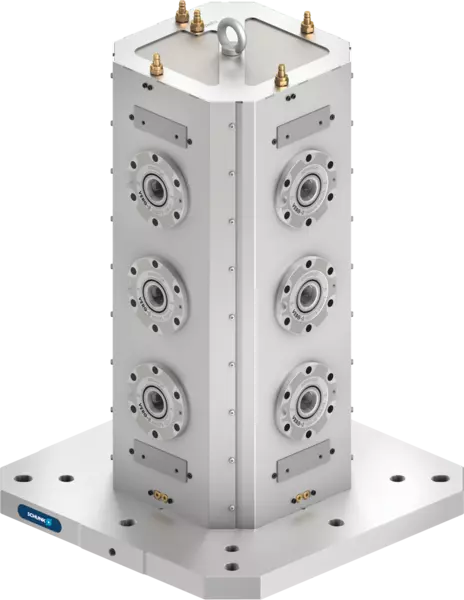

Hybrid tombstones

Hybrid tombstones

Tombstones with high vibration-reduction, composed of a mineral casting core embedded in a steel jacket.

Description

Advantages – Your benefits

- Excellent damping characteristics

Increase of the service life of cutting tools - Extensive design freedom regarding shape and sizes

Very fast and versatile in manufacturing - Low thermal conductivity

Only reacts slowly to temperature changes - Lower cost manufacturing than pure mineral casting

No design and manufacture of negative molds required - Lighter than steel or gray cast tombstones

Allowing higher payload on workpieces - High chemical and mechanical resistance

Application also possible for machining with aggressive and abrasive media

Options and special information

- SCHUNK tombstones in hybrid technology have a mineral casting core with a steel coating, and combine the benefits of both materials.

- SCHUNK tombstones in hybrid technology are composed of a mineral casting core and a steel shell. The outstanding characteristics of mineral casting include the low weight of the material and, most importantly, the excellent vibration damping. Due to the lighter material, the tombstones have a lower dead weight. Significantly heavier workpieces can be clamped and the maximum load capacity of modern table constructions can therefore be optimally utilized. The excellent damping properties in turn provide decisive economic advantages and enable higher cutting speeds with lower tool wear and the best surface quality.

- The excellent damping properties for example provide significant economic advantages and allow higher cutting speeds with a simultaneous low tool wear and best surface quality.

- The steel coating offers all of the unsurpassed characteristics and advantages that SCHUNK clamping bodies offer in stable hollow part design, by providing excellent material quality, perfect accuracy and finely milled mounting surfaces.