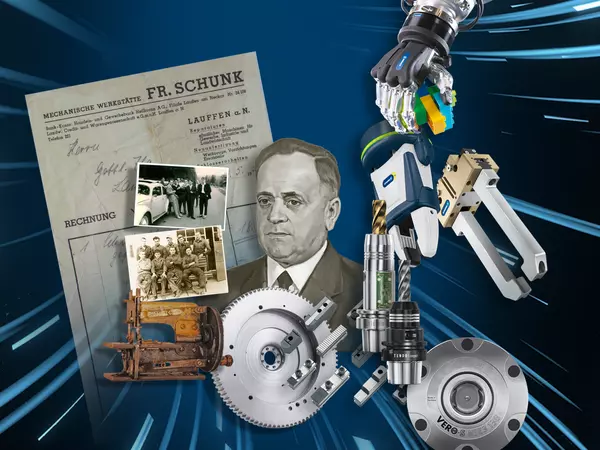

It all started in 1945 with the purchase of a used lathe. Friedrich Schunk used it to manufacture spare parts for machines on a commission basis after the war. A converted garage in Lauffen am Neckar served as his workshop. The Second World War had just ended and there was a lot to do. He soon made a name for himself with his own inventions. After a short time, the name SCHUNK stood for innovative inventions that were high quality and durable, such as the lampshade punching machine invented by Friedrich Schunk. As a result, more and more companies in the area commissioned the resourceful inventor to make their machine production more efficient or to supply special components.

In 1964, NSU Motorenwerke AG from Neckarsulm (Audi AG today) came knocking on Friedrich Schunk's door. The company, which at the time specialized in motorized two-wheelers, had also started developing small cars in the mid-1950s and was looking for a suitable supplier to produce a passenger car model. Friedrich Schunk accepted the challenge and moved his business into a large, newly constructed hall. From now on, he machined 3,000 clutch drums and flywheels per month for the NSU Prinz 4. In the same year, Friedrich Schunk's son, Heinz-Dieter Schunk, joined the company.

Heinz-Dieter Schunk, who was 22 at the time, introduced his own product lines, and set up a sales department. SCHUNK developed into a competent partner in workpiece clamping for the processing industry. The company also quickly made a name for itself in tool clamping under his leadership. The TENDO hydraulic expansion technology was a milestone, as was the TRIBOS polygonal clamping technology for automated part machining. Only new developments move a company forward. Heinz-Dieter Schunk has always been aware of this.

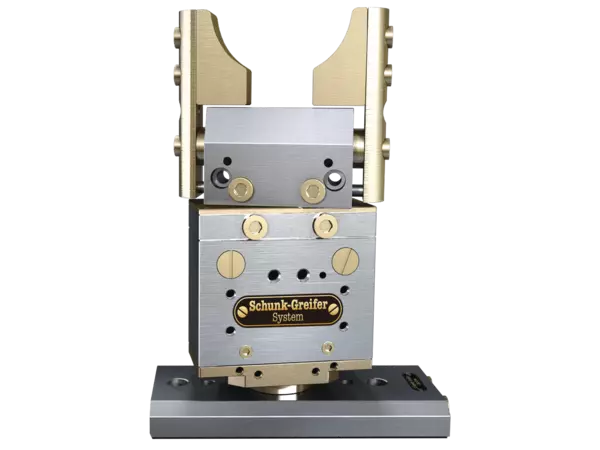

In 1982, Heinz-Dieter Schunk discovered the first robots equipped with a gripper during a visit to a trade show. He realized that the components for the robotic arms were still far too heavy and made the set-up unstable. This observation evolved into the idea that the market needed a light and simple solution. That was the birth of the field of gripping technology and the next development step for the company. As one of the first manufacturers, SCHUNK then began its development of standardized gripping technology.

Increasing demand in North America provided an opportunity to expand in the early 1990s. Another production site was established in Raleigh, the capital of North Carolina, USA in 1992. SCHUNK then took over Hage GmbH in Mengen in 1994 and expanded the product portfolio to include lathe chucks. Today, the grandchildren of the company founder, Kristina I. Schunk and Henrik A. Schunk are leading the company. The customer base now includes all the well-known companies in the mechanical and plant engineering sector, virtually every European automotive manufacturer, and numerous companies in the aerospace, life science and consumer goods industries.

The pioneering spirit that runs through our company history as a common thread remains unbroken to this day. In the age of Industry 4.0, people, machines and products are all interconnected. We are actively involved in shaping this development: In the form of digital services, smart product functions and our commitment to creating a legal framework and uniform standards.

For the automation of production processes, we are not only supplying individual components but also the corresponding software modules. With our applications, we develop intelligent functions for every need and are therefore opening up completely new areas of application. We often combine several components to create application-specific solutions. This means that the functional scope of our products is continuously growing. We validate these customer applications in CoLabs – our robot application centers – and coordinate them so that our customers can enjoy simple plug-and-play solutions. We also integrate components from external suppliers, such as robot arms or cameras, into our applications.

Whether robotics, AI or automation – technologies are developing more rapidly than ever before. This results into enormous opportunities and scope of design for the future.