Mack-Alusysteme is located in Klettgau-Geißlingen, the southern part of Germany and manufactures high-precision components for their customers in the aerospace, rail transportation, electronics, automotive and mechanical engineering industries. "We manufacture special, customized premium products and construction parts for the high demands from extruded aluminum profiles, or sheet material," explains Dominik Isele, Production Manager at Mack-Alusysteme. "Our portfolio ranges from high-precision processing to exclusive products from very small to eight meters in length, including surface treatment on request. For these individual solutions, we are using our high technical standards in both module production and component assembly. For us the precision of every hundredth is curcia," emphasizes Isele.

The Production Manager at Mack knows aluminum processing from the ground up. He was trained here and has qualified for this responsible management position over the years. "Where others stop with precision, this is where we start," says Isele, describing the high standards at Mack. "For our international customers from the premium sector, for example, we manufacture decorative and furnishing elements for high-priced cabin interiors. Every micron must fit perfectly. To achieve this, we rely on modern machinery for CNC machining. To meet these high customer requirements, we need first-class top performers as partners, but also absolutely reliable production components." For some months now, Mack’s flagships have included the DMU 95 monoblock PH Cell 300 five-axis milling center for modular pallet handling. The heart of the fully automatic component machining is the VERO-S quick-change pallet system from SCHUNK, which serves as pallet changing unit on the machine, as a robot coupling, and is used for direct workpiece clamping. Thanks to the modularity of the VERO-S system and its flexible functionalities, the quick-change pallet system can take over several tasks.

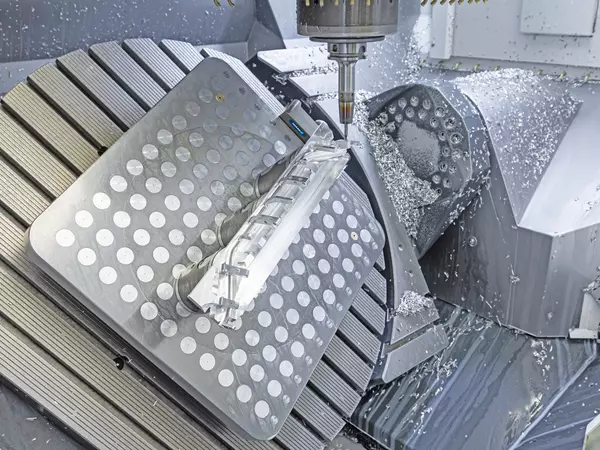

"With the new machine, we wanted to find a solution that would allow us to design the pallets flexibly and cover many different components with just one device," says Isele, explaining the initial situation. The new machine presented several challenges for Mack: Due to its complex geometry, the machine works on a part for a long time. It should therefore be possible to prepare unmachined parts in such a way that a stock of fully clamped parts is created that can be automatically processed in a series of successive stages. The machine can be utilized 24/7 with pallets that are pre-equipped in the pallet station, waiting to be processed and are placed here again after processing. "Our aim was to maximize the spindle running time, and to fully automate the pallet infeed and outfeed," confirms Isele. Mack has achieved this goal with the VERO-S clamping system from SCHUNK. And not only. "because the machine is a 5-axis machining center and large-volume aluminum profiles have to be machined from 5 sides, we needed a solution for excellent accessibility to the component. The WDM-5-X direct workpiece clamping system has proven its worth for this clamping task."

With the clamping modules WDM-5-X from the modular VERO-S system, the user can set up clamping pillars according to specific requirements, and thus achieving optimal workpiece accessibility during five-sided machining. An interfering contour is avoided with this direct workpiece clamping method and thte spindle reaches every component position. This principle of pillar clamping makes it possible to introuce cut-outs accross the entire workpiece. The WDM-5 X basic modules serve as a foundation for setting up on a pallet, and combined with freely combinable stacking modules in various heights, various machining heights can be implemented. The workpiece to be machined, is connected to the clamping pillar with a clamping pin via the pallet. Actuation is carried out medium-free and manually with a tightening torque of 15 Nm. The type of fastening depends on the workpiece weight and the metal cutting process, which is why SCHUNK offers a multitude of pins in its portfolio. Mack uses the dovetail pin,with a depth of only 3.5 mm in the raw material and without interfering contours.

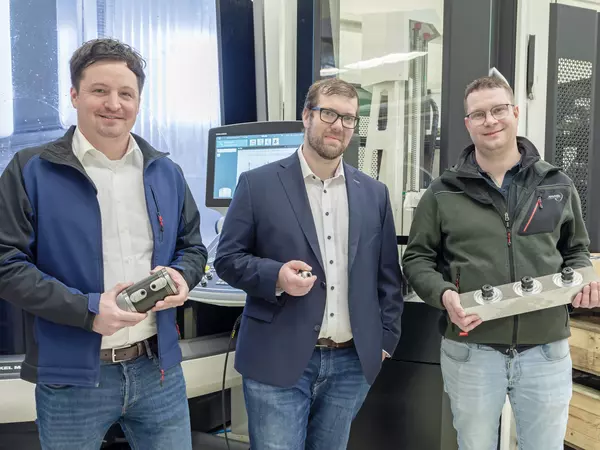

"In the past, we had to manage it with intermediate tables for classic vise clamping to achieve the necessary stroke for five-sided machining. This is a thing of the past now," Dominik Isele confirms. "With this clamping system we are able to cover all tasks on the machine." SCHUNK initially provided the WDM-5 X system to the Production Manager for testing purposes. "Our special design department deals intensively with any specific customer application," says Rainer Storz, Technical Consultant for Stationary Workholding at SCHUNK. "Based on the customer's framework conditions, our designers will find the best possible solution thanks to their sound knowledge and profound application experience in joint coordination. We are bringing in our complete know-how long before the customer places the order," says Storz. This is how a proposal for an optimal result is finally achieved.

This happened at Mack within a very short time because the Production Manager was able to precisely outline the tasks of the clamping system. "What absolutely convinced us that this system fits, was the clamping pin on the workpiece in dovetail design," summarizes Isele. The SCHUNK dovetail pin allows direct clamping of flat workpieces, which have a clamping depth of just 3.5 millimeters. The trapezoidal shape of the dovetail joint significantly increases the contact surface through which clamping forces are absorbed. This enables a lower clamping depth and a force-fit connection. "It saves raw material. Moreover, we were able to keep our previous blanks, which are clamped with different vises one-to-one and did not have to make any changes when ordering materials. Due to the excellent accessibility in five-sided machining with the WDM 5-X pillars, these two advantages became an unbeatable argument for the system."

Dovetail pins offer new possibilities in machining thin workpieces, mold halves or freeform parts. In metal cutting as well as in the tool and mold making. Conventional quick-change pallet pins require a screw-in depth of 20 to 25 millimeters – here it is only 3.5 millimeters. The required interface can be easily manufactured with a freeform milling cutter with minimum material removal. Then, the clamping pin is inserted and locked by means of a hexagon socket key via two hardened clamping slides. After machining, the clamping pin can be removed again and used for other purposes.

The operator sets up the pallets with the WDM-5 X modules and the blanks at a separate and ergonomically designed set-up station. Mack uses 12 VERO-S pallets measuring 500 x 500 millimeters; the pallet storage unit of the DMU 95 monoblock PH Cell 300 is designed for a maximum of 28 pallets and can be individually configured with different compartments and levels. The clamping positions on the pallet are clearly marked thanks to a grid. and depending on the workpiece, reliably repeatable clamping plans can be used. Due to the easy handling of the clamping modules and the precise clamping plans, even non-skilled workers can carry out the manual set-up process. Finally, the robot collects the pallet with the fully clamped workpieces from the set-up station and stores them in the pallet station so that they can be fed into the machine at the appropriate time and retrieve them from there again after processing.

The VERO-S NSR 160 robot coupling is the interface between the workpiece pallet and the robot. Thanks to the slim design, pallet loading could be done close to the machine table. The high pull-down force on the robot-side clamping pin creates a rigid system with a high holding force even at high torques. This makes handling of heavy pallets simple and process reliable. The clamping process of the robot module takes place via an integrated spring assembly. The spring force is converted into a high pull-down force on the clamping pin via an axial piston and patented drive kinematics. Clamping via two clamping slides is form-fit and self-locking; even in the event of a pressure drop, the full pull-down force is maintained and can be further increased via a turbo function integrated as standard. The anti-rotation pretection around the central longitudinal axis is provided either by slateral bevels or by two cylindrical pins in the front. Entry radii on the clamping pin and clamping module enable quick and safe joining, even with a tilt angle and eccentricity, and therefore inaccuracies of the robot are compensated. The module is opened pneumatically with a system pressure of six bar. The completely sealed modules are rustproof. Thanks to the use of a high-strength aluminum alloy, the VERO-S NSR 160 has a low weight, in favor of maximum pallet load capacity. A total transfer weight of 300 kilograms – workpiece and pallet including robot coupling – is possible.

The robot exchanges the pre-equipped pallet on the machine table fully automatically. At Mack, the individual modules of type VERO-S NSE3 138 are installed on the machine table. It is currently the most powerful pneumatic quick-change pallet system for universal milling operations. The pallet is pulled in simultaneously at the four clamping pins. After processing, the pallet is released, temporarily stored in the pallet station, and a new processing job is started. Controlling the automation via the machine control panel is convenient and easy. Thanks to SCHUNK's sealing concept, the clamping modules and as well as the pallet screw positions are protected against highly abrasive materials, and dust at all times. Production Manager Dominik Isele is satisfied: "With this clamping system, our machine does what it should: It mills around the clock." What he particularly likes is the absolute consistency. "Everything fits together, finding the solution with SCHUNK, the implementation of the design, and the flexible clamping system itself. This is a true all-round carefree package for us and is done simple and smart.”