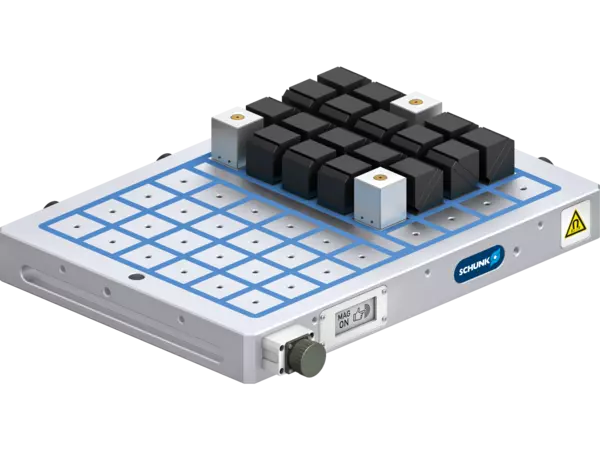

For years, MAGNOS magnetic chucks from SCHUNK have stood for energy-efficient and reliable clamping of ferromagnetic workpieces. Workpiece clamping with magnetic clamping technology not only has impressive and high holding forces, it is also the ideal clamping solution for milling applications with 5-sided workpiece machining in a single set-up. Electro-permanent technology guarantees a uniform magnetic clamping force over the entire workpiece, making even complex machining tasks possible. Here, the plates only require a short electrical pulse for magnetization or demagnetization, which contributes to energy-saving machining processes.

SCHUNK was the first supplier to equip its magnetic chucks with a visual status display in the connection housing. The green/red colors provided the machine operator with information about the magnetization status. With the revision, the toolholding and workholding experts have now replaced this safety feature with an ePaper display that is unique on the market, even more clearly displaying the clamping statuses "MAG ON" and "MAG OFF".

In conjunction with the SCHUNK MAGNOS app, the status display makes handling MAGNOS magnetic chucks much easier, thereby ensuring maximum process reliability. The app can be used to quickly and easily calculate holding forces in advance based on the size and material of the workpiece. As the process data is also fully included in the calculation, production processes can be optimized. The app uses a simulation to display whether all parameters have been correctly selected for safe machining, eliminating any uncertainties.

MAGNOS MFRS magnetic chucks with the new ePaper status display will be available from the first quarter of 2025. The MFPS and MFRS-DM series are currently being equipped.