Automation is the key to manufacturing productively and cost-effectively despite a shortage of skilled workers and cost pressure. But automation does not start in the machine. To fully exploit the machine's productivity potential, it is essential to ensure reliability and speed during loading and unloading. SCHUNK, the specialist in toolholding and workholding, gripping, and automation technology, offers an extensive portfolio of components, necessary for automated manufacturing inside the machine, as well as efor automated parts loading and unloading. At least as important: SCHUNK supports customers with well-founded component and application know-how in the selection and construction of the individually optimal automation solution.

From simple tool handling to intelligent machining

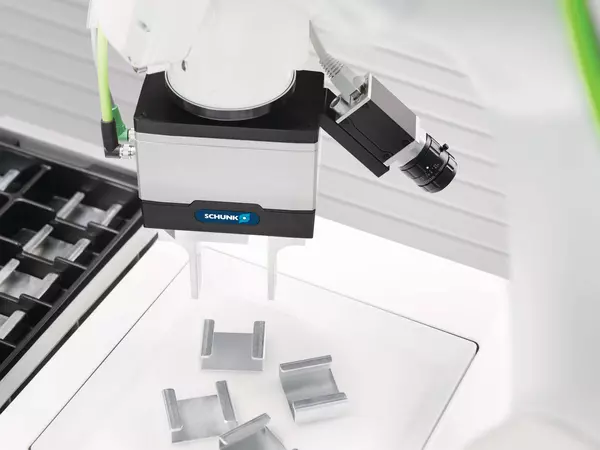

Which type of automation is the right one depends on a range of parameters. For example process chains, available space, batch sizes and part variance all play a decisive role. At AMB, SCHUNK will showcase diverse approaches of automated machine loading, from simple entry-level to high-end solutions. In addition, visitors will experience vivid examples of automated workpiece handling with innovative handling solutions. The 2D Grasping Kit, for example, which was honored with the HERMES Award 2024, enables a quick and easy introduction into the process-reliable automated handling of unsorted parts. Brand new is the mechatronic EZU centric gripper. The robust and durable gripper is perfect for harsh working conditions and handles cylindrical or eccentric positioned workpieces of various sizes without any loss of gripping force. Simple integration is ensured due to a large number of communication interfaces, PLC function modules and plug-ins for well-known robot manufacturers.

More freedom in workpiece clamping

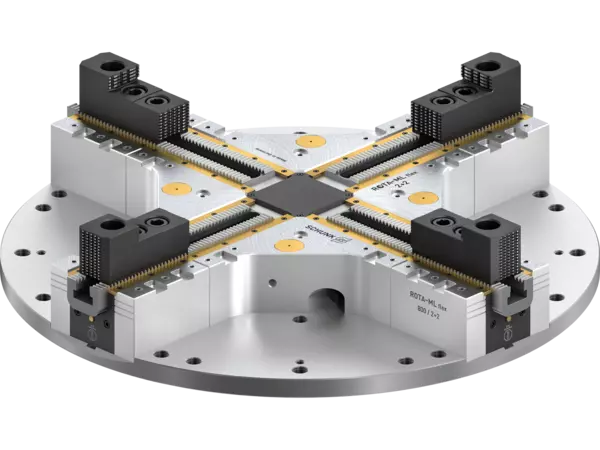

SCHUNK also offers manual, automatic and intelligent clamping solutions for almost any application in its product line for workpiece clamping technology. The existing product lines are continuously expanded and adapted to customer requirements. For example, with the flexible, manual 4-jaw compensating chucks ROTA-ML flex 2+2 any workpiece geometry can be clamped. The product range was revised from size 500 mm diameter: The chuck heights were reduced up to 30 percent, and therefore the chuck weight lowered up to 40 percent. This gives users significantly more freedom in terms of size and weight of the workpieces to be machined.

With the KONTEC KS-H-LH, SCHUNK launches a compact and powerful hydraulically actuated long-stroke vise with an overeall clamping force of 80 kN. Therefore, a clamping range of 20 to 345 mm is achieved with a hydraulic clamping stroke of 110 mm. In addition, data such as path measurement or dynamic pressure can be transferred to the machine control via IO-Link.

There are also new developments in the field of magnetic clamping technology: SCHUNK has reworked the proven MAGNOS MFRS magnetic chucks and equipped them with an additional digital feature:

A new ePaper status display provides users with information about the clamping statuses "MAG ON," and "MAG OFF" in future. This clamping solution ensures reliable clamping and maximum process reliability.

Intelligent process monitoring

There are alsonews in the area of intelligent process monitoring with iTENDO²: Its range of applications is being significantly expanded. Using the iTENDO² magnetic holder, customers can now place the intelligent real-time sensor freely in the machine room and use them for tests and process optimization. Another hydraulic expansion toolholder is now also part of the iTENDO² product range: The slim iTENDO² Slim 4ax in standardized heat shrinking contour also offers process monitoring options in fine machining. Both modules can be seamlessly connected to the basic pad version for evaluating the vibration data.

Automated and AI-supported for a "Healthy Factory"

These innovative automation and digitalization modules help to create healthy and economically successful production process. Timo Gessmann, CTO of SCHUNK summarizes: "Small and medium-sized industrial companies, in particular achieve a productivity boost with automation, which compansates for gaps in skilled labor and secures their global competitiveness. At the AMB, we will show ready-made solutions, but also how we at SCHUNK are already using artificial intelligence to increase process efficiency and boostour customers' productivity ."

We are looking forward to welcoming you at the AMB. Please visit us: Hall 1, booth 1G30.