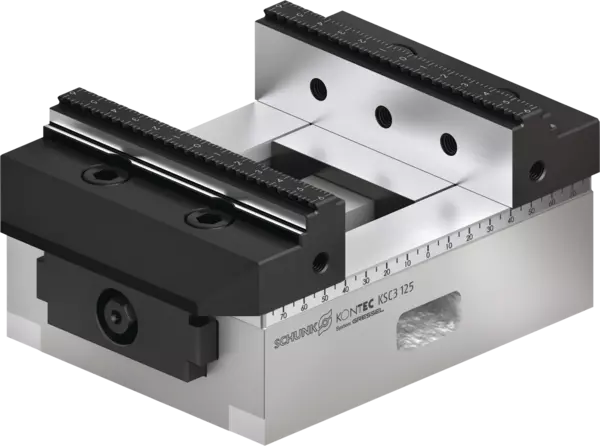

KSC

Basic clamping vise

This product has been discontinued and is no longer available.

Phased out date: Jun 30, 2023

Alternative products:

The SCHUNK KONTEC KSC centric clamping device is an all-rounder for stationary workholdings. From conventional clamping and small clamping depths to 5-sided machining, molded parts, plates and saw cuts: the SCHUNK KONTEC KSC can be adapted with just a few quick steps.

Description

Advantages – Your benefits

- Extremely flat design

For maximum utilization of the machine room - Spindle encapsulated

Dirt-resistant and low-maintenance clamping devices - High clamping forces

Ensure process reliability during machining - Large clamping range

High level of flexibility - Lateral drainage slots

For drainage of coolant and chips - Ball bearing mounted, clearance-free spindle

For maximum repeat accuracies of < ±0.01 mm (KSC 80 & 125)/±0.015 mm (KSC 160) - Wide range of applications

Suitable for rough and finished parts machining - Wide jaw program

Optimal adaptation to new clamping tasks - Optimum jaw support for O.D. and I.D. clamping due to a very long base jaw guidance

Allows high clamping forces at a long service life - Clamping by tension

No bending of base body - VERO-S interface

Versatile range of combinations thanks to the VERO-S modular system for even shorter set-up times.

Options and special information

- Maximum precision and process reliability

Due to its extremely flat design, the manual centric vise from SCHUNK ensures high precision and clamping forces. A pre-tensioned and backlash-free center bearing and an extra fitted slide ensure a repeat accuracy of up to ±0.01 mm and enable a precise rough and finished part machining in only one clamping system. - An integrated chip drainage and a specially protected spindle provide maximum process safety. The centric clamping vise is also ideal for storage solutions for automated machine tools: the attractively priced solution can be used with any type of pallet storage.