SRU-plus 25-H-90-3-4-M8-AS

ID 361707

- No. of fluid feed-throughs: 4

- Size of the E-connections on the output end: M8

- Torque: 4.6 Nm

Technical details

| Eindpositiedemping | Hydr. demper |

|---|---|

| Rotatie hoek [°] | 90 |

| Eindpositie kan worden afgesteld [°] | 3 |

| Koppel [Nm] | 4.6 |

| Aantal tussenposities | geen |

| IP-beschermklasse | 67 |

| Gewicht [kg] | 2.45 |

| Vloeistofverbruik (2 x nom. hoek) [cm³] | 60.0 |

| Nominale werkdruk [bar] | 6.0 |

| Min. werkdruk [bar] | 4.0 |

| Max. werkdruk [bar] | 8.0 |

| Diameter van verbindingsslang | 6 x 3.9 x 1.05 |

| Min. omgevingstemperatuur [°C] | 5.0 |

| Max. omgevingstemperatuur [°C] | 60.0 |

| Rondloopnauwkeurigheid [°] | 0.05 |

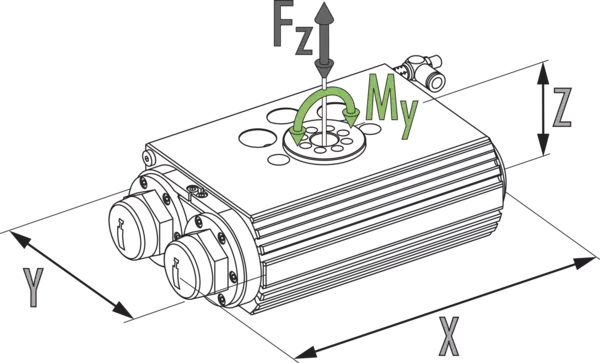

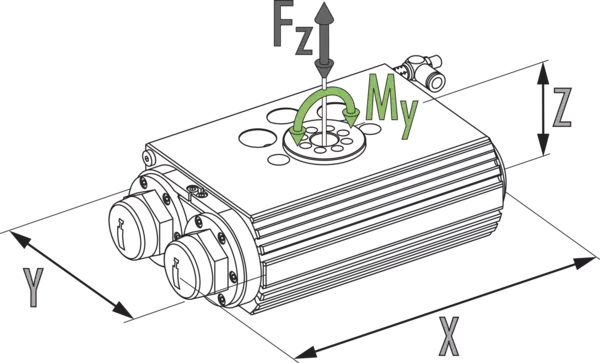

| Lengte X [mm] | 159.6 |

| Breedte Y [mm] | 86.0 |

| Hoogte Z [mm] | 129.0 |

| Moment My max. [Nm] | 10.4 |

| max. axiale kracht Fz max. [N] | 800.0 |

| Harde dempervariant | ja |

| Versie met vloeistofdoorvoer | ja |

| Versie met elektrische doorvoeren | ja |

| Versie met montageset | ja |

Afmetingen en maximaal toegelaten belasting

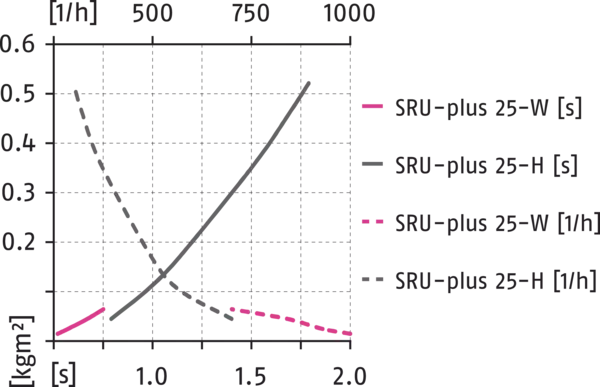

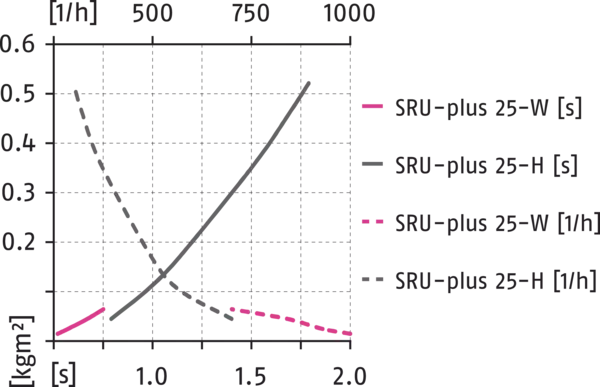

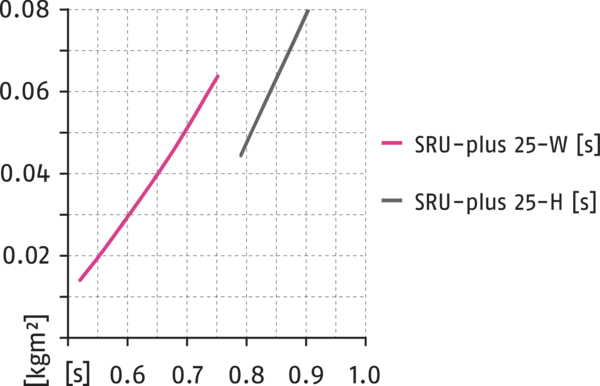

Max. toegestane traagheid J*

Max. toegestane traagheid J*

Afmetingen en maximaal toegelaten belasting

De opgegeven waarden voor moment en kracht zijn statische waarden en kunnen tegelijkertijd voorkomen. Er moet altijd zo worden gesmoord dat de rotatie zonder slag of stuiteren gebeurt. Anders wordt de levensduur korter.

Max. toegestane traagheid J*

- X-axis:

- Zwenktijd

- Y-axis:

- Massatraagheidsmoment

- X-axis top:

- Cycli per uur

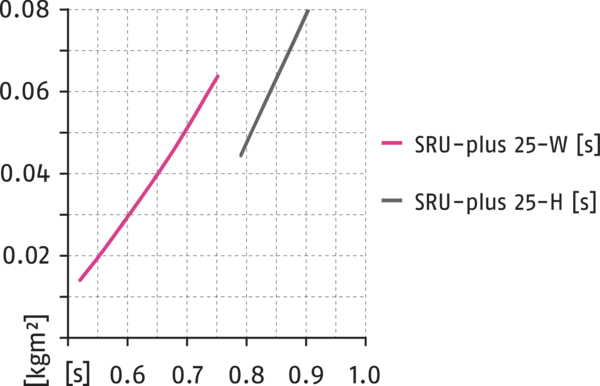

Max. toegestane traagheid J*

- X-axis:

- Zwenktijd

- Y-axis:

- Massatraagheidsmoment

- X-axis top:

- Cycli per uur

General notes about the series

Repeat accuracy

is defined as a distribution of the end position for 100 consecutive cycles.

Pinion position

is always shown in the left end position. The pinion rotates from here to the right in clockwise direction. The arrow makes the direction of rotation clear.

Pinion screw connection diagram

When setting a swivel angle smaller than 90°, the left end stop must be completely turned in. This means that the left end position has a screw connection diagram on the pinion which is clockwise turned by 90° compared to the main view, which shows a swivel angle of 180°.

Customized angle of rotation

More swivel angles are available on request.

Torque in the end positions

Please note that the final angular degrees (approx. 2°) before the end position can only be approached using the force of a single drive piston. For this reason, double actuated modules only have about half the rated torque available in this area. An external stop can be used to provide the full torque even in the end positions.

Travel to the pneumatic middle position

is carried out using only half of the nominal torque.

Swiveling time

is the rotation time of pinion/flange around the nominal rotation angle. Valve switching times, hose filling times, or PLC reaction times are not included and are to be considered when cycle times are calculated.

Standard conditions

The technical data shown refers to an environment of 20 °C and atmospheric pressure.

Housing material

Aluminum (extruded profile)

Actuation

pneumatic, with filtered compressed air as per ISO 8573-1:2010 [7:4:4].

Operating principle

Double piston rack and pinion principle

Scope of delivery

Flow control valves, centering bushings, O-rings for direct connection, fitting screws (SRU-plus 63 only), assembly and operating manual with manufacturer’s declaration

Warranty

24 months

Service life characteristics

on request