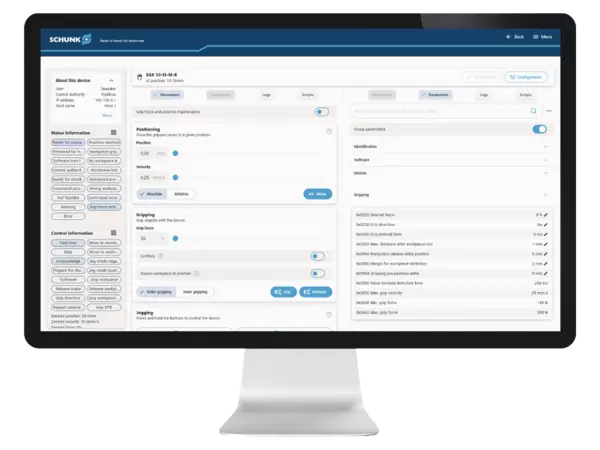

The SCHUNK Control Center is part of a central control platform that enables seamless integration and control of robots, gripping systems, and other automation components. Seamless integration into existing automation environments and support for multiple communication protocols make it extremely flexible. Because we rely on agnostic software, it can be used on different operating systems.

Providing our data for the ROS robot operating system also opens up new opportunities for you. The system makes it easier to program robots by providing pre-built modules for movement, sensors and communication. This makes it easier for different robot components to work together. ROS is used in both research and industry because it offers a number of open, free tools and a large developer community.

Digitalization is not only a significant trend; it is a crucial foundation for increased efficiency and faster process. We implement new technologies directly in practice to further develop our products in the Metaverse.

SCHUNK uses platforms such as NVIDIA, the worldwide leading provider of AI computing, to make its products available as digital twins for system simulation. SCHUNK is already working with NVIDIA to shape the development of new technologies and make its products available on the NVIDIA Omniverse platform.

A simulation created in ISG Virtuos can be transferred to Omniverse to remotely control a real machine or monitor its condition. This works if the twin is set up as HIL (hardware-in-the-loop), which means that it is controlled synchronously at the same cycle as the real machine. This means that various application scenarios can be simulated without actually having to set them up physically.

This collaboration is helping SCHUNK to develop and implement innovative technologies more quickly. An opportunity for you to optimize your development processes, quality and costs.

AI is not a distant future technology for SCHUNK. It is already seamlessly integrated into daily work, processes, products, and services. To stay at the forefront of innovation and actively shape this significatn key technology, SCHUNK is involved in pioneering networks and events in the field of AI, for example in the rapidly growing AI ecosystem IPAI in Heilbronn.

The vision-based Application Kit from SCHUNK consists of an application-specific selected gripper such as the EGU, a camera system and an industrial PC with pre-installed AI software. All components in the kit are precisely matched to each other and are process reliable. SCHUNK has developed the intelligent kit for a faster entry into autonomous handling of non-position-oriented objects. No prior knowledge of programming or image processing is required to use it. It frees skilled workers from repetitive tasks, creating a healthier and more attractive working environment. This also convinced the jury of the technology award. The HERMES AWARD was presented during the opening ceremony of Hannover Messe 2024.

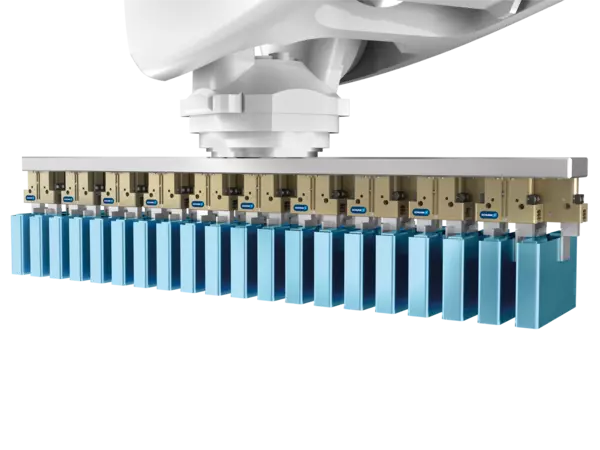

The Application Park in Hall 6, Booth D51, is a shared booth featuring several companies in the fields of robotics and automation. This year, for the first time, there will be a special exhibition on battery cell production in the field of e-mobility.

In addition to the production of high-performance battery cells, reliable and safe handling of energy storage systems in the subsequent process is also a key success factor for e-mobility. In partnership with FANUC, SCHUNK will be presenting a solution for the automated handling of prismatic battery cells. SCHUNK develops customized solutions for both handling the cells during assembly into battery packs, and for final assembly of the storage cells in the vehicle.

"At SCHUNK, our customers are at the heart of all our innovations. We complement physical components with digital solutions to meet customer needs and support efficient automation at every level – compatible with any ecosystem.

At Hannover Messe, we will showcase how, through intelligent technologies and connected applications, we not only increase productivity, but also ease reduce the burden on people and the environment. With our approach "Hand in hand for tomorrow,"' we focus on innovations that make a difference today and tomorrow – for our customers and the entire industry."