Making its customers' processes understandable, simple and efficient is the declared goal of automation specialist SCHUNK. Data transparency plays an important role here. It enables reliable processes and provides the basis for resource-efficient planning, zero-defect production and energy efficiency. That is why the digitalization of components and processes goes hand-in-hand with sustainable manufacturing. SCHUNK shows how digital solutions lead to greater efficiency and lower resource consumption with practical examples from automated production in a wide range of application areas.

In Munich, SCHUNK will be showing a whole range of new efficiency bringers. Among other things, the PPD positioning unit will be making its debut. It now enables more complex motion sequences in pneumatic handling as well. In conjunction with pneumatic grippers, gripper fingers can be controlled flexibly and with high precision, and gripping force and speed can be regulated. Required application parameters for defined gripper series are already stored on the unit – this saves time during commissioning. Combined with the powerful, pneumatic universal gripper PGL-plus-P with extra-long stroke, versatile handling tasks can be realized even in demanding environments, from machine loading to highly sensitive cleanroom applications. SCHUNK is offering the pneumatic gripper as the world's first to have GripGuard certified secure gripping force maintenance. In addition, it has an already integrated IO-Link sensor system that enables position sensing of the gripper fingers and thus saves on external sensors.

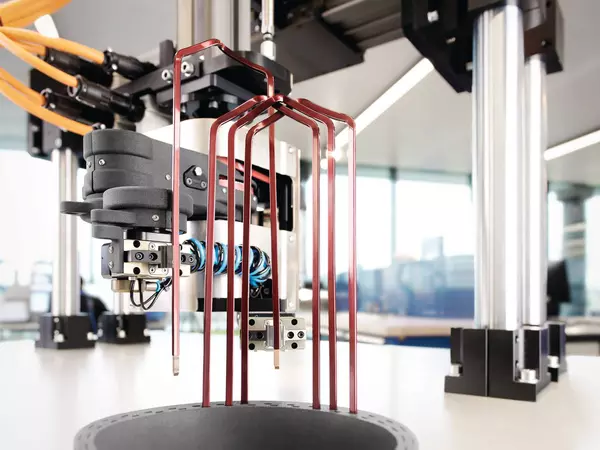

Two new electric grippers set standards in terms of flexibility, interface diversity and process reliability: The smart universal gripper EGU shows its strengths to the full in multi-variant machine loading, even under harsh conditions. With its large stroke and integrated gripping force retention, it is able to reliably load and unload rough and finished parts of different sizes. It can be freely networked. The integrated gripping force maintenance and a StrongGrip mode for increased gripping force makes it a reliable all-rounder for all handling tasks. Its counterpart for handling delicate, fragile parts in cleanroom areas is the smart gripper for small components EGK. With its SoftGrip mode, it masters demanding and varied handling tasks in the laboratory industry or electronics manufacturing. SCHUNK offers both grippers with extensive function modules and commissioning plug-ins.

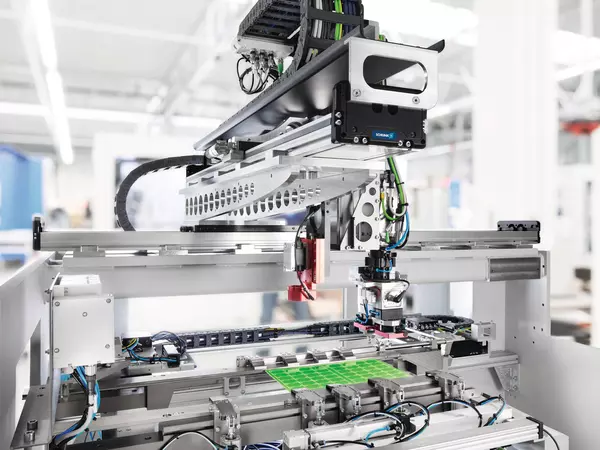

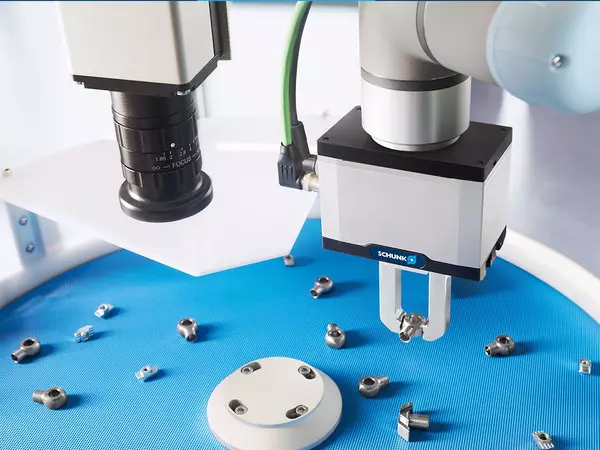

SCHUNK has developed the user-friendly 2D Grasping Kit for handling individual objects randomly arranged on a single level, which makes it much easier to get started with automated object handling. The core of this intelligent system is the in-house developed AI software, which is pre-installed on SCHUNK's own industrial PC (SVC). Since the market launch in 2022, the automation expert has further optimized the software and simplified the teaching and labeling of components. This coordinated complete package of hardware, software and service comes from one source and can be used for all robots.

SCHUNK will be presenting the dynamic linear direct axes SLD for the first time. The profiled rail guide and compact design, they can handle higher load capacities and have a long service life. Heavy-duty axes with electric linear direct drive, users achieve increased productivity in high-speed assembly and handling processes due to the short cycle times.

The new flat ERT rotary units are also equipped with direct drive and offer a wide range of measuring system interfaces such as the HIPERFACE DSL® digital real-time interface and an electric holding brake. The unit can be used as a rotary table for components, assembly groups and tools, and can also be used as a rotary module in gantry solutions, as a rotary indexing table or a precise positioning module.

In order to successfully counter the shortage of skilled workers and pressure for efficiency and to accompany the change to digital, more sustainable manufacturing processes, the application expert offers a variety of automation approaches from a single source. Using specific examples, SCHUNK will demonstrate automation solutions for new, easy-to-integrate manufacturing and assembly processes that meet the requirements for precision, dynamics and reliability in different industries such as e-mobility and life science.

SCHUNK at automatica 2023: Hall A5, Booth 502