SRM

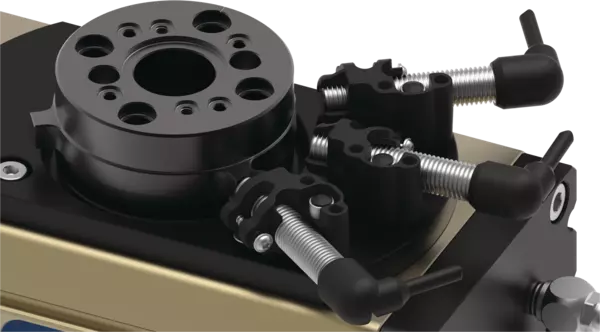

Funktion

Disegno in sezione

Disegno in sezione

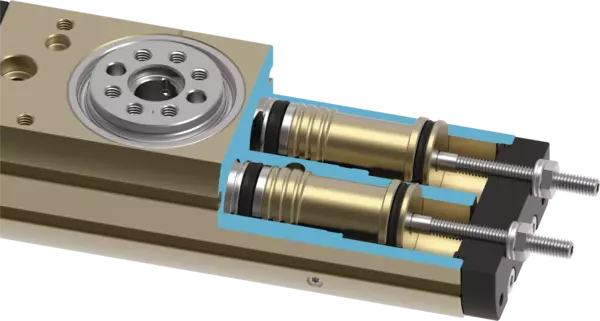

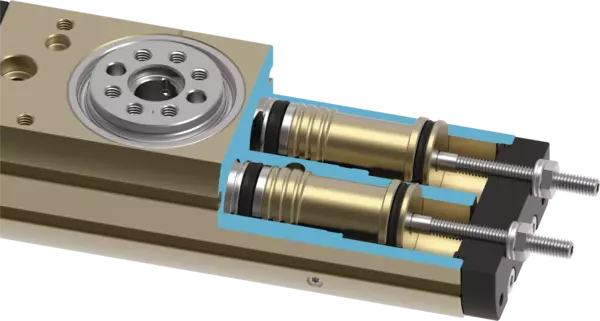

Entrambi i pistoni pneumatici, all'applicazione di pressione delle rispettivi superfici frontali, si muovono in linea retta all'interno dei loro fori ruotando il pignone tramite la relativa dentatura montata lateralmente.

- 1

-

Corpo

a peso ridotto attraverso l'impiego di lega di alluminio anodizzata dura e ad alta resistenza - 2

-

Pignone

Pignone robusto per la trasformazione del moto del pistone in moto rotatorio - 3

-

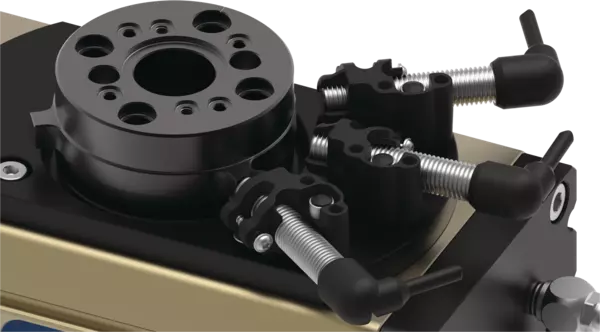

Regolazione dell'angolo di rotazione

per poter regolare la posizione finale in modo rapido, semplice e intuitivo - 4

-

Damping

Hydraulic shock absorbers for high moments of inertia - 5

-

Drive

Pneumatic, powerful double piston drive - 6

-

Bearing

play-free, pre-loaded bearing

Versions with small end position adjustability

Version avec possibilité de réglage large de la position finale

Version avec position intermédiaire pneumatique

Palier du pignon

Ajustement de la position finale et de la course d'amortissement

Versione con smorzamento esterno

Variant with media feed-through

Variant with electric rotary feed-through

Monitoring via electronic magnetic switches

Monitoring via inductive proximity sensors and adjustable control cam

Monitoring via inductive proximity sensors and fixed control cam

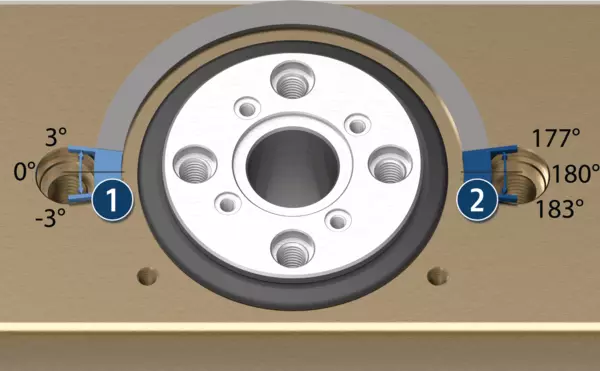

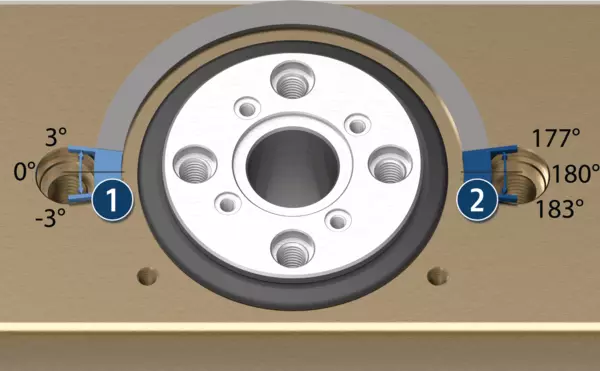

Versions with small end position adjustability

Slight end position adjustability for fine adjustment of both end positions (±3°) in case of swivel units with a swivel angle of 180°

- 1

-

Adjustment range starting angle

- 2

-

Adjustment range end angle

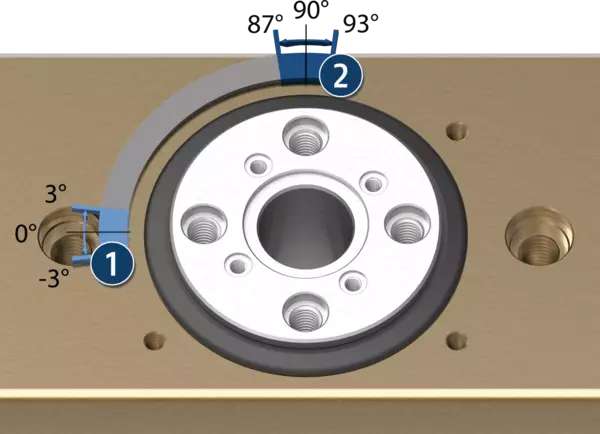

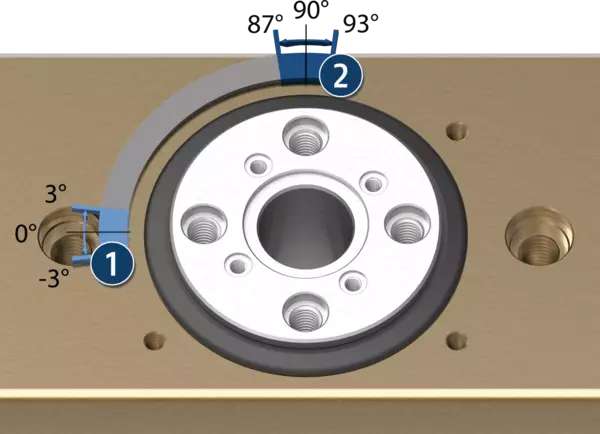

Slight end position adjustability for fine adjustment of both end positions (± 3°) in case of swivel units with a swivel angle of 90°

- 1

-

Plage d'ajustement angle de départ

- 2

-

Plage d'ajustement angle de fin

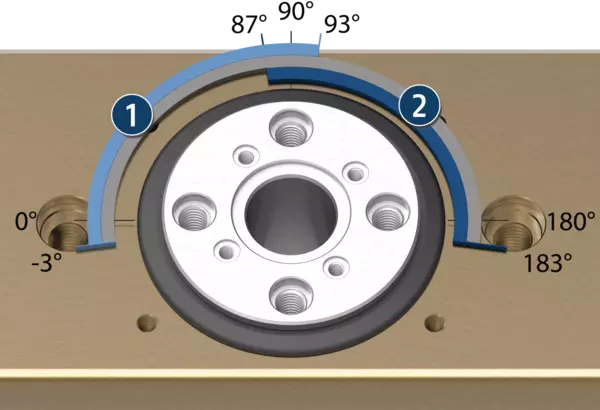

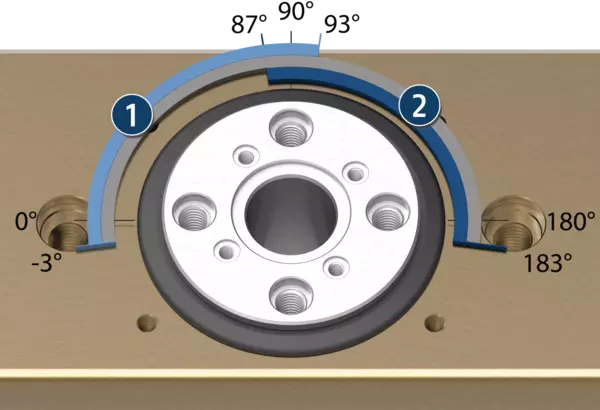

Version avec possibilité de réglage large de la position finale

Ajustement large pour un réglage de l'angle de rotation entre 0° et 186°. Les deux positions finales peuvent chacune être limitées de 90° (±3°).

- 1

-

Plage d'ajustement angle de départ

- 2

-

Plage d'ajustement angle de fin

Version avec position intermédiaire pneumatique

L’unité de rotation SRM peut être commandée en option avec position intermédiaire pneumatique. Cela permet une troisième position en plus des deux positions finales.

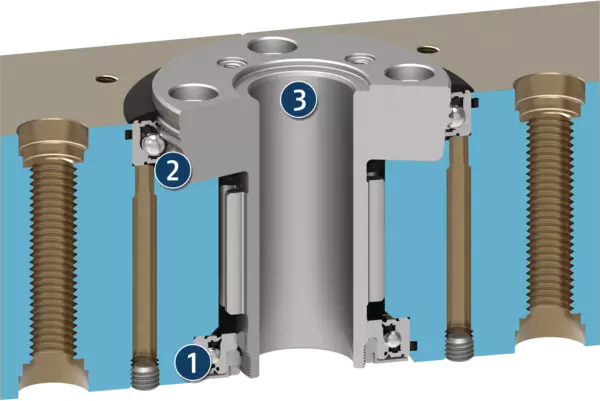

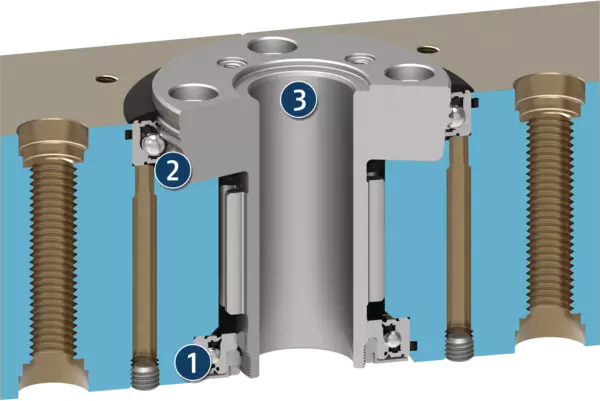

Palier du pignon

Le pignon de l'unité de rotation SRM est entraîné par deux pistons et est fixé sur deux points. Le palier supérieur est intégré dans le pignon, de ce fait une hauteur minimum de l'unité complète est atteinte. Le palier inférieur est préchargé sans jeu, de ce fait une très haute précision et rigidité de palier est atteinte. Les deux paliers sont étanches à l'environnement extérieur avec des doubles joints à lèvres fabriqués en FKM solide et durable.

- 1

-

Palier préchargé à double joints à lèvres

- 2

-

Palier intégré à double joints à lèvres

- 3

-

Grand alésage central pour le passage de câbles et de flexibles

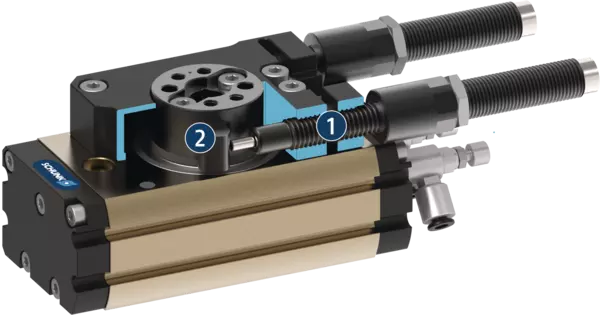

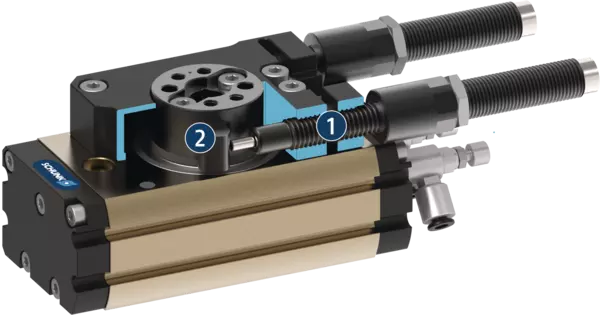

Ajustement de la position finale et de la course d'amortissement

Les deux positions finales et la course d'amortissement peuvent être ajustées manuellement sur l'unité. En raison du préréglage en usine de la course d'amortissement, son réglage n'est pas nécessaire pour de nombreuses applications. Les repères sur le couvercle indiquent le sens de rotation sur l'ajustement de l'angle de rotation

- 1

-

Regolazione della corsa dell'ammortizzatore

- 2

-

Regolazione della posizione finale

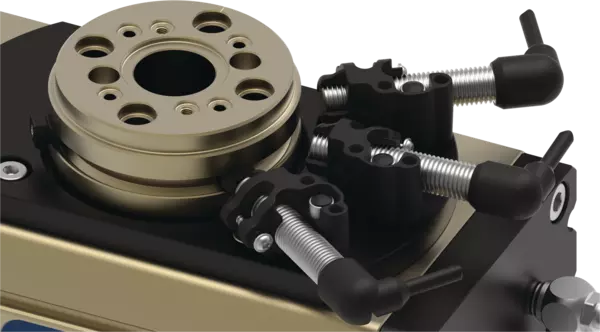

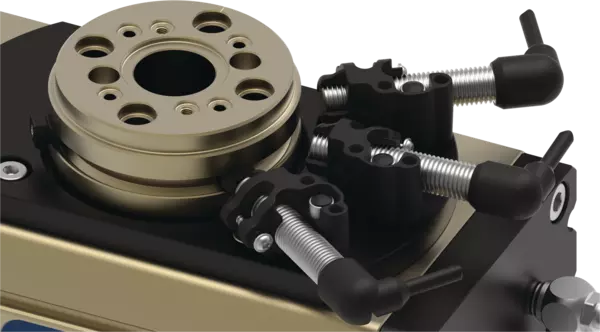

Versione con smorzamento esterno

Nella variante di base del SRM, il movimento dei pistoni di azionamento viene smorzato da ammortizzatori nella camera del pistone. Nella variante con smorzamento esterno, gli ammortizzatori sono montati sul lato di uscita dell'unità. Qui, il movimento viene smorzato direttamente sull'alimentatore rotativo. Ne consegue la possibilità di realizzare momenti di inerzia e una precisione di ripetizione maggiori. Inoltre, in tutte le posizioni è disponibile la coppia piena.

- 1

-

Ammortizzatore idraulico

- 2

-

Alimentatore rotativo con arresto meccanico

Variant with media feed-through

The SRM swivel unit can optionally be equipped with a media feed-through, which enables process-reliable feed-through of compressed air, gases, or vacuum. In case of sizes 10, 12, 14, and 16, the media feed-through can be optionally routed through the center bore, and in turn is covering it. In case of sizes SRM 20, 25, 32 and 40, the large center bore is completely intact, even if the option media feed-through is chosen.

- 1

-

Connection for the set-up to be swiveled, equipped with fluid feed-throughs

- 2

-

Connection fluid feed-throughs fixed part

Variant with electric rotary feed-through

The swivel unit SRM can optionally be equipped with an electrical rotary feed-through, thus ensuring operationally reliable feed-through of electrical signals. The electric rotary feed-through is equipped on both sides with standardized and color-coded M8 or M12 cable plugs. This makes it easy to identify the signal flow and simplify commissioning.

- 1

-

Plug connector on the driving side, 4-pole, color coded

- 2

-

Plug connector on the driven side, 3-pole, color coded

- 3

-

Plug connector on the driven side, 4-pole, color coded

Monitoring via electronic magnetic switches

There are two C-slots on each side of the SRM swivel unit, into which the SCHUNK electronic magnetic switches MMS can be inserted. This ensures flexible monitoring of the end positions, regardless of the installation position of the SRM.

- 1

-

Monitoring with magnetic switch on the back of the swivel unit

- 2

-

Monitoring with magnetic switch on the front of the swivel unit

Monitoring via inductive proximity sensors and adjustable control cam

To monitor the end positions of the swivel unit with inductive sensors, an additional set-up is mounted onto the rotary table. For flexible monitoring of individual swivel angles, a version with adjustable control cam is available. This allows up to three positions to be inductively monitored.

Monitoring via inductive proximity sensors and fixed control cam

For simple commissioning and maintenance of inductive monitoring, a version with a fixed control cam is also available. This is not adjustable and therefore only available for swivel angles of 180° or 90°. As a result, monitoring of up to three positions is possible.

Application example

Application example

Swivel unit with electrical and pneumatic feed-through and double gripper for loading and unloading a machine tool

- 1

-

Universal rotary actuator SRM

- 2

-

Tolerance compensation unit TCU

- 3

-

Universal gripper PGN-plus-P

- 4

-

Inductive proximity switches IN

- 5

-

Magnetic switch MMS

- 6

-

Universal linear module Beta with toothed belt drive