According to the report of World Robotics, 3.24% of the robots installed in 2018 were cobots; in absolute numbers, this is 14,000 out of 422,000. These figures conceal the fact that the segment is booming and is becoming very attractive for manufacturers and users alike – not least because of the pioneering role of Universal Robots. While more traditional industrial robots require a significant budget and a great deal of know-how, the flyweight category triggers the play instinct, partly because it is possible to work directly with the robot without any problems. Suddenly, users who never had anything to do with robots feel confident enough to create an application over the weekend. It is not just SMEs that were previously not involved in robotics that are jumping on the bandwagon. Even large automation-savvy corporations are succumbing to the charm of smart, lightweight robots, because suddenly applications can be opened up that previously did not justify an investment in conventional robot technology.

Simplification is the magic word that unleashes previously undreamed-of creativity when working with cobots. Construction, configuration, and design, assembly and installation have been so radically simplified by the manufacturers that even beginners find robotics useful and enjoy it. A wide variety of automation scenarios can be implemented on an experimental basis, either in separate rooms as with conventional industrial robots, or in the immediate vicinity of humans. Today, cobots are mainly used in their capacity as lightweight robots. They cost less than standard industrial robots and are significantly easier to program," explains Benedikt Janßen, Head of Product Sales Mechatronics at the gripping systems and clamping technology specialist SCHUNK. "They enable smaller companies in particular to make a low-level entry into robotics with a pragmatic approach to safety considerations. The head of the SCHUNK Co-act team has been following the development of the market for several years, and has experienced the new and dynamically growing world of lightweight robotics. "Traditional industrial robotics is implemented by system integrators and plant manufacturers, who especially appreciate SCHUNK's large gripping system portfolio and the high quality of our grippers and end-of-arm components. On the other hand, the front-end range for cobots, which are primarily distributed via retail or via retail platforms of cobot manufacturers, needs to be much leaner and more universally usable."

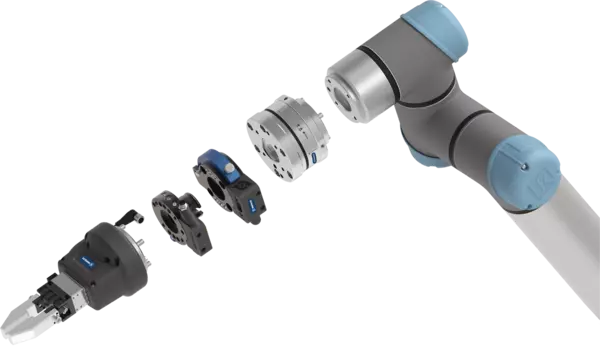

Grippers are often simply bought in with the cobot, unlike industrial robots, where they are individually selected, designed, and tailored by integrators and plant manufacturers for the respective application. Those taking their first steps in automation, in particular, are often overwhelmed when they look at the 1,800-page SCHUNK gripper catalog. "With our Plug & Work portfolios, we are now specifically bundling components that can reliably cover 80 percent of all cobot applications," says Janßen. "Users have the option to freely choose the components from these portfolios and they will always match with the corresponding cobot". The core goal is to enable users to achieve productive results quickly, cost-effectively and directly by bundling SCHUNK's expert knowledge in the portfolio components and avoiding over-engineering. Following the Plug & Work portfolio for Universal Robots, which was launched in 2018 and has long since established itself on the market, customized Plug & Work portfolios for Doosan Robotics and Techman Robot will be added by mid-year. Each include certified Co-act grippers for collaborative operation, pneumatic and electric grippers, sensors as well as change systems and cover a wide range of applications in both conventional automation and collaborative applications. The components are therefore available from stock at short notice and are equally suitable for newcomers to automation as well as for professionals in the metal-cutting industry; the automotive industry, the electronics industry, as well as many other industries.

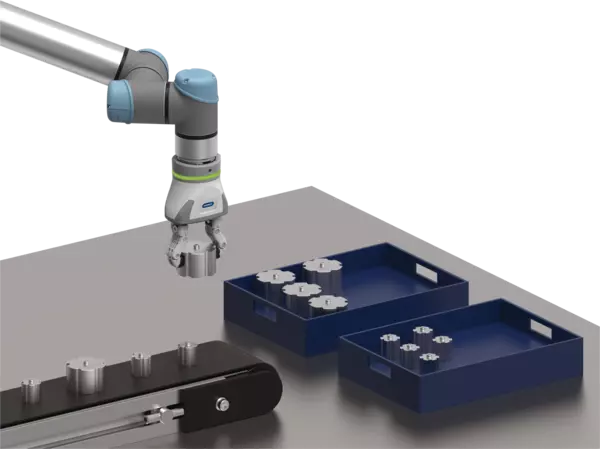

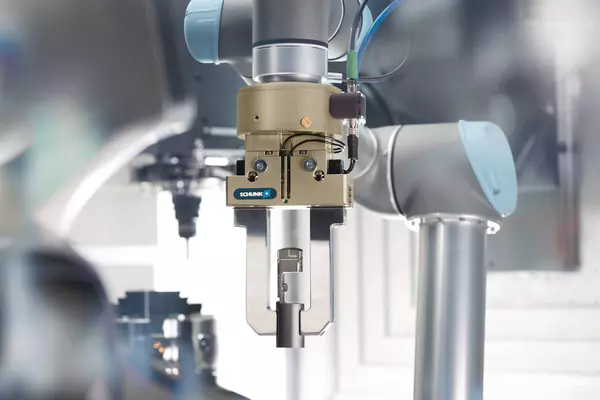

At the top of the collaboration scale in the Plug & Work portfolio of the SCHUNK Co-act EGP-C grippers for small components, of which several hundred units have already been successfully installed, and the long-stroke gripper SCHUNK Co-act EGL-C, which will be available as standard in the second half of 2020. Both meet the requirements of EN ISO 10218-1/-2 and ISO/TS 15066 and has been certified by the German Social Accident Insurance (DGUV) for use in collaborative applications. While the Co-act EGP-C with maximum finger strokes of 3 mm, 6 mm, 8 mm, and 10 mm and recommended workpiece weights with a force-fit gripping of 0.19 kg, 0.7 kg, 1.05 kg, and 1.3 kg is designed more for handling small components, the Co-act EGL-C with a maximum stroke of 42.5 mm per finger and variable gripping forces between 50 N and 450 N enables a significantly higher variance, as it is required in automated machine loading, for example. With force-fit gripping, the intelligent and sensitive gripper enables reliable processing of various, alternating parts of up to 3 kg – including parts that are heavy or are sensitive to deformation. Workpiece weights of up to 8 kg can be gripped in a form-fit manner.

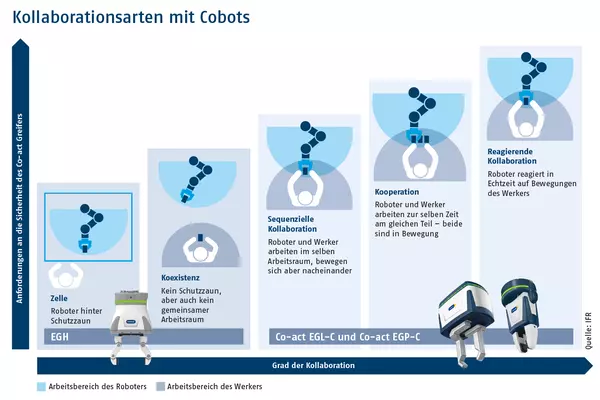

The interdisciplinary SCHUNK Co-act team has already gained a great deal of experience with projects in the field of human-robot collaboration. It has become clear that the chances for success increase significantly with a soft start. "Cobots are an excellent means of gradually increasing the degree of collaboration," emphasizes Benedikt Janßen. "Those who have already gained experience in coexistence or sequential collaboration will find it easier to implement collaborations or even responsive collaborations in later steps. The higher the degree of collaboration, the more likely we are to recommend a greenfield implementation, i.e. in completely new applications. Applications with a low degree of collaboration, on the other hand, can also be implemented very well in brownfield environments (i.e. in existing environments"). In principle, the HRC specialist recommends making use of SCHUNK's expertise. "Our team bundles HRC experience from different sectors, enabling us to avoid many mistakes in advance".