In the modern assembly industry, short cycle times, the handling of large quantities, and the handling of a variety of workpieces – from electronic components to large and heavy rotors – are of central importance. Thereby, the focus is always on ensuring process safety, reliability and system availability.

The extensive standard portfolio of grippers, linear axes, and swivel units enables flexible adaption to a wide range of requirements. In addition, SCHUNK offers the possibility of implementing individual special solutions to realize your assembly process.

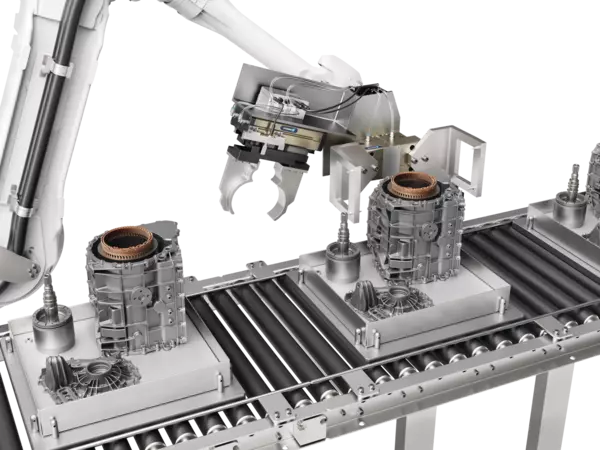

When joining individual components, precision and efficiency are paramount. Large quantities must be assembled with short cycle times. One specific example is an assembly line for an electric motor. The focus here is on special assembly steps. This includes precise handling of the stator housing in the joining station, inserting the stator into the corresponding housing and placing the rotor in the stator. Finally, the cover is installed, including the fitting.

High-performance assembly systems for mass production are characterized by short cycle times, high part output and uninterrupted around-the-clock operation. The systems comprise several assembly steps, whereby a zero-defect strategy is often supported by connected test steps. As a rule, transfer lines with workpiece carriers or, alternatively, rotary indexing tables are used to ensure an efficient production flow. Parts are supplied via feed belts, spiral conveyors or technologies for parts separation.

SCHUNK offers both pneumatic and pneumatic-free technologies to enable flexible and customized solutions.

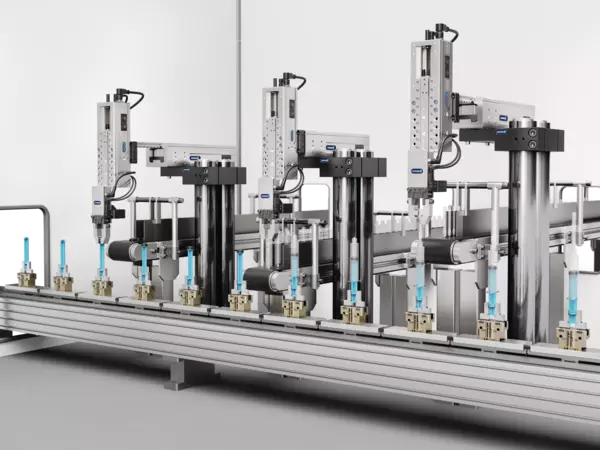

The automated assembly of O-rings increases the productivity rate of your production and takes the burden of monotonous tasks off employees. Our components enable precise mounting of O-rings, both on shafts (external assembly) and in bore holes (internal assembly). In this way, quality and efficiency can be optimized in equal measure.

In the application example, a semi-automated system is used due to the small batch size. The O-rings are fitted automatically by the ORG. Parts are supplied manually via the clamping plates. The PZN-plus centric gripper then picks up the component with the mounted O-ring and inserts it into the second component. The CMS quick-change system makes it possible for the system to be converted for other assembly jobs.

In CoLab, the SCHUNK Application Center, we work with you to test your planned application. We support you with feasibility studies, process analyses and demonstrations of your process. This way you can minimize your risk and save time during commissioning. Get in touch now with your SCHUNK consultant on site so we can discuss and develop your application.