Linear direct axis SLD

The dynamic axis all-rounder

perfectly tailored to your application

The SLD series is a new generation of SCHUNK linear direct axes. The dynamic, heavy-duty axes with electric linear direct drive ensure short cycle times and more productivity in high-speed assembly and handling processes. Due to the high driving forces up to a maximum of 2.4 kN and the load rating of up to 276 kN with the heavy-duty version as well as the long service life, the axis is ideally suited for any industry – even for demanding cell production in the dry room.

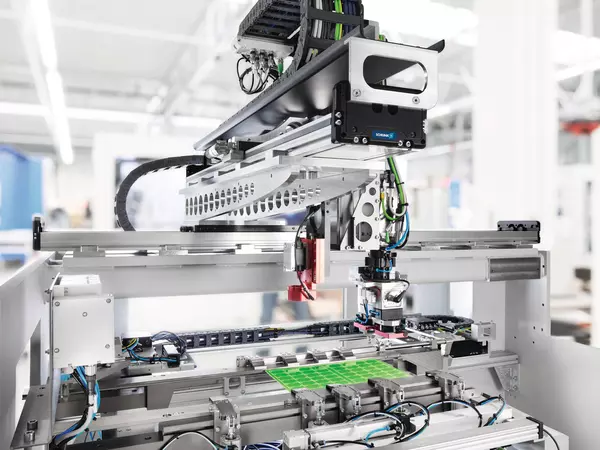

SLD in cell production

Advantages – Your benefit

- Almost no wear parts

for long service life and reliability of the system - No mechanical play between the drive components,

for fast responsing mode and high positioning accuracy - High basic load ratings

for high bearing load capacity and long service life – especially in the heavy-duty version - Integrated motor and measuring system in the axis

minimizes interfering contours and space requirement - Can be fitted with absolute path measuring system

less programming effort and time saving when commissioning and in operation - High dynamics for shorter cycle times

therefore a high productivity is achieved - UL certification

for use in the US and Canadian markets - Optional pneumatic safety holding brake as rod lock

for high requirements on machines and personal safety - Optionally certified safety devices according to SIL2/PLd

for applications that place increased requirements on machine safety - Application-specific axis

through diverse variants and options and individual configuration

Options and special information

- Modular encoder system

The linear module is available with different path measuring systems. The incremental path measuring system has a 1Vss interface. The absolute path measuring systems are optionally available with the HIPERFACE®, HIPERFACE DSL®, DRIVE-CLiQ or EnDat 2.2 interfaces. Other interfaces are available on request. - Pneumatic holding brake

The linear module is optionally equipped with a safety holding brake. This holding brake is pneumatically actuated. Its function is activated in a non-ventilated state. The holding brake is used to maintain the position of the linear axis in a currentless condition. The holding brake is also suitable for applications in the field of machine safety. Please feel free to contact us. - Further motor slides

The linear axis can be equipped with multiple active motor slides. This allows special designs and customized axis solutions. - Certified encoder system

All encoder systems are certified according to SIL2/PLd. This means that even demanding applications with high requirements in the area of machine safety can be implemented. Please contact us. - Version with food -compliant lubrication (H1G)

Available on request as an easy entry solution for medical technology, lab automation, the pharmaceutical and food industry The requirements of EN 1672-2:2020 are not fully met. - Version with increased number of days/longer service life

The SLD axis is available in a heavy-duty version from size SLD 22 and up for applications with increased requirements in terms of basic load ratings, rigidity and lubrication intervals. - High speed variant

Based on the heavy-duty version, a high-speed variant with speeds of up to 10 m/s is available.