Component manufacturing in prototype construction comes with specific requirements. High flexibility and easy adaptability of the production environment are essential to enable iterative improvements in the design and functionality of the component. “We work with sample parts and small batch sizes, which means we constantly need to implement new clamping situations – as quickly and safely as possible,” explains Darius Adamski, Application Engineer CAD-CAM at Vitronic Machine Vision. In the prototype construction department of the manufacturer of image recognition and image processing systems at the Wiesbaden site, housing parts, brackets, heat sinks, mounts, and other components for the interior of state-of-the-art optical testing and inspection systems are produced. Vitronic’s devices are high-tech products that require conventional assembly manufacturing and high-level machining processes. “Our machine equipment has to be first-class – broad and flexible enough to allow us to react quickly and work efficiently,” Adamski emphasizes. “Our approach is not comparable to series production. On the one hand, we need different options for clamping and machining. On the other hand, safety in constantly changing situations is a major concern to avoid damage.”

The solution to these requirements was found by Darius Adamski and his team in 2018 during a visit to the AMB trade show. “That trade show visit was a huge surprise for us,” the Project Manager emphasizes. “At the SCHUNK booth, we immediately saw that this was exactly what we needed.” The wide range of clamping devices with every conceivable variant convinced Adamski. “No one else offers anything like this!” Until then, he had worked with several different suppliers and contacts for toolholders and clamping devices, which meant long processes and a lot of time spent on coordination. “That had to stop, because it was absolutely inefficient. We finally wanted a central point of contact and a direct partner for our machine equipment. We found that at SCHUNK – and not only that: we now have access to an unprecedented wealth of modules.”

This marked the beginning of a forward-looking collaboration. In 2019, Vitronic equipped its newly acquired five-axis machining center Alzmetall GS 800 with various modules from SCHUNK’s clamping technology toolbox – including the VERO-S NSE3 138 quick-change pallet system, different vises and lathe chucks, as well as the TENDO EC and TENDO Slim 4ax toolholders. Since then, flexibility, setup time optimization, ease of handling, and efficiency have reached a new level. “This variety of clamping devices and jaws has taken our work to the next level. The comprehensive SCHUNK modular system is exactly what we need,” Adamski assures. And above all, he emphasizes: “The quality is spot on.”

At the beginning of 2025, another machine investment followed – a high-performance machining center from the Tiltenta series by Hedelius. Its large working area with an infinitely swiveling milling head enables vertical machining of long workpieces. The integrated NC rotary table also allows five-side machining of heavy-duty parts. Thanks to a partition wall, both a three-axis and a five-axis workspace are created, enabling efficient pendulum operation. “For the new machine, we simply copied the setup of the Alzmetall,” reports Lukas Seibel, Machining Technician and Application Engineer CAD-CAM at Vitronic Machine Vision. “We were thrilled to see how easily we could transfer the clamping modules from one machine to another. For us, this means short processes, fast setup times, and ergonomic handling. We can respond immediately to new situations in our daily work. With this adaptable and scalable machine setup and the interplay of both systems, our machining efficiency has received a significant boost,” the young machining technician enthuses.

The modular VERO-S quick-change pallet system also serves as the toolbox foundation and precision interface to the machine table on the new Hedelius Tiltenta. “With this system, we achieve precise clamping of a wide variety of workpiece geometries and can set up quickly and efficiently,” emphasizes Lukas Seibel. With a total of 18 installed NSE3-138 modules, the prototype department at Vitronic achieves full machine utilization. The stainless steel, sealed modules are equipped with a spring-actuated cone closure that automatically locks the changing interface as soon as the clamping pin is lifted. This prevents chips or dirt from entering. As a result, process reliability in machining operations as well as the durability of the clamping station are ensured. The dimensionally stable clamping modules can absorb high tilting moments and transverse forces, resulting in extremely rigid, vibration-free clamping. In addition, the pneumatic NSE3 modules achieve high pull-in forces, which remain fully effective even in the event of a pressure drop.

At the VERO-S clamping station, Vitronic uses various clamping modules from the SCHUNK modular system, such as the KSC3 125-300 basic clamping vise with console or the slim five-axis vise KONTEC KSX-C2 125-300. Setups in combination with the VERO-S take only seconds. SCHUNK has set a new milestone with the fully sealed and robust KSX-C2 clamping force block – offering even more flexibility, shorter setup times, and secure holding. Jaw changes are tool-free. With a 130-millimeter basic clamping stroke and reversible jaws to expand the clamping range, the vise can be quickly adapted to a new range of workpieces. A wide variety of quick-change jaws are available. Thanks to the active pull-down mechanism, precise six-sided machining on the five-axis machine is possible. Users achieve excellent results in terms of flatness and perpendicularity. The upward-tapered outer contour of the KSX-C2 ensures good accessibility with standard tools. Operators can adjust the clamping forces continuously using a torque wrench, for example to apply precise forces when clamping delicate parts. During machining, an integrated elastomer damping system absorbs vibrations – resulting in a high surface quality of the workpieces.

The ROTA-S plus 160 2.0 manual lathe chuck is also a part of the modular clamping technology system at Vitronic. SCHUNK has designed the lathe chuck for various clamping tasks as a 2- and 3-jaw chuck, particularly for clamping round workpieces. The high performance of the wedge bar system and the optimized lubrication ensure process-reliable clamping and continuously high clamping forces; providing users with enhanced machining efficiency. The designers pulled out all the stops in developing the ROTA-S plus 2.0: a large through-hole, base jaws with angled serration, a user-friendly jaw quick-change system with high repeat accuracy, fully hardened and ground functional parts, as well as visual safety features for maximum operational safety.

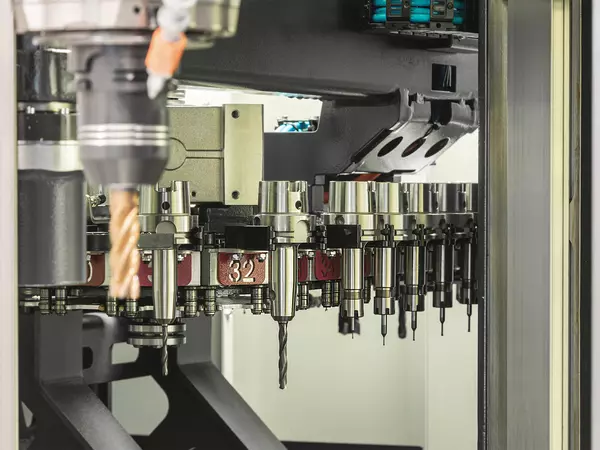

“New to us were the toolholders with hydro-expansion clamping technology,” states Darius Adamski. The Project Manager had initially considered conventional heat-shrinking toolholders for the Alzmetall GS 800, newly acquired in 2019, but he was quickly convinced by the hydro-expansion technology of the TENDO series. Tool clamping is achieved via a hydraulic mechanism, in which turning a screw compresses the internal pressure medium, and elastically deforms the expansion sleeve. This firmly encloses the tool shank. The high clamping force and radial stiffness ensure absolutely safe hold of the tool and precise run-out. As the inventor and market leader in hydro-expansion clamping technology, SCHUNK has more than 40 years of experience in this field. Thanks to application-specific segmentation of the toolholders, customers can select the appropriate hydro-expansion toolholder variants depending on their application and requirements. Vitronic uses the TENDO EC and TENDO Slim 4ax models.

Users of hydro-expansion technology have appreciated for decades the economical, efficient, and resource-saving machining of parts. These toolholders come standard with fine balancing and are suitable for high rotational speeds. The tool shanks can be clamped directly into the toolholder – allowing the TENDO series to offer a tool change that is both micrometer-precise and completed in seconds. Operators save setup time and can dispense with additional peripheral devices. They benefit from high flexibility, as both direct clamping and clamping of different diameters with slotted or coolant-tight intermediate sleeves are possible. The consistently precise run-out and effective vibration damping ensure long tool life for the metalworker.

“Discovering the versatile SCHUNK modular system at the trade show in 20 18 was a stroke of luck for us,” confirms Darius Adamski. “The clamping modules and toolholders have proven to be real time-savers. On top of that, we have gained significantly in reliability, efficiency, and ergonomics.” Furthermore, the functionality of the products has always been assured, and problems, or the need for repairs have never occurred. Adamski and Lukas Seibel plan to equip the next machine with the SCHUNK modular system as well. First, the five-axis SEP pyramid will be installed on both the Hedelius Tiltenta and the Alzmetall GS 800, which will be fitted with KSC3 125-160 vises. The multi-clamping in pyramid configuration allows several workpieces to be clamped simultaneously, further reducing setup times. “If we have questions, a single phone call is enough,” assures Adamski, concluding: “Complete system, flawless communication, nothing left to wish for. We really value such collaboration – and now we have everything from a single source!”